Update: Originally posted in 2018, this blog was updated with new context on 29/04/2024.

Industrial wear applications create exacting conditions for equipment and components due to the inherent abrasiveness, corrosiveness, or high temperature and oxidation resistance damages associated with these specific processes. Sandblasting, for example, is a surface preparation method that blows abrasive grit through shot blast nozzles at high velocities to change the surface texture or roughness of an object. This grit, comprised of tough substances such as cast iron or chill-cast iron, has the capacity to erode the interior components of the abrasive blaster – particularly at the outlet. Shot blast nozzles and their liners must, therefore be composed of high-strength materials capable of withstanding long-term abrasive conditions from high concentrations of small particle erosive elements.

What is a Blasting Nozzle?

A shot blasting nozzle is a durable component that accelerates air and an abrasive media over a material’s surface. Conventional shot blast nozzles have been manufactured using high-strength metal compounds such as tungsten carbides (WC), an exceptionally hard industrial metal known for its wear-resistant and corrosion-resistance properties, with double the strength and density of steel. However, tungsten carbide owes these properties to pliable cobalt molecules cementing the tough carbide grains together. These comparably soft particles can exhibit wear over time due to continuous corrosion from low-angle impacts of various particles used in hot blasting, such as alumina. Continuous exposure to such high-velocity media will exhibit significant wear on shot blast nozzles made of traditional materials.

Using Sialon Shot Blast Nozzles

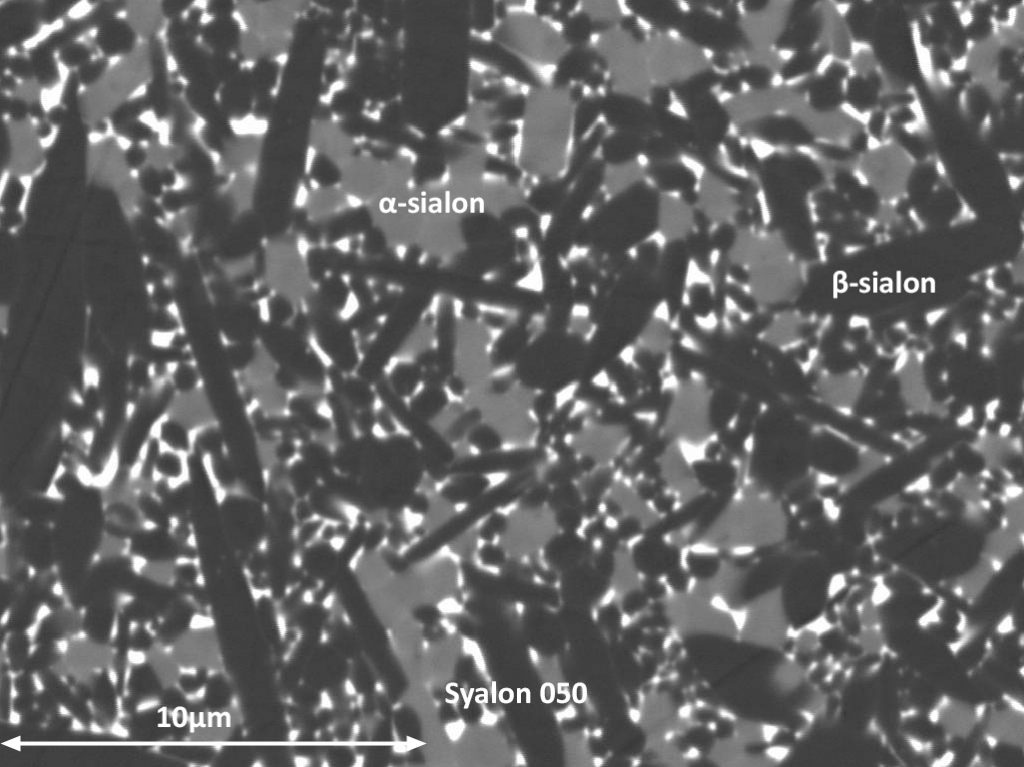

Sialons, as a solid solution including silicon nitride (Si3N4) are uniquely capable of withstanding such high temperature and abrasive conditions, with excellent wear-resistant properties and long service life capabilities. Shot blast nozzles have been formulated from high toughness Syalon 050, a mixed α-β (alpha-beta) ceramic material with a hardness value of 94 HRA and a porosity value of 0%. These components are capable of vastly outperforming conventional materials, with proven operation capacities of over 1000 hours under operating conditions with chill-cast iron grit at 100psi.

Why Sialons are Ideal for Industrial Wear Applications

The revolutionary mechanical strength and ultimate tensile strength of sialons have encouraged manufacturers to implement sialon ceramic products for a broad range of wear applications, including sand blast nozzles; grinding media for sample preparation; dewatering foils for paper manufacturing; extrusion dies for molten aluminium processing; and more.

Choosing the Best Shot Blast Nozzle Materials

International Syalons is the UK’s leading manufacturer of sialon ceramics and related products for an enormous range of applications. We are dedicated to improving the applicable properties of these high-strength and good versatility products by maintaining a consistently improving range of sialon materials, including:

- Syalon 101: Syalon 101: broad strengths and resistances, for use in wear industries as protection sheaths and milling media;

- Syalon 050: extreme compressive strength and resistant properties, is commonly used to manufacture sand blast nozzles;

- Syalon 110: outstanding thermal shock resistances, ideal for thermocouple protection in high-temperature applications;

- Syalon 201: great strength retention, suitable for die casting and refractory materials;

- Syalon 501: electrically conductive, offers advantages in electrical and thermal applications.

If you believe our syalon materials are applicable for your industrial wear application, or would like more information about our syalon shot blast nozzles, please do not hesitate to contact us.