SILICON CARBIDE CERAMIC

Silicon carbide (SiC) is one of the hardest technical ceramics available. For many years it was second only to diamond on the Mohs scale, and to date, sintered silicon carbide remains both a competitive and supplementary material for abrasive synthetic diamonds. Combined with its high thermal conductivity and superb corrosion resistant properties, silicon carbide ceramics are workhorse materials for challenging application areas.

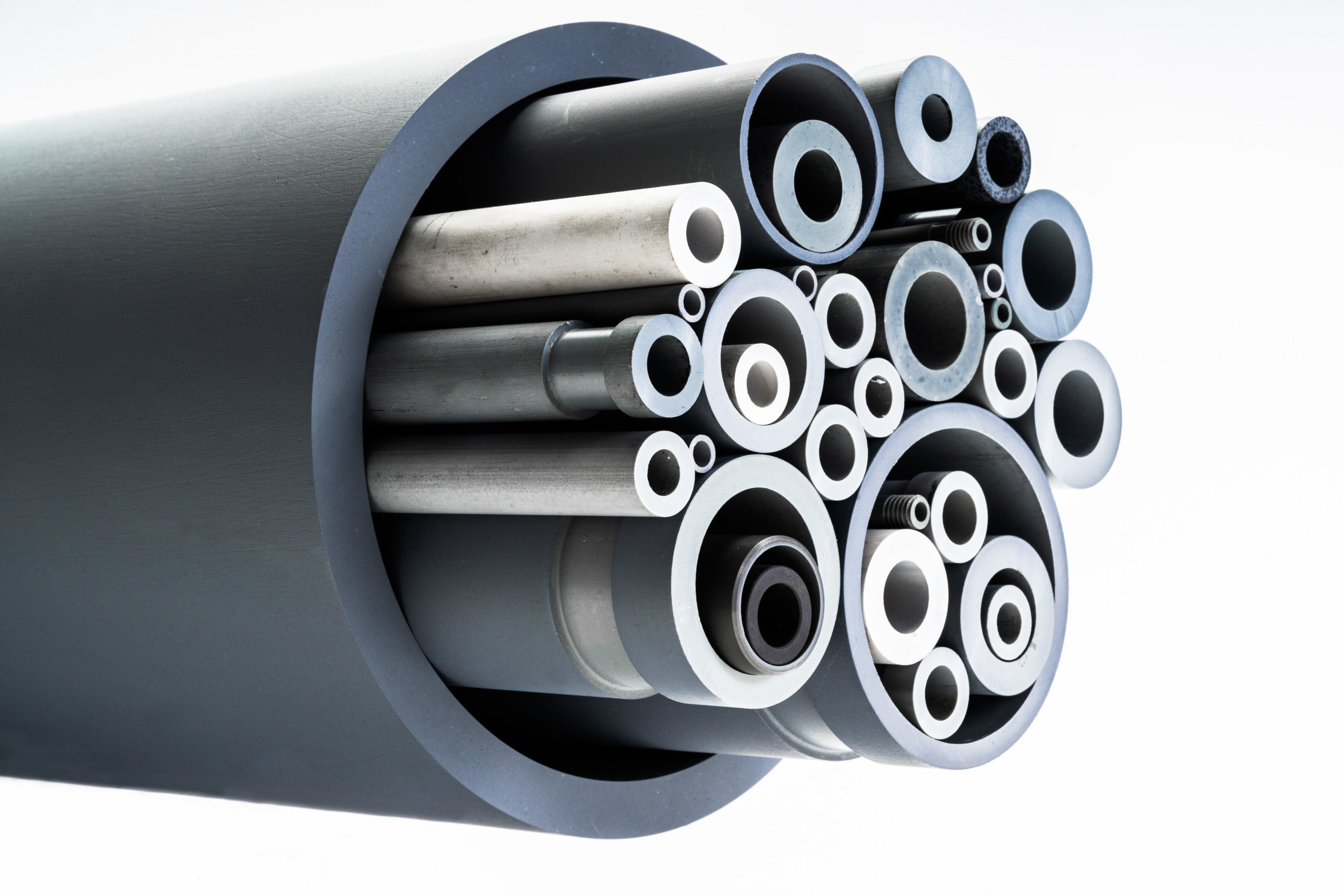

At International Syalons, we offer high-performance silicon carbide ceramics via reaction bonding and sintering. Each manufacturing technique yields a precision zero-porosity ceramic with exceptional resistance to chemical attack and good high-temperature properties. These result from a robust atomic structure with carbon and silicon forming a strong tetrahedral lattice. The advantages of this include:

- Unmatched hardness (2600 Kg/mm2)

- Superior thermal conductivity (150 W/(mK))

- Moderate thermal shock resistance (ΔT = 400°C)

- Good flexural strength at high temperatures (450 MPa at 1000°C)

Sintered silicon carbide is engineered via conventional means, using non-oxide sintering aids and high-temperature forming process in inert atmospheres. Reaction bonding differs in that additional silicon is made to infiltrate the green body to form additional SiC grains that bond with the primary ceramic. The latter is typically used to increase thermal shock resistance.

