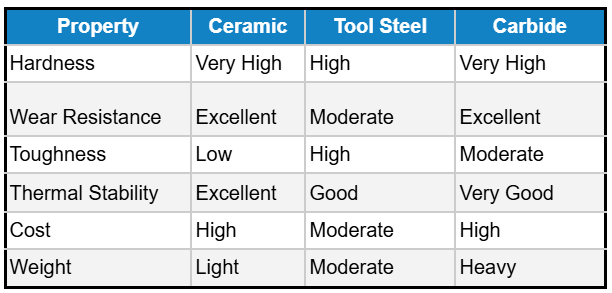

When selecting the right wire and cable guides, choosing the best material is crucial for maximizing efficiency, reducing maintenance costs, and ensuring long-lasting performance. Three common materials—ceramic, tool steel, and carbide—each offer distinct advantages and limitations in this context. Let’s compare them in detail, highlighting why ceramic materials are often the superior choice, particularly in challenging high-wear environments

Ceramic Wire and Cable Guides

Ceramic materials are renowned for their high hardness, excellent wear resistance, thermal stability, and low friction coefficients. Additionally, ceramics are chemically inert and provide electrical insulation, which can be valuable in applications sensitive to heat or electricity.

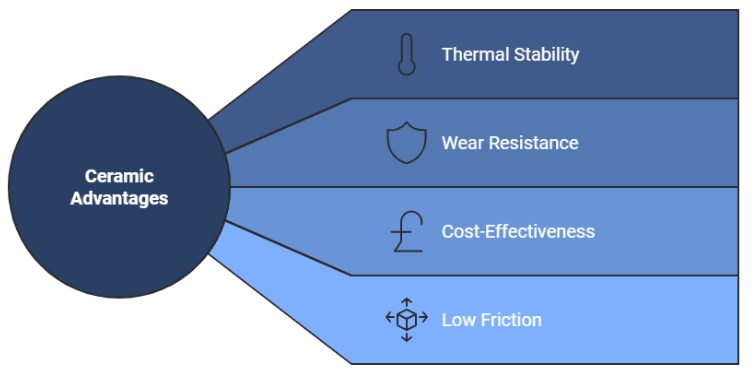

Advantages

One of the standout features of ceramic wire guides is their ability to operate under extreme temperatures. In high-speed or high-temperature wire drawing operations, ceramics maintain their structural integrity, ensuring consistent performance. This is particularly important for processes involving abrasive materials where thermal expansion or heat buildup could degrade the performance of other materials. Ceramic’s low friction coefficient minimizes heat generation during operation, which helps protect the wire from damage and extends the lifespan of the equipment.

Additionally, ceramic’s electrical insulation properties are an added benefit in applications where conducting electricity could pose a hazard or interfere with the process. For example, in the electronics industry, ceramic guides can help safeguard delicate wiring from electrical shorts and resist corrosion from exposure to reactive chemicals.

Limitations

While ceramic guides offer many advantages, they do have some limitations. Their brittleness can make them susceptible to cracking under mechanical impact, and they are generally more expensive than tool steel or carbide guides. However, their long service life often offsets the initial higher cost, especially in high-wear applications where frequent replacement of metal guides would incur significant downtime and maintenance costs.

Tool Steel Wire and Cable Guides

Tool steel is well known for its toughness, good wear resistance, and heat treatability. It offers a balance between hardness and impact resistance, making it an attractive option for environments where mechanical stresses are a concern. Tool steel is also magnetic and can be heat-treated to achieve specific mechanical properties depending on the application.

Advantages

One key advantage of tool steel is its cost-effectiveness. It is generally less expensive than ceramic or carbide materials while still providing durable performance. Tool steel is versatile, and its heat-treatability allows manufacturers to fine-tune its hardness for specific needs, making it suitable for many different wire and cable guiding processes. Another benefit is its ability to withstand impact, which makes it suitable for applications where physical forces or mechanical shock may be present. Tool steel also performs well in moderate-temperature environments, though it cannot handle extreme temperatures or high-wear conditions as effectively as ceramic or carbide.

Limitations

Despite its versatility, tool steel has lower wear resistance compared to ceramic and carbide, meaning it will need to be replaced more frequently in abrasive or high-speed environments. It also performs less efficiently in high-temperature settings, which can limit its use in industries such as aerospace or advanced electronics manufacturing where heat resistance is critical.

