There are a plethora of applications worldwide that benefit from using technical ceramics because of their high strength, thermal stability, and other unique advanced properties, and industrial processing is no exception. Ceramics play an important role in cutting tools, high-temperature furnace components, and high-wear applications, as they can withstand harsh environments. One ceramic material with very interesting properties is alpha-sialon. Sialons were developed as a cost-effective alternative to silicon nitride and are more often found in three useable phases, one of them being alpha-sialon. This post will provide an overview of alpha-sialon’s structure, primary applications, and benefits.

What is the Structure of Alpha-Sialon?

Alpha-sialon (α-sialon) is a complex material iso-structural to silicon nitride (Si3N4) and is synthesised with a combination of aluminium, nitrogen, oxygen, and silicon. It has a hexagonal crystal structure and comprises small, equiaxed grains that result in the high hardness of the material. Unlike the beta-sialon structure, which has long ‘channels’ through it, the channels are blocked at various stages, creating multiple interstitial holes. The interstitial holes enable elements such as calcium (Ca), lithium (Li), and yttrium (Y) into its structure, which helps to enhance the properties of Alpha-sialon.

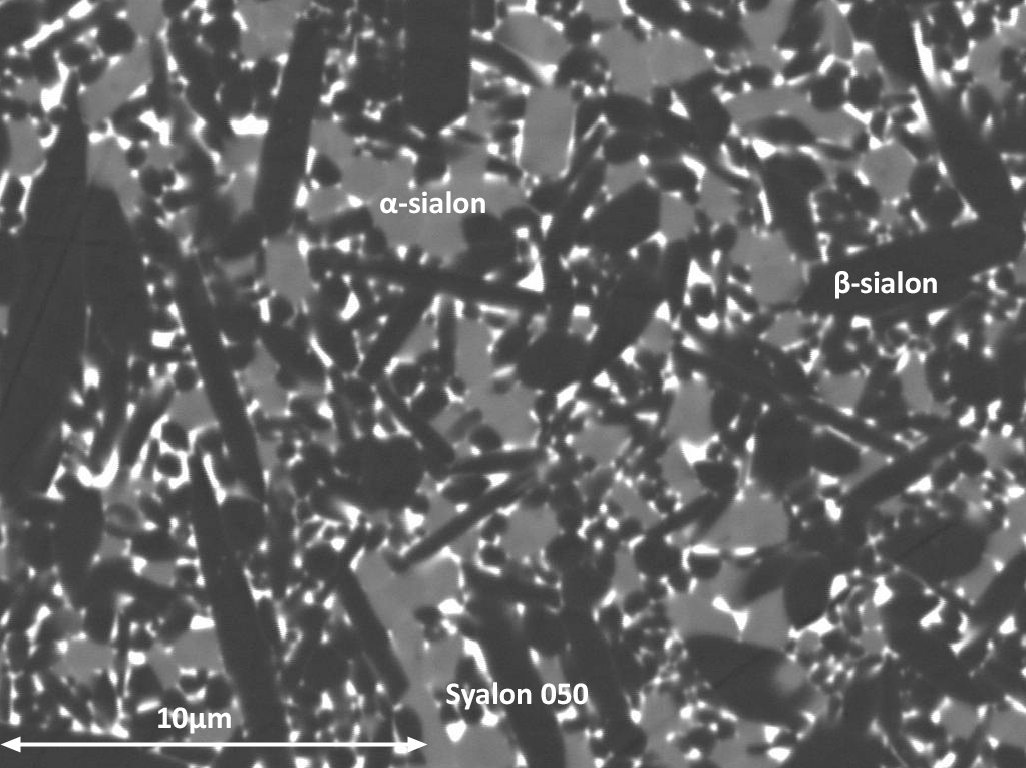

SEM micrograph showing the microstructure of Syalon 050. The needle-like beta-sialon and equiaxed alpha-sialon grains surround small pockets of glassy phase. Image Credit: International Syalons (Newcastle) Ltd.

