Additive manufacturing (AM) of ceramics, also known as ceramic 3D printing, is an attractive engineering solution for challenging applications. Technical ceramics, like silicon nitride (Si3N4), largely outperform industrial-grade polymers and metals for high-temperature operations, with superior mechanical properties and thermodynamic stability. Yet these same properties make ceramics difficult to use as a feedstock in additive manufacturing processes.

And yet, AM ceramic solutions are clearly advantageous for many critical business and engineering objectives. Precision ceramic components can be used to great effect in industries as varied as aerospace and defence, automotive engineering, chemicals and petrochemicals manufacturing, energy generation, molten metal handling, and more.

Why Ceramic 3D Printing is Such an Attractive Solution

Modern industrial demands are constantly underpinned by a need to improve sustainability and throughput while driving down costs. This can often be achieved by replacing essential, perishable components with longer-serving materials like advanced ceramics. Yet the limitations of conventional ceramic manufacturing make it difficult to meet the increasingly stringent demands of highly-toleranced custom components with complex geometries. For example; the latest generation of silicon nitride based ceramic aerospace components are vital for the aerospace industry to improve fuel efficiency and are already commercially attractive, yet still pose significant technical challenges.

Additive manufacturing is often touted as the answer to this issue, although historically it has been difficult to produce ceramic components via lithographic AM technology with equal performance levels characteristic of conventionally produced material.

R&D Into Additive Manufactured Ceramic Solutions

Significant research and development into additive manufacturing technologies has yielded incredible results in recent years. Commercial 3D printers are now available at large scales while medical and life sciences sectors have successfully printed organic tissues via additive manufacturing.

The commercial benefits of using lithographic AM to produce advanced ceramic solutions are self-evident. It demonstrates a previously impossible level of geometric freedom for technical ceramics, with exceptional levels of form and topographical accuracy. Yet, of the countless technologies that have been explored, few have demonstrated the required real-world applicability nor the critical microstructural behaviour of the end-product.

International Syalons has invested heavily into additive manufacturing of ceramic solutions, particularly silicon nitride and sialon, to assist in the development of commercially-viable technologies capable of generating complex ceramic shapes. Using a proprietary 3D printing technique, we can now produce bespoke components with extremely intricate geometries. This is not the first tool used to successfully print technical ceramic solutions, yet it is one of the first to achieve near-identical end-product characteristics to the parent material.

Read our Introduction to Additive Manufacturing for Silicon Nitride Ceramics

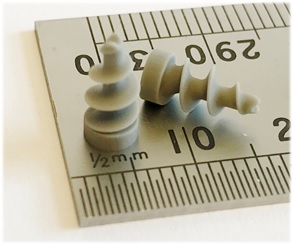

The benefits of additive manufacturing ceramic solutions for the application areas listed above is currently marginal, with standard iso-static processing still considered the benchmark for generating high quality components with real-world usability. However, International Syalons’ L-AMT silicon nitride is a proof of concept material that is broadly suited to generating unique, prototypical components that can supplement additional materials. The eventual areas of application are myriad, from engine design, electronics manufacturing, medical and dental implants, and much more.

Ceramic Solutions from International Syalons

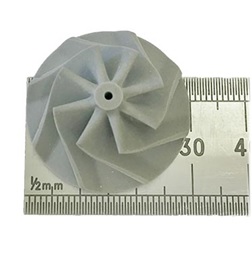

International Syalons is the UK’s foremost supplier of ceramic solutions for industrial areas of application. We have successfully utilised lithographic additive manufacturing to generate bespoke components, such as extremely small-scale silicon nitride impellers. These ceramic solutions exhibit outstanding mechanical properties that surpass alternative 3D printing methods currently used to generate ceramic shapes.

If you would like to learn more about the latest developments in 3D printing of ceramics, simply contact a member of the team today.