Sialons are a unique class of ceramic materials derived from silicon nitride. They are refractories comprising the main alloying elements silicon–aluminum—oxynitride, which have been sintered with an additional oxide stabilizing agent, such as yttria. This yields a high-density ceramic that is isostructural with either alpha (α) or beta (β) forms of high-strength silicon nitride (Si3N4). These established refractories exhibit outstanding tensile strength, thus degrees of physical stability under extreme thermodynamic stress. Composite grades of Si3N4 have been developed to elevate these properties with unique characteristics such as electro-discharge formability and improved resistance to corrosion.

Syalon 110 is a composite form of Si3N4 that was developed specifically for continuous steel casting applications. It performs exceptionally well with a variety of molten metals, including alloy steel, mild steel, high carbon steel, and other alloys with high iron content. Essentially, Syalon 110 excels where conventional materials display gradual wear to metal spalling, abrasion, and heat warping.

This article will explore the use of Si3N4 for ferrous metal applications, with a focus on the characteristics and benefits of Syalon 110:

Properties of Syalon 110

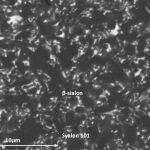

Syalon 110 is a composite ceramic of β-phase Si3N4 with boron nitride (BN) to improve the ceramic’s mechanical and chemical resistance to attack by molten ferrous metals such as steel, and the accumulation of dross or slag metal. It features an exceptional thermal shock resistance of ΔT = 800 °C, and material-leading continuous use temperatures of 1450°C (2642°F), which exceeds the average steel casting temperatures of 1200°C (2192°F).

The Difficulties of Steel Forming

Continuous casting of steels involves extruding molten metal into solidified ingots, slabs, or strips using high throughput machinery. The extrusion output component of a continuous caster varies depending upon the geometric requirements of the cast product, but cylindrical slabs of steel for profiling or rolling are typically formed using a break ring.

Break rings must exhibit outstanding resistance to the dramatically varying thermal gradients of the application, with steep differences between the internal temperature of the machinery and the ambient temperature beyond the output. They must also be composed of materials that are resistant to chemical attack from ferrous metal, otherwise the components can succumb to steel corrosion, which can result in premature device failure.

Syalon 110 overcame this issue by stabilizing the ferrous-sensitivity of Si3N4 with a boron nitride coating, which is often the material of choice for continuous steel casting applications due to its supreme resistance to steel corrosion. This proprietary arrangement enables Syalon 110 to resist chemical attack by heated steel despite the increased surface porosity of the material.

Si3N4 Solutions with International Syalons

International Syalons has demonstrable experience of providing unique material solutions for a broad range of industries. We are continuing to expand the capacities of Si3N4 formulations to offer mechanically-stable and cost-effective alternatives to conventional industry materials.

If you would like any more information about our Syalon 110 grade, or any other Si3N4 compositions, please do not hesitate to contact us.