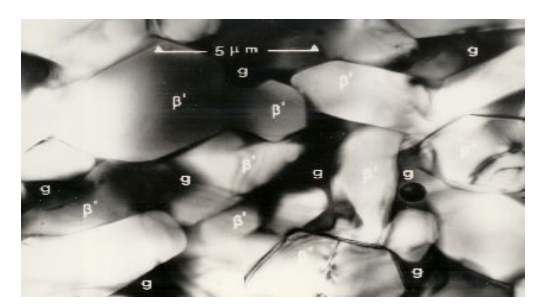

At International Syalons, we have explored the mechanical properties of silicon nitride (Si3N4) at great length. Silicon nitride is an advanced engineering ceramic that circumvents many of the conventional drawbacks of numerous oxide ceramics. Outstanding fracture toughness and high moduli of both rupture and elasticity impart excellent resistance to multiple wearing phenomena. This enables silicon nitride-based ceramics to withstand severe operating conditions that may cause comparatively brittle ceramics to propagate flaws, deform, or fail.

These properties are largely functions of either strength or toughness, which respectively determine the mechanical integrity of a material in response to loading or bending forces. Hardness is another key factor in the mechanical behavior of technical ceramics.

This blog post will explore the hardness of silicon nitride-based ceramics and why it is a critical property for engineering applications.

Explaining Hardness

The hardness of a material is a measure of how well its crystalline structure holds together in response to friction or impact forces. Hardness usually exhibits a linear relationship to the strength of the intermolecular atomic structure of the material. However, it is a complex property that is dependent on numerous factors including strength, toughness, and ductility.

Three distinct measurement types are ascribed to determine the hardness of materials in response to specific forms of stress. In engineering sectors, the most prevalent form of testing is for indentation hardness. This refers to a material’s ability to resist deformation by an indenter such as a sharp point. Indentation hardness can be further broken down into multiple scales determined by different testing methodologies.

Silicon nitride’s hardness characteristics are typically tested using the Vickers or Rockwell scales, otherwise known as the microhardness method. A diamond pyramid indenter is pressed into the surface area of the test material at a known load force. The level of indentation is then measured and converted into a unit of hardness, which is expressed as the load over the indentation’s surface area (Kg/mm2 or GPa).

The Importance of Hardness

Extreme hardness values enable ceramics to withstand significant wearing phenomena from mechanical agitation to small-particle abrasion. This enables silicon nitride-based ceramics to be engineered into complex, long-lasting shapes for rugged application in some of the most demanding industrial sectors on earth. Nozzles, plates, milling media, welding jigs, and fixtures are all routinely manufactured using silicon nitride-based ceramics.

International Syalons provides a comprehensive range of silicon nitride and sialon under the Syalon product family. These exhibit distinct hardness characteristics suitable for varying applications.

- Syalon 050: hardness value of 19.81 GPa.

- Syalon 101: hardness value of 14.71 GPa

- Syalon 110: hardness value of 11.77 GPa

- Syalon 501: hardness value of 13.24 GPa

Silicon Nitride Ceramics from International Syalons

International Syalons specializes in manufacturing high-performance ceramics with uniquely tailored thermodynamic properties suitable for demanding applications. Our Syalon product range covers all three crystalline phases of silicon nitride, and is available with hardness properties exceeding that of refractory alumina.

If you would like any more information about the mechanical properties of silicon nitride, read our previous posts:

Otherwise, contact us directly with any questions.