Ceramics have transformed wire and cable manufacturing, making it possible to produce stronger, more heat-resistant, and longer-lasting components. But innovation comes with obstacles. Brittleness, high production costs, and thermal expansion mismatches can limit their use in wire and cable applications. Rather than barriers, these challenges are driving advancements in ceramic formulations, processing techniques, and hybrid materials, ensuring ceramics continue to push the industry forward.

Category Archives: Uncategorized

What role do advanced ceramics play in wire and cable drawing?

Wire and cable drawing is a fundamental manufacturing process used to produce precisely sized metal wires for applications in telecommunications, automotive, aerospace, and construction. The process involves pulling metal through a series of dies to reduce its diameter while ensuring uniformity. However, the extreme stress, friction, and heat generated in the wire and cable drawing process place significant demands on the materials used for drawing dies, guides, and capstans.

Traditional materials like tungsten carbide, while durable, suffer from wear over time. This leads to frequent replacements and increased operational costs. Advanced ceramics, Silicon Nitride (Si₃N₄), Sialon (Si-Al-O-N), Zirconia (ZrO₂), Alumina (Al₂O₃), and Silicon Carbide (SiC), offer a superior alternative. The exceptional hardness, wear resistance, and thermal stability of these advanced ceramics make them indispensable in improving efficiency, extending tool life, and enhancing the quality of drawn wire.

How shock waves cause electrical insulator failure—and how to prevent it

High-voltage plasma arcs are indispensable in water treatment, industrial cleaning, waste processing, and more. These industries rely on arc plasma technology to generate intense energy bursts that drive essential chemical and physical processes. However, one significant challenge associated with plasma arcs is the generation of powerful shock waves, which can severely damage electrical insulators at the cathode and anode.Continue reading

Advanced Ceramic Materials: Innovation and Industry Trends in 2024

As we move through 2024, industrial progress is at a fascinating intersection. The rapid rise of automation and AI is reshaping operational paradigms, while ambitious global climate goals are accelerating the transition to renewable energy and sustainable practices. Across sectors, from manufacturing to energy and beyond, companies are embracing innovation to navigate a challenging global landscape defined by supply chain instability and economic pressures.

At the core of these transformations is a subtle yet significant revolution in materials. Advanced ceramics, especially silicon nitride and sialons, are becoming crucial for this new industrial era. Their outstanding thermal, chemical, and mechanical properties position them as vital contributors in tackling some of the most urgent needs of contemporary engineering: efficiency, durability, and environmental sustainability.

Understanding Ceramic Innovations in Wire Braiding

Wire braiding, a specialised process used in industries from aerospace to telecommunications, has undergone significant advancements in recent years—particularly through the integration of technical ceramics. Materials like sialons and silicon nitride are advantageous for the wire braiding industry owing to their high performance under extreme conditions. Here, we’ll explore how ceramic innovations support efficiency, longevity, and performance improvements in wire braiding applications.Continue reading

Developing and Implementing a Standardised Approach to Testing Silicon Nitride Based Ceramics

At International Syalons Ltd, each of our silicon nitride-based ceramic grades are manufactured onsite from high purity raw materials, and every batch is rigorously analysed using various testing methods, ensuring we continue to produce high quality engineering components.

The Role of Wear-Resistant Ceramics in Extending Equipment Life

In industries like mining, oil and gas, and chemical processing, operational endurance depends on machinery that can withstand relentless wear. Equipment failure disrupts productivity and spikes maintenance costs. The solution? High-performance abrasion-resistant ceramics such as silicon nitride, silicon carbide, and alumina. These materials lead the charge in extending the lifespan of machinery and reducing breakdowns, reshaping efficiency in high-demand environments.Continue reading

How theory and practice differ in high-strength ceramics

High-strength ceramics serve some of the most demanding applications on—and off—earth. These advanced materials, like sialons, are among the strongest mankind has ever engineered and are theoretically capable of withstanding tremendous forces. Why, then, does reality often fall short? Even when performing above user expectations, some ceramics fail to live up to their own promise. This doesn’t generally represent a technical concern, given that engineering ceramics’ real-world performance often eclipses that of traditional materials by orders of magnitude. Yet it could serve as a barrier to future innovation and truly astronomical efficiency gains. Let’s explore why ceramics may fall short of their theoretical strength and what’s being done to bridge the gap.

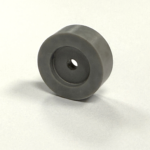

Choosing the Right Wire and Cable Guides: Comparing Ceramic, Tool Steel, and Carbide Materials

When selecting the right wire and cable guides, choosing the best material is crucial for maximizing efficiency, reducing maintenance costs, and ensuring long-lasting performance. Three common materials—ceramic, tool steel, and carbide—each offer distinct advantages and limitations in this context. Let’s compare them in detail, highlighting why ceramic materials are often the superior choice, particularly in challenging high-wear environments

Essential Considerations When Choosing the Right Technical Ceramics Manufacturer

Selecting the right technical ceramics manufacturer is a critical decision that impacts the performance and durability of products across industries such as aerospace, automotive, and molten metal handling. The right partner will ensure that your components perform reliably in extreme conditions—whether it’s resisting high temperatures, withstanding corrosive environments, or enduring heavy wear.