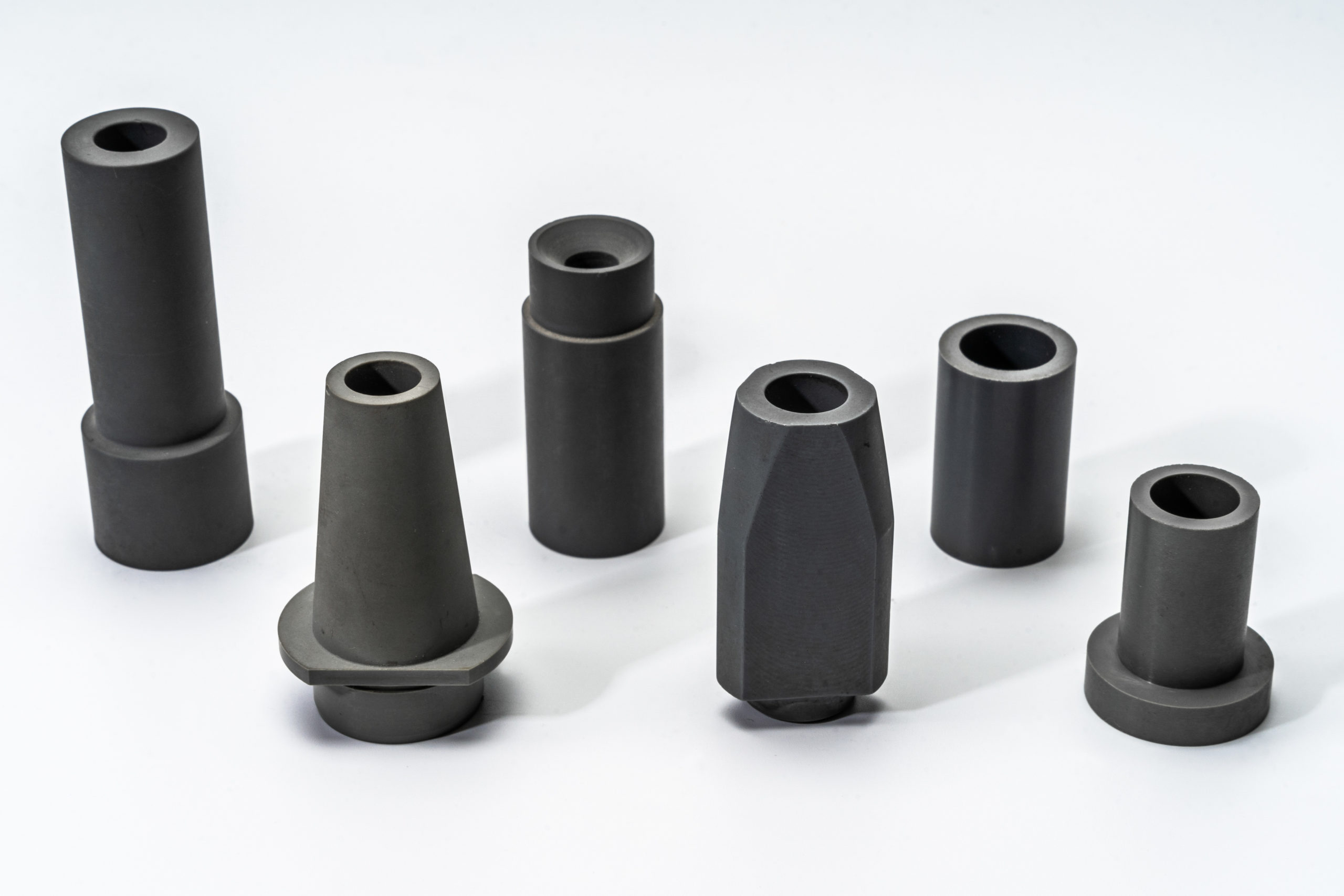

CERAMIC NOZZLES

Hot (or sand) blasting is a method of surface preparation or cleaning. It involves blasting an abrasive grit, such as sand, alumina or chill-cast iron, at high velocities at the surface to be treated through a nozzle which is lined with wear resistant material. Sialon and silicon nitride advanced ceramic shot / sand blast nozzle liners are extremely effective in this application.

Sialons are alloys of silicon nitride and possess outstanding wear resistant properties. The shot / sand blast nozzle liners must be extremely wear resistant. International Syalons manufacture a range shot / sand blast nozzles from Syalon 050, which has a high hardness, fracture toughness and Young's modulus, resulting in excellent wear resistant properties.

Traditionally liners have been made from tungsten carbide. However, at the low angle impacts encountered in many blasting operations, tungsten carbide wears excessively due to the erosion of the relatively soft and ductile cobalt used to cement the carbide grains together.

Syalon 050 has been shown to outperform many competitive materials, such as alumina and tungsten carbide. For example, a standard 3/8" nozzle tested using chill-cast iron grit and operating at 100psi performed for more than 1000 hours without appreciable wear.

Syalon 101 is also used in a variety of high temperature, wear intensive industries as a cost effective consumable nozzle compared with metal or low strength ceramic alternatives, including in the production of metal powder or as a protective shroud for gas firing applications.

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

Download our Industrial Wear Applications brochure for more details.

For advice on how best to incorporate technical ceramics into existing manufacturing processes see our Resources section for a range of useful articles and guides.

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.

Silicon nitride offers excellent corrosion and thermal resistance and are ideal materials for use in the chemical and process industries.