Engineers increasingly turn to technical ceramics for demanding applications where traditional materials fall short. These materials offer an outstanding combination of high hardness, superior wear resistance, and robust thermal stability, maintaining their integrity under extreme temperatures and corrosive environments. Whether for aerospace components, cutting tools, or molten metal components, their unique properties make them indispensable. Their low mass compared to metals further enhances performance by providing strength without excessive weight, making them an ideal choice for advanced engineering solutions.

This impressive combination of properties doesn’t come easily. It requires a meticulous multi-step workflow. Let’s explore how technical ceramics are made, step-by-step.

1. Raw Material Preparation

Manufacturing high-quality ceramic products begins with selecting the right raw materials. In advanced ceramics, materials such as silicon nitride are typically sourced in powder form. Achieving a uniform final product hinges on the purity and consistent particle size of these powders. The raw materials often undergo milling processes to reach the desired particle size and distribution. This step is crucial as it directly impacts the effectiveness of subsequent forming and sintering processes.

2. Forming Techniques

The forming stage is where the ceramic material begins to take shape. Several techniques are employed depending on the desired characteristics of the final product:

- Uniaxial Pressing: This method involves compressing the ceramic powder in a die under high pressure. It’s suitable for producing simple, symmetrical shapes. However, the density of the pressed product can vary, requiring careful control during the process.

- Isostatic Pressing: This technique applies uniform pressure from all directions, resulting in a more homogenous density distribution. It’s ideal for green machining complex shapes and ensuring uniformity across the component.

- Slip Casting: Slip casting is preferred for simple and often hollow shapes. In this method, a slurry of ceramic powder and liquid is poured into a mold. The liquid is then removed, leaving a solidified ceramic body. This technique allows for the production of complex geometries with fine details.

- Extrusion: Extrusion is the go-to method when long, continuous shapes are needed. The ceramic powder is mixed with a binder to form a pliable mass that can be forced through a die to create elongated shapes, such as tubes or rods.

