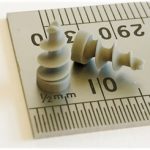

Advanced ceramics manufacturing comprises three essential stages: raw powder processing; forming; and sintering. This generally describes the process of consolidating a powder-based feedstock and firing the green body to achieve a fully-densified technical ceramic. Net shapes with comparatively loose dimensional tolerances (~1-3%) can typically be produced ‘as-sintered’; requiring no machining or finishing prior to quality assurance inspections. Components with tight tolerances cannot be produced ‘as-sintered’ and may require diamond grinding to ensure that the net shape is usable according to the design intent.

So, how do you grind ceramics to achieve the optimal surface texture and finish?

What is Diamond Grinding?

Diamond grinding is an advanced finishing technique used to improve the surface finish and tighten the dimensional tolerances of hard-wearing technical ceramics. Alumina (Al2O3), sintered silicon carbide (S-SiC), zirconia (ZrO2), silicon nitride (Si3N4), and sialon (SiAlON) are among the hardest manufactured bulk materials on the planet. Removing material from the component surface, to eliminate flaws and correct dimensional variations after sintering, is subsequently impossible for conventional tooling.

Diamond grinding exploits the inherent high hardness and strength of diamond to precisely remove material from the surface of a high-hardness technical ceramic. This is typically conducted using a combination of the following processes:

- Grinding;

- Cutting;

- Honing;

- Lapping;

- Polishing

Typically, diamond grinding is conducted using a cold-pressed metal wheel with welded or resin-bonded diamond fragments, which vary in size and design depending upon the workload and component dimensions. Diamond grinding is typically conducted at a very slow rate of as little as 1 micron per pass of the wheel. This is to preserve the mechanical properties of the ceramic while only altering the geometry of its uppermost surface layers.

Cutting is another form of diamond grinding that typically utilises a specialised tool such as a fixed diamond wire, saw or wheel. This technique can dramatically alter the end-product’s mechanical qualities, limiting both yield and tensile strength if not carried out with very high precision. It is useful in the fabrication of electronics substrates and smaller components.

Finally, lapping and polishing is a unique form of diamond grinding that utilises an abrasive slurry and high-strength polishing pads. Diamond particles in the polishing solution are rubbed against the ceramic to level its surface and eliminate topographical variations formed during the grinding process.

Diamond Grinding with International Syalons

International Syalons is the UK’s leading supplier of silicon nitride and sialon-based technical ceramics. We offer a broad range of products and services, including expert manufacturing support and advice. It is always best to work towards as-sintered tolerances with advanced technical ceramics as diamond grinding can be costly and time-consuming.

We have extensive experience developing technical ceramics for complex end-product applications, from small tailored shapes to larger engineering components. If you would like more information about developing as-sintered ceramics or optimizing your diamond grinding processes for improved throughput and product yield, simply contact us directly.