The 20th Century was an era of rapid innovation in ballistics technology, and subsequently in how conflicts were conducted. Military organisations worldwide opted to improve the manouverability of troops and vehicles without compromising the performance of protective equipment in response to high velocity impacts. This led to the gradual adoption of novel ceramic materials in defence applications.

Advanced ceramic materials have formed the backbone of modern armour panelling and body armour systems since the high strength and lightweight performance of boron carbide (B4C) was first exhibited in the Vietnam conflict. Armoured seating provided additional levels of protection for personnel and pilots in combat scenarios, yet these armour systems can be considered rudimentary by today’s standards.

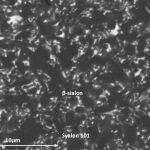

State-of-the-art materials such as silicon nitride (Si3N4), alumina (Al2O3) and silicon carbide (SiC) based advanced ceramics have been employed as ballistic-resistant exterior tiling for helicopters, planes, and drones. They have also largely replaced metal-based armour plating for body armour and have increasingly been used in tank and APV construction. Significant strides have also been made in utilising advanced ceramic materials for missile radomes, supporting lighter weight projectiles with more precise targeting capabilities than ever before.

Ceramic Materials for Armour Systems & Missile Radomes

A ceramic armour plate is a composite system that absorbs an impact by shattering hard projectiles and capturing the fragments, distributing the kinetic energy across the plate. This limits the severity of penetration and reduces the extent of injury sustained by personnel or damage done to vehicles. The mechanics of ballistic impacts and penetration resistivity are extremely complex, and ballistic testing must be carried out on a holistic basis to determine how ceramic materials respond to bullets of different calibres that are fired at varying velocities. It is also important to determine how multiple hits affect the performance of the plate, and the resistance of the material to projectiles of different compositions and designs.

In theory, hardness and toughness are two of the primary properties to consider when constructing armour systems from ceramic materials. Fracture strength should also be considered, yet there is no individual consensus as to which property is paramount in terms of ballistic performance.

Impact characteristics is less critical a metric of success for components such as missile radomes. These protective caps or plates are attached to the front or body of a missile to improve the aerodynamic behaviour and protect internal electronics. This mandates a material with good electromagnetic transparency and high degrees of formability. Advanced ceramic materials are often used in the fabrication of missile radomes given the range of existing near-net shape fabrication techniques available for the likes of silicon nitride. Different profile cones and shapes can be engineered to suit missiles of varying payloads and targeting capabilities. The outstanding thermomechanical properties of advanced ceramics allow the latest generations of missile to travel at greater velocities, and therefore longer ranges and with increased accuracy.

Ceramic Materials from International Syalons

International Syalons is the UK’s leading authority in advanced ceramic materials for industrial applications. Our product range includes hard wearing alumina and extreme hardness silicon carbide, each of which is suitable for use in the defence sector.

If you would like any more information about using ceramic materials for defence and aerospace applications, please do not hesitate to contact us.