Explore our silicon carbide products below where you will find full specifications and a table detailing comprehensive behaviours in acids and alkalis.

Sycarb 10

The table below lists typical mechanical, thermal and electrical property data for Sycarb 10.

Download the Sycarb 10 Property Datasheet

Sycarb 10 - Physical Property Data

Sycarb 20

The table below lists typical mechanical, thermal and electrical property data for Sycarb 20.

Download the Sycarb 20 Property Datasheet

Sycarb 20 - Physical Property Data

In addition to this outstanding property data, Sycarb also has excellent resistance to corrosion, often required for applications in the chemical and process industries.

The table below show the corrosion resistant behaviour of Sycarb in various acids and alkalis.

Sycarb - Corrosion Behaviour in Acids and Alkalis

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

In addition, see our resources section for guides on designing with ceramics and more property data comparing silicon carbide with other engineering ceramics. For a comparison of the physical properties of all our materials see our Material Properties Datasheet.

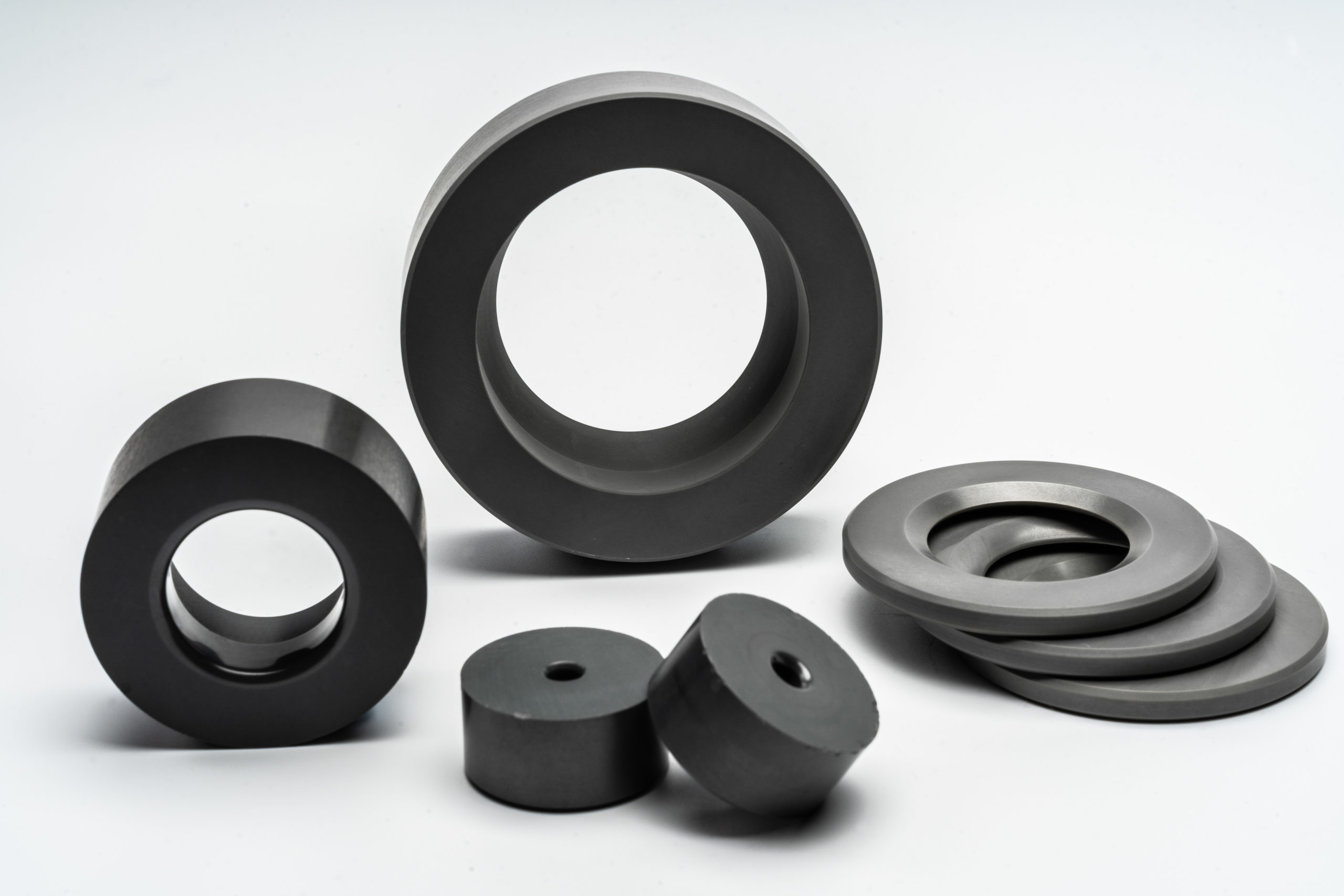

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries.

