Advanced sialon ceramics are engineered for numerous high-temperature applications, competing with established technical ceramics and refractory materials with their high strength and durability characteristics. These mechanical attributes are accompanied by outstanding thermal shock resistance, providing supreme physical stability under various thermodynamic conditions.

This article will explore the importance of thermal shock resistance in high-temperature applications while outlining the thermal shock properties of sialon ceramics:

What is Thermal Shock Resistance?

Thermal shock resistance refers to a material’s ability to withstand the strain of abrupt and significant temperature variations. Sharp thermal gradients can cause a material to warp through inconsistent expansion or contraction. If the strain of a thermal shock exceeds the strength of the material, it can result in mechanical deformation, cracking, and premature component failure.

Thermal shock resistance is quantified as a change of temperature (ΔT °C) and is calculated by determining the difference between a ceramic’s maximum temperature use and the temperature of the quenching media. These differences are controlled by the material’s thermal conductivity and the heat transfer coefficient between a ceramic and the cooling material. The full formula for determining what is known as the thermal shock parameter requires the thermal conductivity, tensile strength, and Young’s modulus of a material.

Why is Thermal Shock Resistance Important?

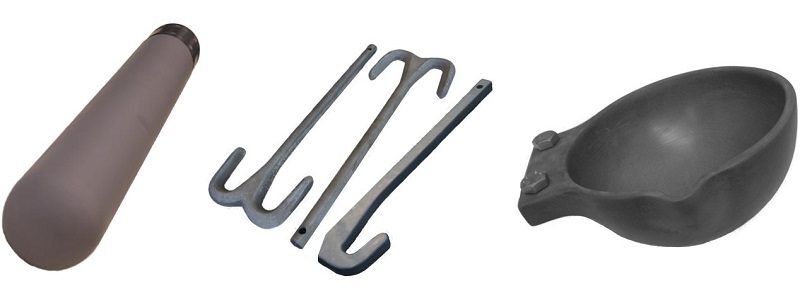

Materials with high thermal shock resistances are integral for refractory components that experience rapid changes in temperature. Molten metal crucibles, hot-dip ceramic hooks, and thermocouple protection sheaths are routinely manufactured to resist abrupt temperature gradients. The metallurgical and energy sectors regularly require high thermal shock-resistant ceramics for these specific applications.

The Thermal Shock Resistance of Ceramics

Advanced sialon ceramics exhibit such outstanding thermal shock resistance due to their low thermal conductivity, high peak temperature capacities, and their outstanding mechanical strengths. These qualities result from the high-density composition of the material, which is formed of tough interlocking covalently bonded grains of silicon nitride.

There are several grades of sialon ceramics available from International Syalons, with distinct thermal shock-resistant qualities. These include:

- Syalon 101: an advanced ceramic with outstanding strength values and a maximum use temperature of 1200°C (2192°F) and a thermal shock resistance of ΔT = 900 °C when quenched in cold water;

- Syalon 110: featuring a thermal shock resistance of ΔT = 800 °C for cold water quenching and an exceptional maximum use temperature of up to 1450°C (2642°F);

- Syalon 050: a wear-resistant ceramic with extreme abrasive resistance and high mechanical stability at temperatures up to 1450°C, displaying a thermal shock resistance of ΔT = 600 °C for cold water quenching;

- Syalon 501: an electrically-conductive sialon grade suitable for intricate component machining, with a thermal shock resistance of ΔT = 400 °C for cold water quenching.

Sialon Ceramics from International Syalons

International Syalons has been intrinsically involved in the ongoing development of advanced sialon ceramic materials. We were the first company to patent and develop sialons for industrial applications, providing a new material solution for high-temperature and abrasive applications. Our sialon grades feature distinct hardness profiles and thermal properties for varying applications, with good degrees of formability across the entire material family.

Learn More: Thermal Expansion Coefficient of Sialon Ceramics

If you would like any more information about the thermal properties of our sialon ceramics, please do not hesitate to contact us.