Thermocouple protection sheaths, sometimes called thermocouple tubes, are often fabricated from high-performance refractories such as high-temperature alloys, silicon carbide, and alumina. However, these materials can struggle to compete with advanced silicon nitride alloy ceramics or sialons. This article explores the benefits of sialon thermocouple protection sheaths in more detail.

What is a Thermocouple Sheath?

A thermocouple protection sheath is a high-strength insulator designed to protect thermal sensors in extreme temperature conditions. These sheaths are designed as robust cylindrical elements that encapsulate the thermocouple and protect the wiring from process gases, other corrosive media, and mechanical abrasion. A small aperture allows the wiring junction to transmit electronic signals proportional to the temperature values from within an open or closed system, enabling high-stability monitoring of process temperatures in demanding environments such as non-ferrous molten metal handling.

Why Use Sialons for Thermocouple Protection?

Sialons are unique refractory ceramic materials comprising exceptional thermal shock resistance of up to ΔT = 900°C and excellent mechanical stability at temperatures of up to 1400°C (2552°F). These inimitable characteristics make the material ideally suited for high-temperature applications featuring mechanically degrading media such as process gases and molten metals. Therefore, they make exceptional thermocouple sheath materials.

Several grades of sialon ceramics are suitable for thermocouple protection sheath manufacturing, with distinct thermodynamic properties for varying application requirements.

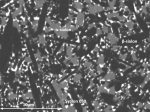

Syalon 101 is a beta-sialon ceramic with incredible mechanical strength values and a thermal conductivity of 28 Watts per meter-Kelvin (W/mK). It is non-wetting to many non-ferrous metals including aluminum (Al) and zinc (Zn), enabling highly-precise constant temperature measurement of molten alloys with reduced maintenance requirements for slag or dross removal. Syalon 101 thermocouple protection sheaths feature a maximum use temperature of 1200°C (2192°F).

Higher temperature applications typically rely on Syalon 050 or Syalon 110 thermocouple protection sheaths, with improved maximum use temperature capability and similar levels of physical stability. Syalon 050 is an advanced sialon ceramic that was designed to resist multiple abrasive and corrosive factors, with a hardness rating of 94 HRA and a maximum use temperature of 1450°C (2642°F). Thermocouple protection sheaths made from Syalon 050 are realistically usable at continuous temperatures of roughly 1400°C (2552°F).

Syalon 110 thermocouple protection sheaths can provide continuous use temperatures in excess of 1450°C, albeit with a reduced thermal shock resistance over Syalon 101 ceramics.

Need Help Selecting Thermocouple Protection Materials?

International Syalons is a leading supplier of refractory ceramics for demanding industrial applications. Our sialon grades are suitable for manufacturing numerous high-temperature components and imbuing them with outstanding thermal efficiency.

We provide sialon thermocouple protection sheaths in a range of standard dimensions, with lengths from 600 – 2000 mm. If you are currently going through the thermocouple sheath material selection process, or are looking for an alternative method to protecting your temperature sensors, we can help. Our sialons protection tubes offer added value compared with metal-sheathed thermocouples and other thermocouple ceramic sheath materials. Get in touch with a member of our team if you would like to learn more.