INDUSTRIES

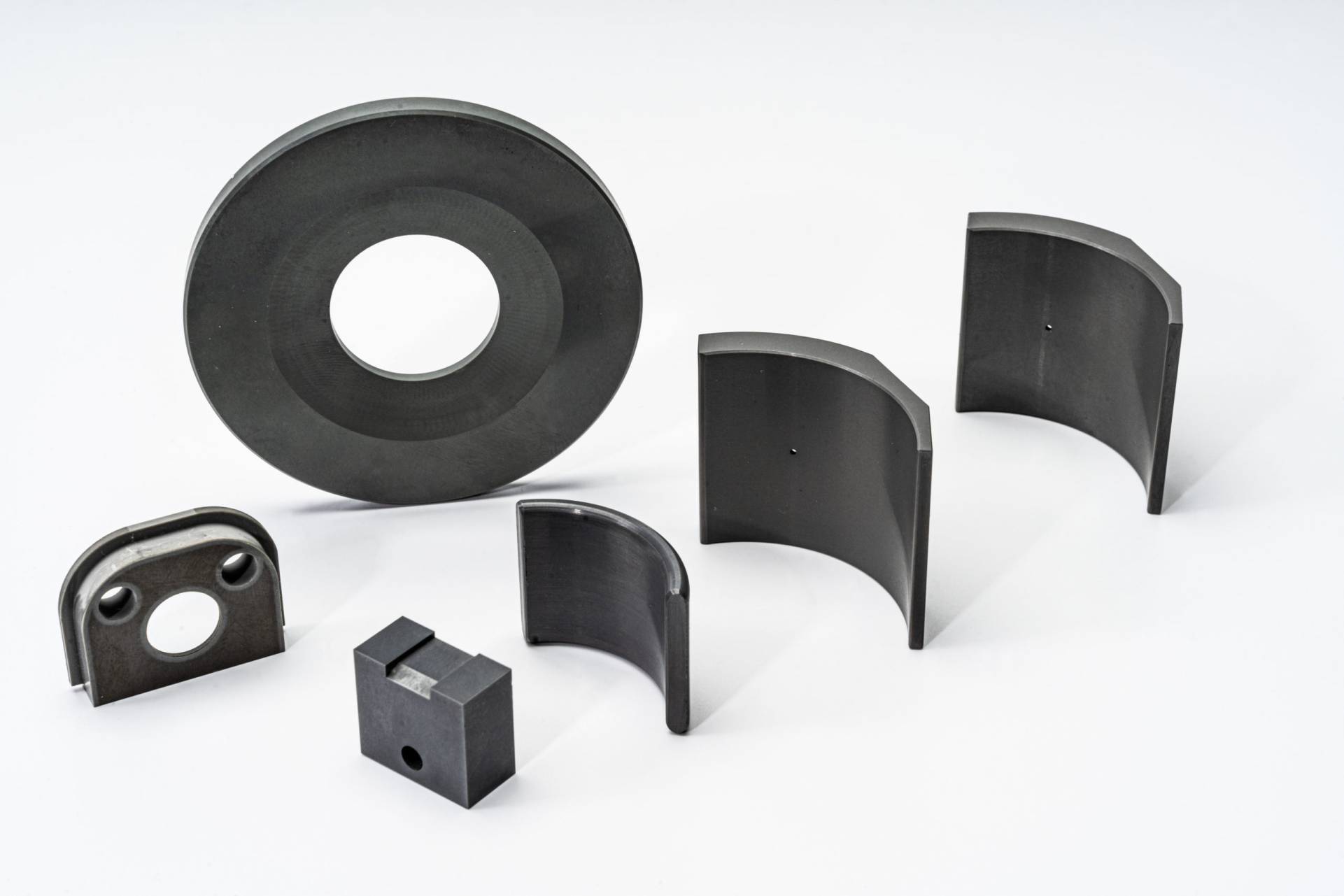

Few of the amenities, commodities, and products that we enjoy in developed societies would be possible without the ubiquitous implementation of precision engineered materials like technical ceramics. Advanced ceramic materials are now ubiquitous in modern engineering and industrial markets.

FOUNDRY APPLICATIONS

Sialons and in particular Syalon 101 are renowned for their exceptional performance in non-ferrous molten metal handling. Syalon 101 is used extensively for products such as thermocouple protection tubes, radiant and immersion heater protection tubes, high and low pressure riser tubes and stalks, and a wide range of foundry accessories including ladles, crucibles and hooks.

