The U.S. National Academy of Engineering (NAE) highlighted reverse-engineering of the human brain as one of the world’s greatest research challenges in the 21st Century. It was established as a priority alongside the economization of solar power and the realization of fusion on earth. By incorporating the aim of breaking down human cognitive abilities and building systems that can replicate them onto this list, the NAE essentially brought the field of artificial intelligence (AI) and machine learning out of an exclusively digital space and into the remit of materials science. Advanced ceramic materials, alloys, composites, polymers, and more, are now at the forefront of AI research efforts.

Continue readingAuthor Archives:

Why Choose Silicon Nitride Welding Rollers?

Updated 17/03/2022:

Seam welding equipment is used to join the faying surfaces of unfinished cylindrical profiles (pipes, tubes, etc.). It exploits a similar principle to standard arc welding to produce a durable, longitudinal weld along the full length of a tubular workpiece. Ensuring this solid-state bond is uniform demands high process automation using high strength forming components. Turning rolls, or pipe rollers, are the key component differentiating seam welding from other joining methods like spot welding.

Continue reading

Silicon Nitride for Pump Components: Properties & Benefits

Pumping technologies are fundamental to success in an array of market sectors, from municipal water supplies to proprietary ultra-high vacuum (UHV) processing. Poor performance or malfunction in such applications can be extremely costly. Water loss due to leaks in pipelines is estimated to cost billions in annual revenue while inefficient vacuum leak rates in UHV processing can render experiment/production parameters void. These concerns are further amplified when pumps are required to operate in extreme conditions, which can cause conventional pump materials to deteriorate and fail.Continue reading

Syalons’ First Apprentices Receive Certificates

International Syalons (Newcastle) Ltd. is proud to announce that two of their apprentices have now completed their Advanced Modern Apprenticeship and HNC years 1 and 2.

Future of Technical Ceramics: AI, IoT & Industry 4.0

Ceramics have been exploited by mankind for over 26,000 years. They have been so central to human engineering that it is impossible to pinpoint a singular origin of the pottery-making process. Archaeologists have coined the term “linear pottery culture” to define the period when ceramics were simultaneously and independently discovered by different peoples across Neolithic Europe. Yet the significance of technical ceramics spans far beyond archaeological curiosity, pervading several key periods of history and every phase of industrial progress into the modern age and the future.

Continue readingDesign Tips for Silicon Nitride Ceramics

Silicon nitride ceramics (Si3N4) occupy a storied niche in the history of engineering materials, rising from relative obscurity in the early days of the industrial era to become one of the most important technical-grade ceramics available today. Since their renaissance in the early 1970s, silicon nitride ceramics have successfully replaced numerous legacy materials as the advanced ceramic of choice for various high-performance components. These include:

Continue readingSialon Vs Silicon Carbide

In the field of material technology, nonoxide technical ceramics are among the most recent developments. They are increasingly being used for a range of applications thanks to their chemical, thermal, and mechanical properties. Both sialon and silicon carbide (SiC) ceramics are useful candidates for energy conversion and production. Already, they have shown exceptional prowess in abrasive environmental applications and those which involve harsh chemicals. So, what are the differences between sialon and silicon carbide, and which applications does each best serve? Here, International Syalons takes a closer look.Continue reading

Comparing the Fracture Toughness of Zirconia Ceramics

Zirconia ceramics represent the primary application for the compound zirconium dioxide (ZrO2), accounting for over half of the world’s zirconium demand. Recent reports suggest that the global zirconia market will top 1.5 million tonnes by 2022; meaning global demand of the raw mineral purely for zirconia ceramics manufacturing could top 750,000 tonnes in a few short years. Estimates suggest that this is less than 1% of the world’s total zirconium reserves.Continue reading

Insight into the Hardness of Zirconia Ceramics

Zirconium dioxide (ZrO2) is one of the most well-characterised ceramic materials on earth. It occurs naturally in the mineral baddeleyite, which primarily adopts a monoclinic crystalline structure: one of the three primary forms of the material. The most widely-known form of zirconia is the cubic crystal phase which often serves as a cost-effective diamond substitute. However, estimates suggest that demand for zirconia ceramics accounts for as much as 54% of the worldwide zirconium market[1].

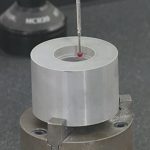

Ceramics Engineering: Pressure Vs. Pressureless Sintering

Sintering is arguably the most important step in the ceramics manufacturing process. It is the phase when the green-body is fired at temperatures approaching the ceramic powder’s melting point, causing the consolidated raw material to undergo numerous chemical and physical changes. Several distinct sintering methods exist, but each one essentially exploits the same properties of ceramics to form a densified workpiece with desired properties and material characteristics.Continue reading