As we move through 2024, industrial progress is at a fascinating intersection. The rapid rise of automation and AI is reshaping operational paradigms, while ambitious global climate goals are accelerating the transition to renewable energy and sustainable practices. Across sectors, from manufacturing to energy and beyond, companies are embracing innovation to navigate a challenging global landscape defined by supply chain instability and economic pressures.

At the core of these transformations is a subtle yet significant revolution in materials. Advanced ceramics, especially silicon nitride and sialons, are becoming crucial for this new industrial era. Their outstanding thermal, chemical, and mechanical properties position them as vital contributors in tackling some of the most urgent needs of contemporary engineering: efficiency, durability, and environmental sustainability.

The Versatility of Advanced Ceramics

Few materials have managed to match the unique versatility of advanced ceramics. These types of ceramics can withstand extreme environments with unmatched durability that makes them invaluable across various industries. Silicon nitride and sialons, for example, are redefining the performance standards of critical components like pumps, valves, and cutting tools in sectors such as chemical processing, metal forming, and foundries.

Unlike conventional materials, these ceramics excel where others falter. In chemical processing, sialons resist corrosive substances. Their corrosion resistance helps to defend equipment against chemical attack. This can lower the amount of repairs that are needed and improve durability, reducing maintenance costs in the process. In foundries, silicon nitride endures intense thermal and mechanical stress, improving reliability and efficiency. These advantages, coupled with their long lifespans, are driving widespread adoption across applications that demand uncompromising performance.

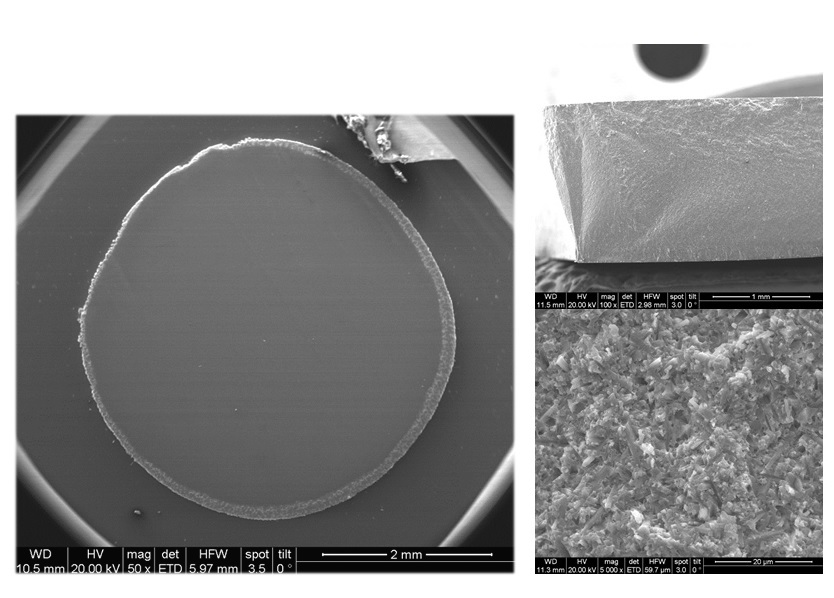

SEM and optical microscopy images showing the microstructure of a Syalon 101 (beta-sialon) fracture surface. Image Credit: International Syalons (Newcastle) Ltd.

Sustainability and Green Technologies

The global push for sustainability is transforming the way industries approach material selection and process design. Foundries, traditionally energy-intensive, are embracing advanced heat recovery systems and renewable energy integration to reduce emissions. Similarly, the chemical process industry is pivoting toward green chemistry and closed-loop systems to minimize waste.

Advanced ceramics are uniquely aligned with these sustainability goals. The longevity of advanced ceramics not only reduces material consumption but also supports energy efficiency in high-demand applications. Sialons, for example, maintain their integrity in energy-efficient furnaces, enabling processes to run cleaner and longer. In this way, advanced ceramics are more than just functional. They’re critical to the evolution of greener, more responsible manufacturing practices.

Navigating Supply Chain Challenges

The complexities of global supply chains have deepened in 2024, as industries contend with geopolitical tensions and resource scarcity. Advanced ceramics offer a compelling solution to these challenges by providing superior durability and reducing dependence on raw materials subject to volatility.

In sectors like metal forming, where supply fluctuations in steel and aluminum can disrupt operations, ceramics including silicon nitride provide a reliable alternative. Their integration helps stabilize production schedules and ensures business continuity, even amid external pressures.

Moreover, technological advancements like AI-driven supply chain monitoring are enabling companies to manage their inventory more effectively. The stability and longevity of advanced ceramics align seamlessly with these digital tools. They deliver systems that are not only more robust but also more predictable.

Innovations in Manufacturing

The manufacturing processes surrounding advanced ceramics have undergone remarkable transformation, unlocking new possibilities for precision and complexity. Hybrid techniques that blend additive manufacturing with traditional methods help produce highly specialized parts, minimizing waste and production time.

At the same time, precision machining has reached new heights. Companies, including ourselves, International Syalons, are at the forefront of this innovation, delivering bespoke ceramic components that meet the stringent requirements of modern industrial applications. These advancements are particularly valuable in fields like aerospace and automotive manufacturing, where the demand for lightweight, high-performance materials continues to grow.

Sialon Protection Tubes – Image Credit: International Syalons (Newcastle) Ltd.

A Material for the Future

The continued adoption of advanced ceramics is as much about future readiness as it is about current performance. These materials epitomize resilience, a quality increasingly prized in a world of uncertainty. Beyond their technical attributes, they represent a strategic investment in sustainability, efficiency, and reliability—qualities that define the industries of tomorrow.

Looking ahead, the potential for advanced ceramics is vast. Emerging trends, such as the development of high-performance polymers and advanced coatings, promise to expand ceramics’ applications further. As industries embrace digital transformation and sustainable practices, ceramics including silicon nitride and sialons have a central role to play in shaping this new industrial landscape.

Utilize Our Knowledge of Ceramics To Find The Materials You Need

As a pioneer in advanced ceramic solutions, International Syalons is proud to support industries in their pursuit of excellence. With decades of expertise, we deliver materials that not only meet but exceed the demands of modern engineering. Whether you’re looking to enhance operational efficiency, improve sustainability, or strengthen supply chain resilience, our experts are here to guide you.

Contact us today to explore how advanced ceramics can revolutionize your processes and position your business at the cutting edge of industrial innovation.