Drawing metal wire through dies generates intense friction as coating and extruding cable exposes tools to high heat. These tough conditions challenge wire and cable manufacturers, who must optimise for efficiency without sacrificing equipment durability. Sialons, a specialized class of technical ceramics derived from silicon nitride, provide a solution. Their remarkable resistance to wear, heat, and corrosion helps extend tool life, boosting performance and reducing downtime across production lines.

High Friction and Wear

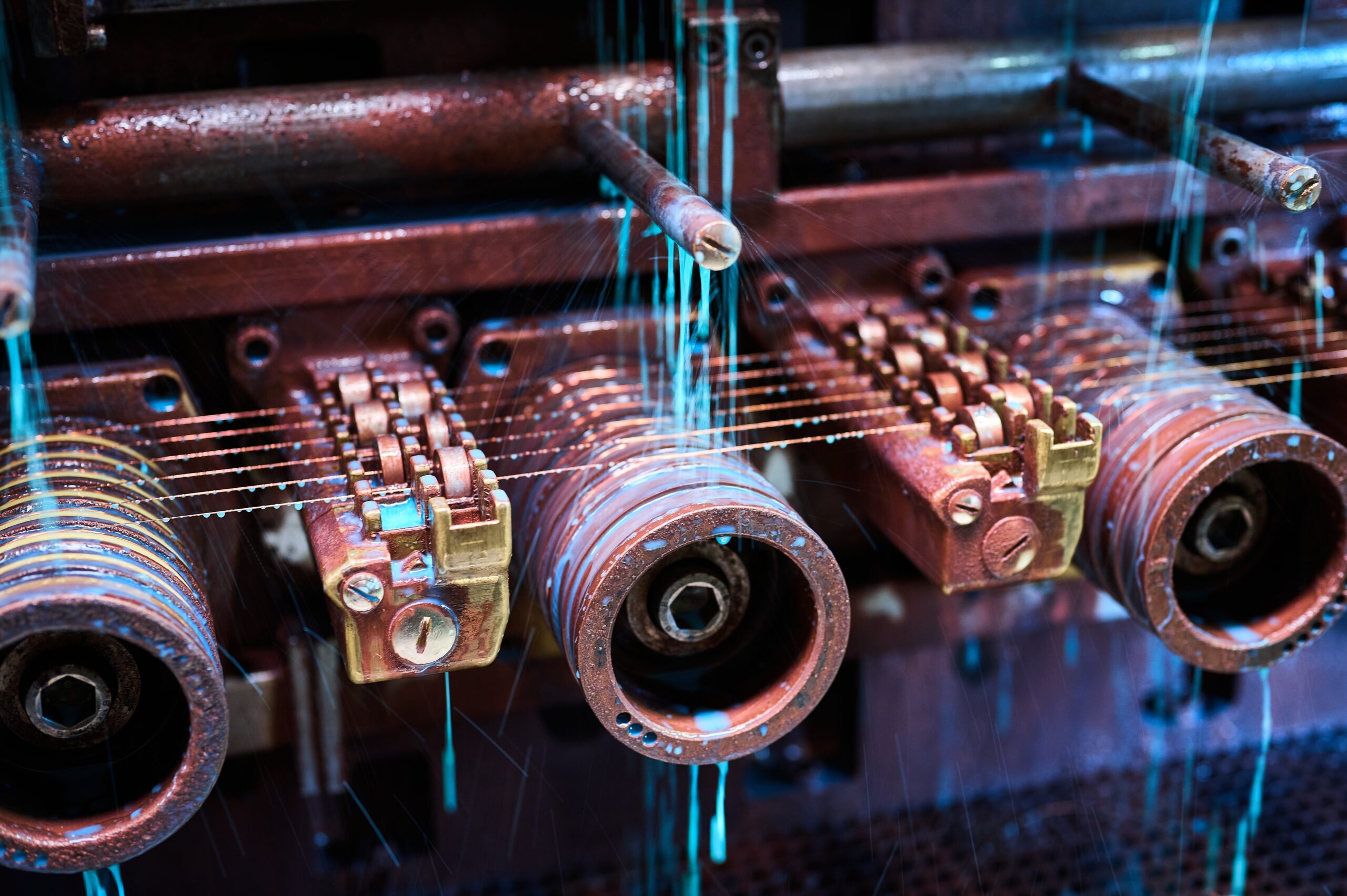

Wire drawing is a fundamental step in cable production. It involves drawing metal through dies at high speeds and tension, generating significant friction. This leads to wear on critical parts, including drawing dies, rollers, and guides. Over time, this wear reduces production efficiency by increasing maintenance needs and the risk of defects on the wire surface.