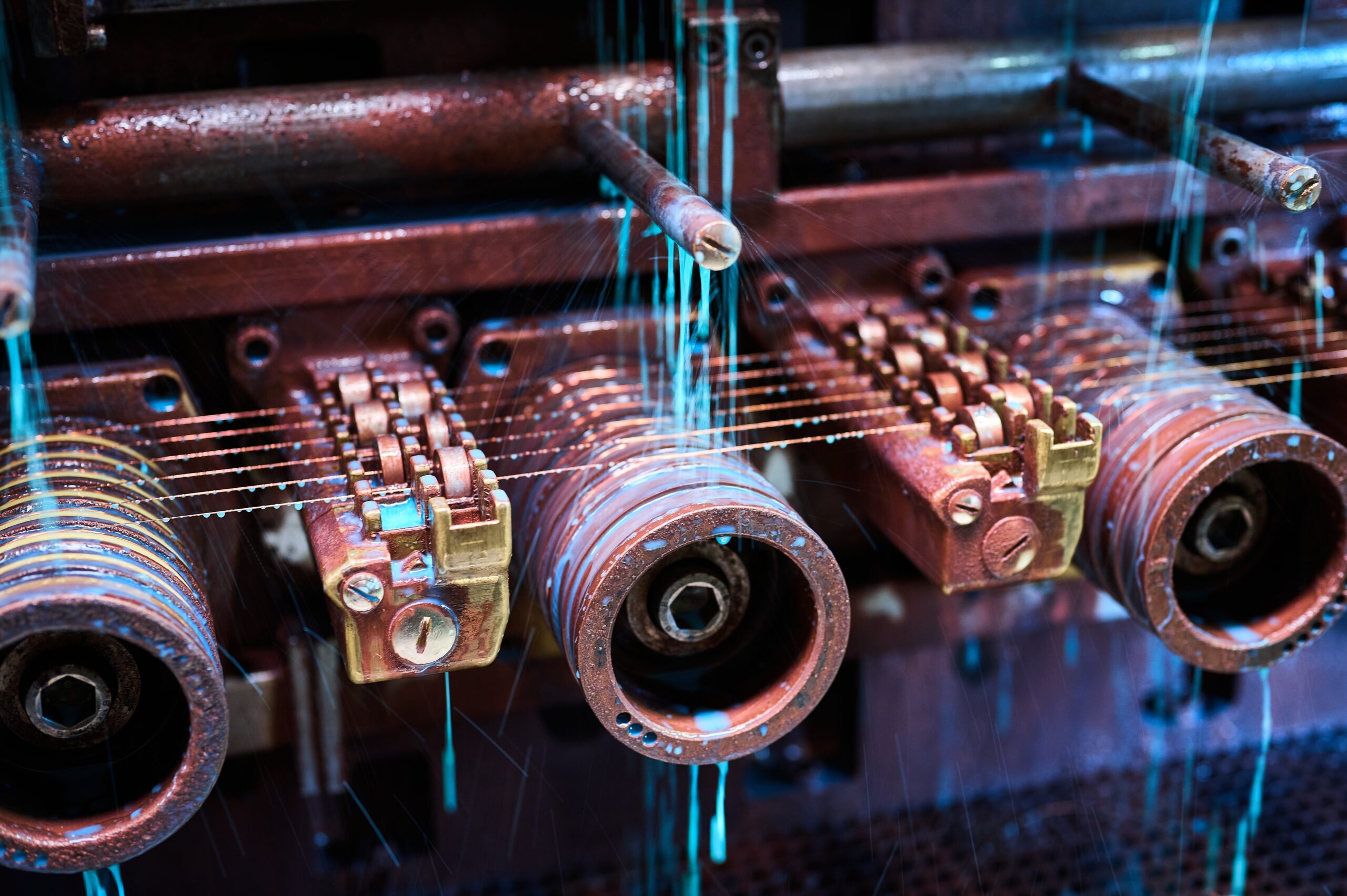

Copper wire drawing. Image Credit: Shutterstock

Carbide Wire and Cable Guides

Carbide, particularly tungsten carbide, is known for its extremely high hardness and excellent wear resistance. It also offers good thermal conductivity, making it suitable for high-temperature applications where heat dissipation is important.

Advantages

The standout benefit of carbide wire guides is their exceptional wear resistance. This makes carbide an ideal choice for applications involving high-speed wire drawing or highly abrasive materials, where minimizing tool wear is essential. Carbide also retains its hardness at elevated temperatures, making it more heat-resistant than tool steel, though not to the same degree as ceramic. Carbide’s thermal conductivity can help dissipate heat in applications where overheating could cause wire damage, contributing to longer tool life and more consistent product quality.

Limitations

Like ceramics, carbide is brittle and can chip or crack under heavy mechanical impacts. Additionally, carbide’s high density makes it significantly heavier than ceramic or tool steel, which can be a drawback in certain applications where weight is a factor. Carbide is also more expensive than tool steel, though its high durability can justify the initial cost in high-wear environments.

Comparative Analysis: Ceramic, Tool Steel, and Carbide

Why Choose Ceramic?

While tool steel and carbide each have their applications, ceramics consistently outperform them in high-temperature, high-wear settings. Ceramic guides offer unmatched thermal stability, ensuring consistent performance even in extreme temperatures. Their wear resistance means they maintain their structural integrity far longer than steel, reducing the need for frequent replacements and minimizing downtime.

In environments where wire quality and processing speed are key, ceramics’ low friction ensures smoother operations, reducing damage to the wire while maintaining the guide’s geometry over time. Although ceramics come with a higher upfront cost, their durability, wear resistance, and low maintenance requirements make them a more cost-effective solution in the long run, especially for high-speed wire drawing and abrasive materials.

Learn more: Enhancing Wire Cable Production with Sialons

Choosing the right material for wire and cable guides ultimately depends on the specific demands of your operation. For high-temperature, abrasive applications where wear resistance and precision are crucial, ceramic guides are the best choice. Their ability to withstand extreme conditions ensures they will outlast tool steel and carbide, offering superior long-term value.