Weld location pins, or control pins, are hard-wearing and heat-resistant components that are used to precisely locate a material on one or more dimensional planes. Once fixed into position, the material can be accurately welded and, if necessary, moved along pre-determined axes for machining processes with high degrees of precision. This method is primarily used to weld captive nuts to sheet metal or body panels, for manufacturing parts that are used in various automotive and construction sectors.

Metal joinery occurs at exceptionally high temperatures, with peak flame impingement temperatures in the region of 3,500°C (6,500°F). Surrounding ambient temperatures are naturally heightened, and the process itself will emit potentially corrosive mixtures of ionized gas and particles. These conditions require components formulated from the most mechanically and chemically stable materials possible, including weld location pins capable of withstanding high temperatures, extreme thermal shock, and corrosion from metal abrasion and potential corrosion from effluent fumes.

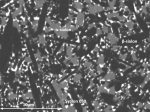

While alumina weld location pins have been used in the past, ceramic and synthetic components have become more prevalent due to their improved resistances and high-strength characteristics.

Sialon Weld Location Pins

Sialon weld location pins are manufactured from advanced silicon nitride ceramics. They are developed using Syalon 101, a beta-sialon type ceramic with exceptional properties for use in metal forming applications. It features a hardness of 92 HRA, a thermal shock resistance of Δ900°C, and outstanding levels of chemical stability. These mechanical strengths have cemented Syalon 101 weld location pins as a leading component for metal forming in the automotive industry, with 20 years’ experience supporting leading auto engineers around the world.

Zirconia Weld Location Pins

Zirconia weld location pins are typically manufactured using Zircalon 5 or Zircalon 10, both of which exhibit hardness values of 91 HRA. They feature improved toughness values and a lower thermal conductivity than sialon weld location pins, but they are not as adept at withstanding thermal sock as sialon ceramic components.

Read More: Zircalon 30 – A New Grade of Fracture-Resistant Zirconia for Welding

Both sialon and zirconia weld location pins display optimum properties for different applications, with a broad range of sizes and shapes available to suit varying assembly arrays.

Weld Location Pins from International Syalons

International Syalons are leading developers of advanced ceramic materials for industrial applications, championing the use of improved ceramic materials in various engineering disciplines. Our excellent resistant materials can be produced as standardized products, or made to bespoke specifications depending upon your requirements. Enquire about our ceramic weld location pins today.