Sialons can help due to their low coefficient of friction; a result of their high toughness and wear resistance. Using sialons to manufacture drawing dies and rollers results in significantly reduced wear phenomena, extending component service life. This not only lowers maintenance costs but also minimizes production downtime, ensuring consistent, high-quality wire output. By adopting Sialon-based components, manufacturers can cut costs associated with frequent replacements, making their processes more cost-effective and reliable.

Copper wire drawing. Image Credit: Shutterstock

Heat Resistance

The wire manufacturing process, particularly with metals like copper and aluminium, generates immense heat due to both the friction involved and the electrical conductivity of the materials. High temperatures can deform metal tools, cause inaccuracies in wire dimensions, and even damage delicate wire coatings. Such heat also accelerates wear on traditional metal components.

Sialons exhibit excellent thermal stability, capable of withstanding extreme temperatures without deforming or losing their mechanical properties. Unlike metals, Sialons resist both thermal expansion and shock, ensuring that tools retain their shape and functionality, even in high-temperature environments. This makes Sialons perfect for applications like wire drawing, where equipment is subjected to continuous heat and mechanical stress. Their ability to maintain performance under these conditions helps manufacturers maintain tighter tolerances, preventing defects and ensuring high precision throughout the process.

Corrosion Resistance

In some cable manufacturing environments, particularly those involving chemical processing or harsh environmental conditions, equipment components face the added threat of corrosion. Traditional metal parts, even those made of stainless steel, are vulnerable to chemical reactions that can degrade their surface, leading to contamination of the wire and premature failure of the tools.

Sialons are chemically inert, making them resistant to corrosion from most acids, alkalis, and other aggressive chemicals used in production environments. Their ability to withstand such exposure without degradation helps maintain the cleanliness of the production process, reducing the likelihood of contamination on the wire surface.

Electrical Insulation

Wire production, particularly for high-voltage or sensitive electronic applications, requires careful management of electrical conductivity. Traditional metal tools can introduce unwanted electrical interference or cause short circuits, which is especially problematic in applications like medical devices or aerospace.

As non-conductive ceramics, Sialons serve as excellent electrical insulators. When used in the production of high-performance cables, they help eliminate the risk of accidental electrical discharge, which can compromise product integrity. This property is especially valuable in sectors like telecommunications, where clean, interference-free cables are essential for reliable performance. By incorporating Sialons into production equipment, manufacturers can enhance the safety and precision of their operations.

Precision and Surface Finish

High-performance wires, such as those used in aerospace or medical industries, demand precise dimensions and flawless surface finishes. Wear on drawing dies or other tools can lead to inconsistencies in wire diameter or surface defects, which can result in product failures or quality rejections.

Thanks to their hardness and durability, Sialons enable manufacturers to achieve tighter tolerances and smoother surface finishes on their wires. Sialon components maintain their precision for extended periods, reducing the need for frequent recalibrations or tool replacements. This contributes to producing wire and cable products of consistent quality, ensuring that they meet the stringent demands of critical industries.

Closing Thoughts

Incorporating Sialons into wire and cable production processes offers numerous benefits, including:

- Extended tool life due to their exceptional wear resistance.

- Improved heat resistance, allowing tools to withstand high temperatures without deformation.

- Corrosion resistance, ensuring the integrity of equipment in harsh environments.

- Electrical insulation, providing a non-conductive solution for sensitive cable applications.

- Enhanced precision, delivering smoother surfaces and better dimensional control.

At International Syalons, we are committed to delivering solutions that enhance the efficiency and reliability of wire and cable production. By integrating Sialons into your manufacturing processes, you can significantly extend the lifespan of critical components, reduce downtime, and improve product quality across various applications. Whether you’re facing challenges with wear, heat resistance, or precision, our Sialon materials offer unmatched performance to meet your needs. Explore the full benefits of Sialons, including their exceptional thermal stability, corrosion resistance, and electrical insulation properties. Discover how our advanced ceramic solutions can elevate your production line.