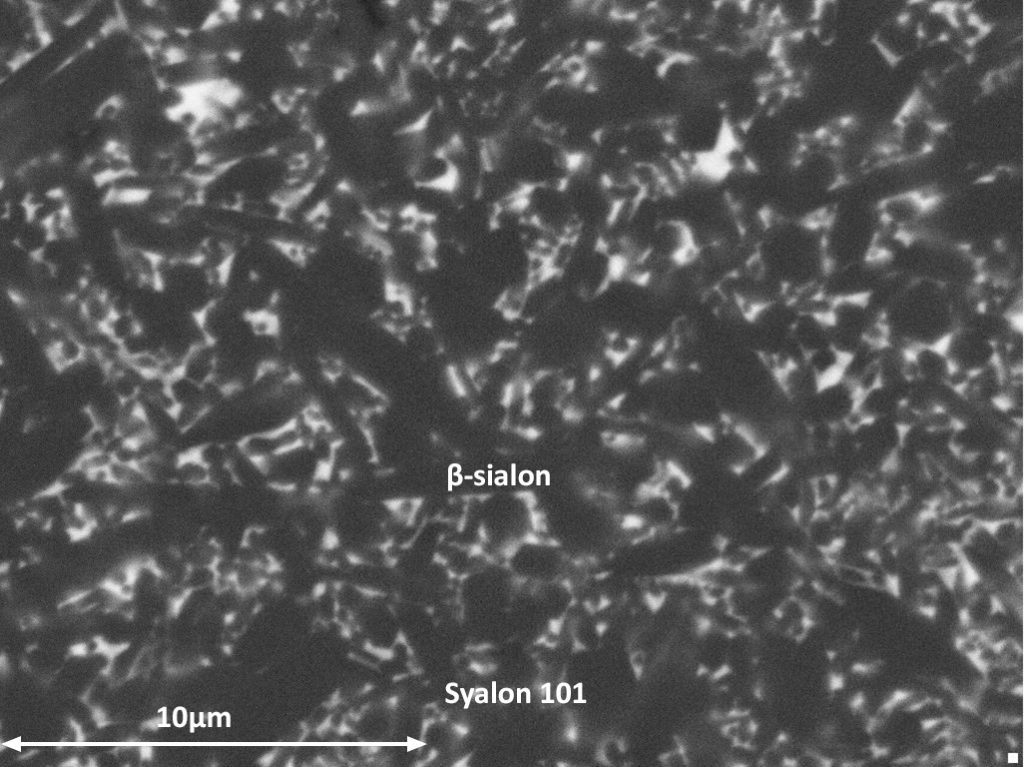

Syalon 101 is a Si-Al-O-N ceramic material with a similar crystallographic structure to beta-phase silicon nitride (β-Si3N4) which is also engineered for its extraordinary strength, toughness, and hardness characteristics. First envisaged as a cost-effective alternative to conventional silicon nitride, Syalon 101 can now compete with a broad range of established engineering ceramic materials.

This blog post will compare the mechanical and chemical properties of Syalon 101 to a range of alternative types of ceramic materials.

Exploring the Properties of Syalon Ceramic Materials

Physical Properties of Syalon 101

β-phase silicon nitride ceramic materials are renowned for their compression strength, which refers to a material’s resistance to compressive loads. This is typically quantified as a measure of the maximum uniaxial compressive strain the material can withstand before mechanical failure.

Syalon 101 boasts a nominal compression strength of up to 3500 megapascals (MPa), the joint highest value for an engineered ceramic product available from International Syalons. Sycarb 10, an advanced silicon carbide (SiC) ceramic material, features an ultimate compression strength of 3500 MPa but is inferior to Syalon 101 in terms of its modulus of rupture (MoR).

The modulus of rupture refers to the maximum level of tensile force a surface can withstand before it breaks due to bending. Zircalon 5, a zirconium dioxide (ZrO2) product, exceeds Syalon 101 in terms of its modulus of rupture by a factor of just 55 MPa. However, Syalon 101 is more resistant to compression by a factor of almost two-to-one.

Click here for a detailed advanced ceramic property comparison

Syalon 101 is even stronger than alumina (Al2O3), the most widely used ceramic material worldwide. This silicon nitride ceramic is significantly more resistant to both compression and bending, with an improved modulus of rupture at both ambient and elevated temperatures.

Thermal Properties of Syalon 101

Syalon 101 also represents outstanding thermal integrity in the presence of sustained high temperatures and abrupt thermal fluctuations. It is more resistant to thermal shock than any other advanced ceramic material available from International Syalons, withstanding mechanical failure at temperature changes as great as ΔT 900°C. This is succeeded by the rest of the silicon nitride family of materials with thermal shock resistances ranging from ΔT 400 – 800°C. Sycarb 20 and Zircalon 20, by contrast, may fail catastrophically when subjected to thermal shock gradients exceeding ΔT 350°C.

This characteristic is intrinsically linked to the thermal expansion coefficient of ceramic materials, which determines how the size of a component changes in relation to temperature variations. It is quantified in terms of the severity of material size changes in degrees across a linear or volumetric plane. Once again, Syalon 101 exceeds both silicon carbide, zirconia, and alumina in terms of reduced temperature-dependent size changes with a coefficient of thermal expansion of 3.0 x 10-6/K-1.

Syalon 101 Compared to Other β-Silicon Nitrides

Advanced ceramic engineering changed significantly when silicon nitride was first discovered. It was then possible to produce an advanced silicon nitride-based ceramic material at significantly reduced manufacturing costs and capabilities. Syalon 101 was the first of these β-phase silicon nitrides, and it remains one of the most popular advanced ceramics currently manufactured.

It still succeeds alternative β-silicon nitride ceramic materials in terms of strength, although specialized products have been engineered for enhanced mechanical integrity at higher peak temperatures. If you would like any more information about the thermal or mechanical properties of our advanced ceramic materials, please do not hesitate to contact us.