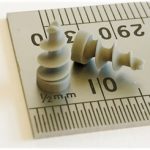

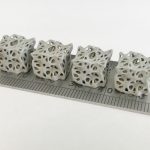

Lithographic additive manufacturing of advanced ceramics is an emergent technology that is unlikely to replace conventional bulk sintering and machining any time soon – if ever. This is due, primarily, to the scale and precision of components manufactured via 3D printing.

Continue readingCategory Archives: Uncategorized

Creating High Temperature Microturbines with 3D Printing

Armed with innovative 3D printing technologies, engineers have designed a new generation of microturbines capable of unparalleled operating efficiency at higher speeds and elevated temperatures.

Continue reading3 Key Benefits of 3D Printed Ceramic Materials

As part of the European Commission funded Horizon 2020 project ToMax, International Syalons in collaboration with European partners has demonstrated the unique capabilities of lithographic-additive manufacturing (L-AMT) of ceramic materials including Syalon 101.

Continue readingA Quick Intro to Additive Manufacturing Ceramic Solutions

Additive manufacturing (AM) of ceramics, also known as ceramic 3D printing, is an attractive engineering solution for challenging applications. Technical ceramics, like silicon nitride (Si3N4), largely outperform industrial-grade polymers and metals for high-temperature operations, with superior mechanical properties and thermodynamic stability. Yet these same properties make ceramics difficult to use as a feedstock in additive manufacturing processes.

Continue readingInternational Syalons and SILCA at Hannover Messe 2019

Visit International Syalons and SILCA/Calsitherm at Hannover Messe 1–5 April 2019 at Stand L08, Hall 3, in the Ceramic Applications area.

Outlining Diamond Grinding of Ceramics

Advanced ceramics manufacturing comprises three essential stages: raw powder processing; forming; and sintering. This generally describes the process of consolidating a powder-based feedstock and firing the green body to achieve a fully-densified technical ceramic. Net shapes with comparatively loose dimensional tolerances (~1-3%) can typically be produced ‘as-sintered’; requiring no machining or finishing prior to quality assurance inspections. Components with tight tolerances cannot be produced ‘as-sintered’ and may require diamond grinding to ensure that the net shape is usable according to the design intent.

Continue readingBritish Ceramic Confederation Membership

International Syalons are delighted to announce their British Ceramic Confederation (BCC) membership.

The BCC are a professional organisation who represent the collective interest of all sectors of ceramic manufacturing in Britain by working extremely hard to safeguard the industry’s prosperity and lead sector discussions and negotiations with Government and public authorities.

Continue reading

Syalon 101 Extrusion Dies for Copper, Brass, and Nimonic Alloys

Extrusion describes the process where a metal such as copper or brass is forced through an extrusion die with a smaller cross-section. This deforms the material, causing a lengthening of its granular structure and forcing it to adopt a new cross-section uniformly across the entire manufactured workpiece. It is an extremely common metal forming process used to convert cylindrical billets into hollow tubes, or more complex profiles and sections.

Continue readingZircalon 30 – A New Grade of Fracture-Resistant Zirconia Ceramic for Welding Applications

International Syalons are pleased to announce the availability of Zircalon 30 a new grade of zirconia-based advanced ceramic with greatly improved fracture toughness, which is ideal for induction welding applications.

Continue readingCeramic Materials in Defence Applications

The 20th Century was an era of rapid innovation in ballistics technology, and subsequently in how conflicts were conducted. Military organisations worldwide opted to improve the manouverability of troops and vehicles without compromising the performance of protective equipment in response to high velocity impacts. This led to the gradual adoption of novel ceramic materials in defence applications.Continue reading