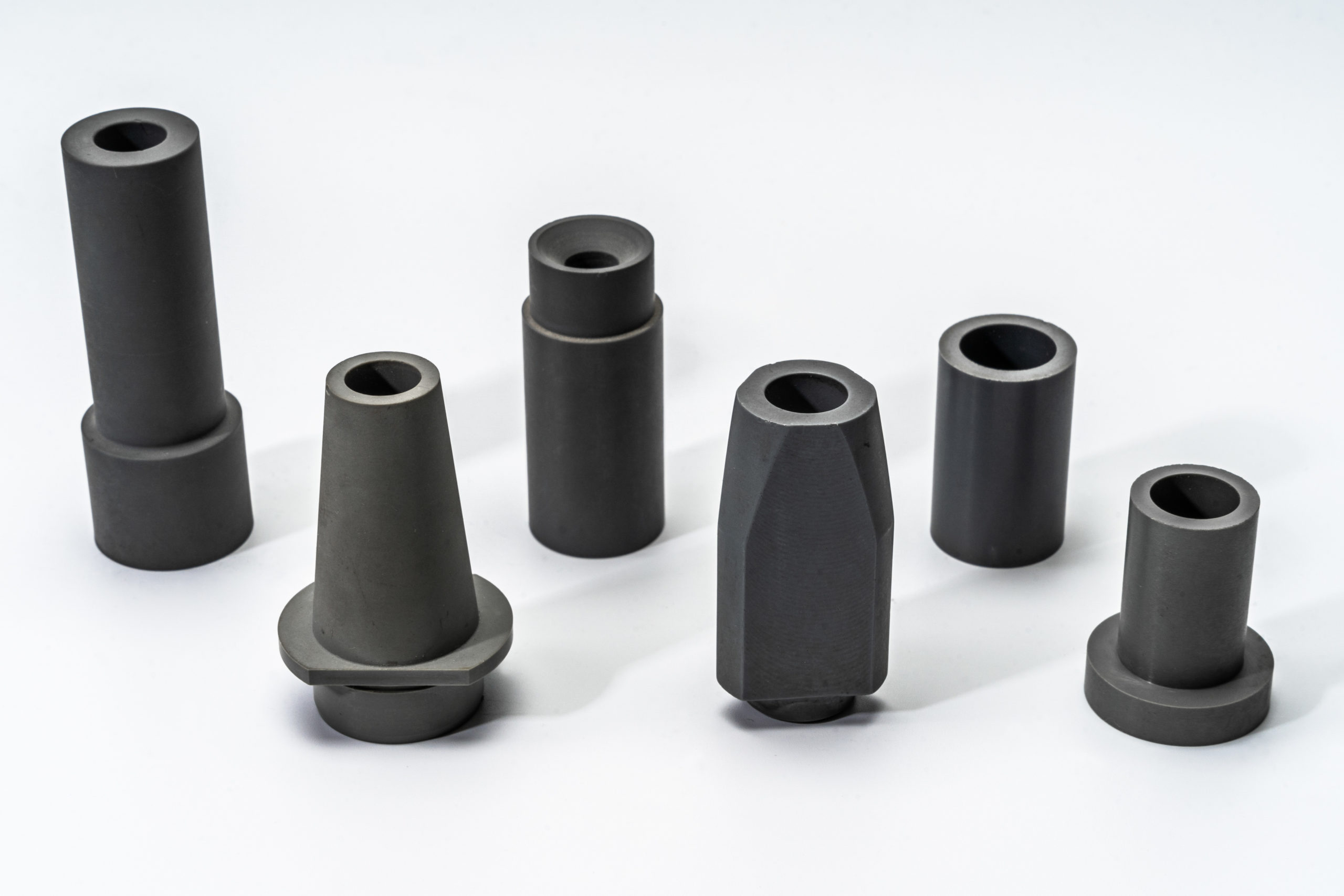

Syalon is the preferred choice when looking to improve nozzle wear resistance, outperforming many competitive materials such as alumina and tungsten carbide.

International Syalons manufacture a range of bespoke silicon nitride dies, which are used for high volume extrusion and drawing of copper and non-ferrous tube, rod, and wire products.