3. Sintering

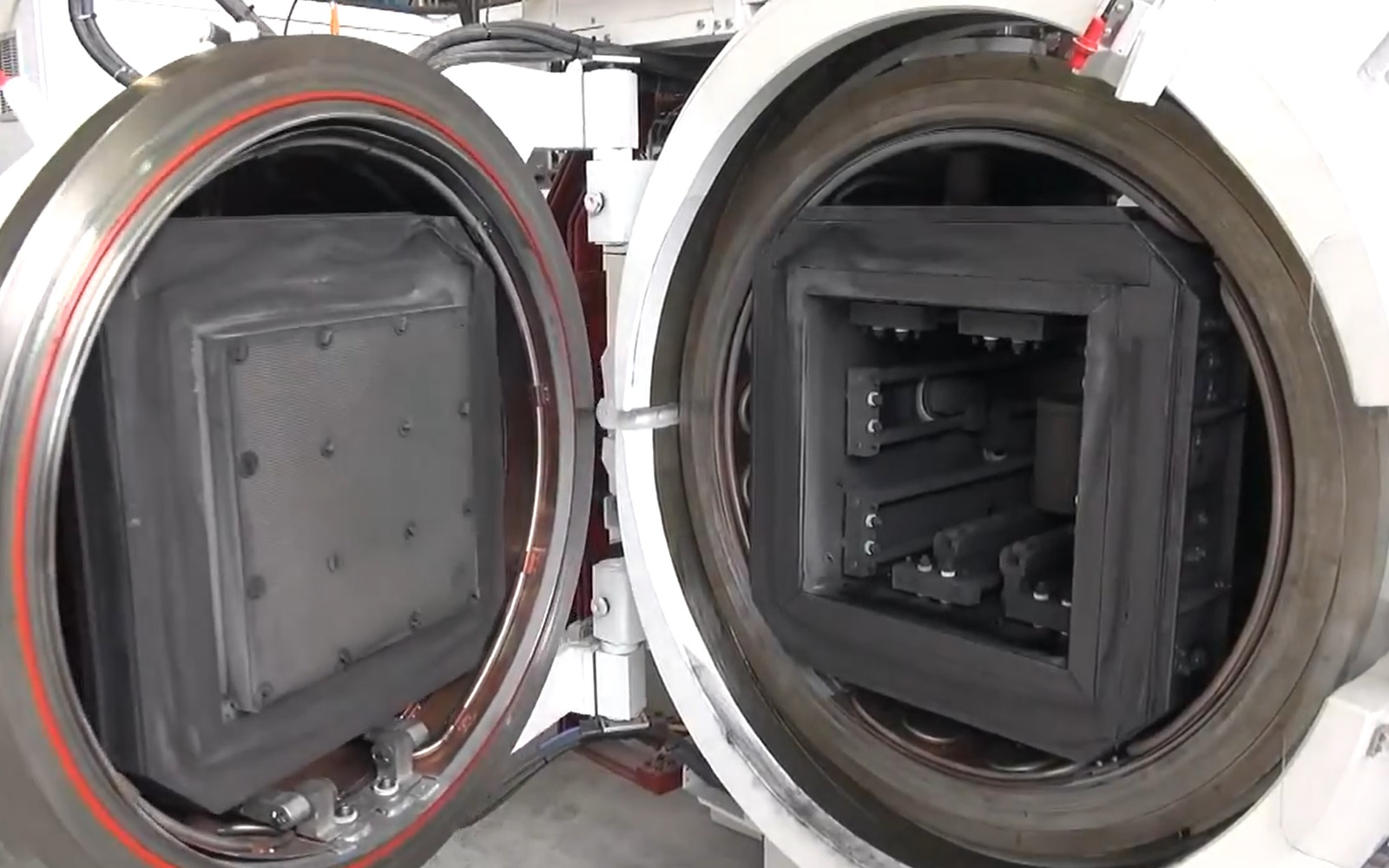

Sintering is a critical step that transforms the shaped ceramic from a porous form into a dense, solid structure. During sintering, the ceramic body is heated to a temperature below its melting point, causing the particles to bond together. This process eliminates porosity, enhances the material’s strength, and solidifies its shape.

For materials like silicon nitride, sintering typically occurs in a controlled atmosphere to prevent oxidation and maintain the material’s integrity. Additives may also be used to promote densification and reduce the sintering temperature, ensuring the material retains its desired properties.

Silicon nitride sintering furnace. Image Credit: International Syalons (Newcastle) Ltd.

4. Diamond Grinding

Post-sintering, the ceramic product may require grinding to achieve the final dimensions and surface finish. Due to the extreme hardness of ceramics, traditional machining techniques are generally ineffective. A more intensive method like diamond grinding must, therefore, be employed. This process uses diamond-tipped tools to precisely grind the ceramic, ensuring tight tolerances and a smooth finish. Diamond grinding is particularly important in applications where the ceramic component must interact with other parts, requiring high precision and surface quality.

5. Inspection and Quality Control

The final step in the manufacturing process is inspection and quality control. Advanced ceramics must meet stringent specifications to ensure they perform as expected in demanding environments. Non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are often used to detect internal defects or inconsistencies. Dimensional inspections ensure the component meets required tolerances, and surface finish inspections confirm the absence of defects that could compromise the material’s performance.

Advanced ceramic weld location pins. Image Credit: International Syalons (Newcastle) Ltd.

Additive Manufacturing of Ceramics

In recent years, additive manufacturing (AM), commonly known as 3D printing, has emerged as an innovative technique for producing advanced ceramics. This method allows for complex geometries that are difficult or impossible to achieve with traditional methods. AM offers significant geometric freedom, enabling the production of intricate shapes with high precision. However, achieving the same material properties as conventionally manufactured ceramics remains a challenge, particularly in terms of density and mechanical strength.

International Syalons has embraced this cutting-edge technology to complement our traditional manufacturing processes. By integrating additive manufacturing with established techniques like sintering and diamond grinding, we can produce custom technical ceramics that meet specific application requirements. This hybrid approach allows for the rapid prototyping of new designs, which can then be refined and scaled up for full production. It also enables the creation of bespoke components tailored to the unique needs of industries like aerospace, electronics, and energy.

Why Choose International Syalons?

International Syalons is at the forefront of advanced ceramic manufacturing, with over four decades of expertise in producing high-performance ceramics. Our state-of-the-art facilities are equipped to handle the stringent manufacturing conditions necessary for producing silicon nitride, sialons, and other technical ceramics. We specialize in custom solutions tailored to the specific needs of our clients, ensuring that every component meets exacting standards for performance and durability.

Learn more about the manufacturing process of ceramics with our articles and guides

Whether your application involves extreme temperatures, corrosive environments, or high wear conditions, International Syalons is prepared to deliver custom-made ceramics that excel in the toughest conditions. With a commitment to innovation and collaboration with leading research institutes, we continue to push the boundaries of what’s possible in ceramic technology.

Contact us to learn more about our capabilities or to request a consultation. Let us help you find the perfect solution for your industrial challenges.