Applications of Alpha-Sialon

The structure of alpha-sialon supports its outstanding properties and makes it suitable for various industrial applications. In industrial processing, alpha-sialon is used in cutting tools, furnace components, and wear-resistant consumables. It is also widely used for various components in the automotive, healthcare, and telecommunications industries.

Cutting Tools

Many small components for machining equipment are manufactured with alpha-sialon, especially for those used in drilling, milling, and turning. Alpha-sialon is known for its high hardness and strength, which are critical in high-pressure and high-temperature operations.

Furnace Components

Alpha-sialon has high-temperature stability, making it an ideal solution for furnace components. As furnaces reach incredibly high temperatures and operate under high pressure, it’s crucial that the components can withstand these conditions.

Wear-Resistant Consumables

Wear-resistant consumables are required for industrial components such as dies, nozzles, valves, and more. Alpha-sialon is the perfect material for these pieces because of its excellent mechanical properties and high wear resistance. As a result, machinery can run more efficiently with greatly reduced maintenance time and overall consumable costs.

The Benefits of Alpha-Sialon

Alpha-sialon offers multiple benefits over traditional materials in industrial processing and other industries. Not only was it designed as a more cost-effective material than silicon nitride, but its structure gives way to several unique properties, including the following:

- Excellent Shock and Wear Resistance

- High Hardness

- High Strength

- Strong Fracture Toughness

- Outstanding Thermal Stability

When combined, all of these properties of alpha-sialon open doors to many applications. Knowing that a high-strength material can withstand high pressure and temperatures ensures operational safety, longevity, and production success, contributing to business growth.

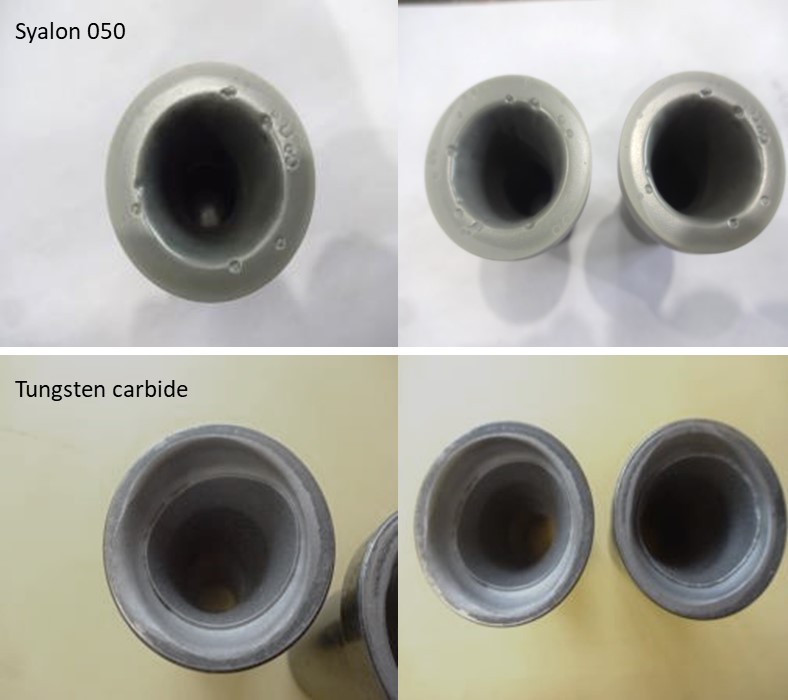

Sialon 050 vs Tungsten Carbide nozzles. Image Credit: International Syalons (Newcastle) Ltd.

In Need of Alpha-Sialon?

If your applications could benefit from Alpha-sialon and its outstanding properties, International Syalons are leading experts in advanced ceramics. For over 40 years, we have been developing a vast range of sialon and silicon nitride-based ceramic products and powders used worldwide in many industries.

Get in touch with a team member today to learn more about how Alpha-sialon could enhance your applications.