INDUSTRIAL PROCESSING

Advanced engineering ceramics are characterised by excellent mechanical strength and hardness, making them ideal candidates for wear applications too extreme for metals and alloys. These include for example paper processing dewatering foils and shot blasting of abrasive grits.

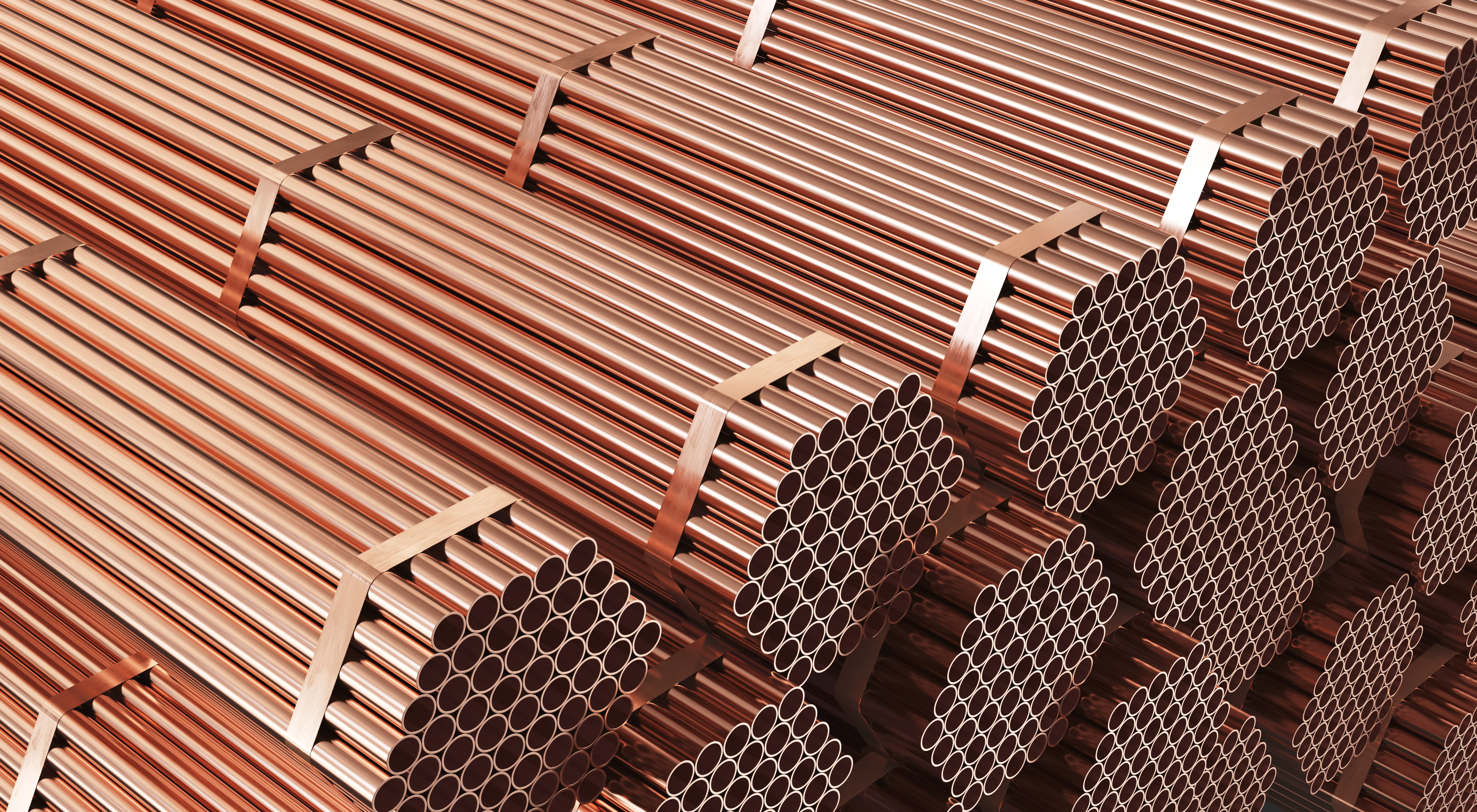

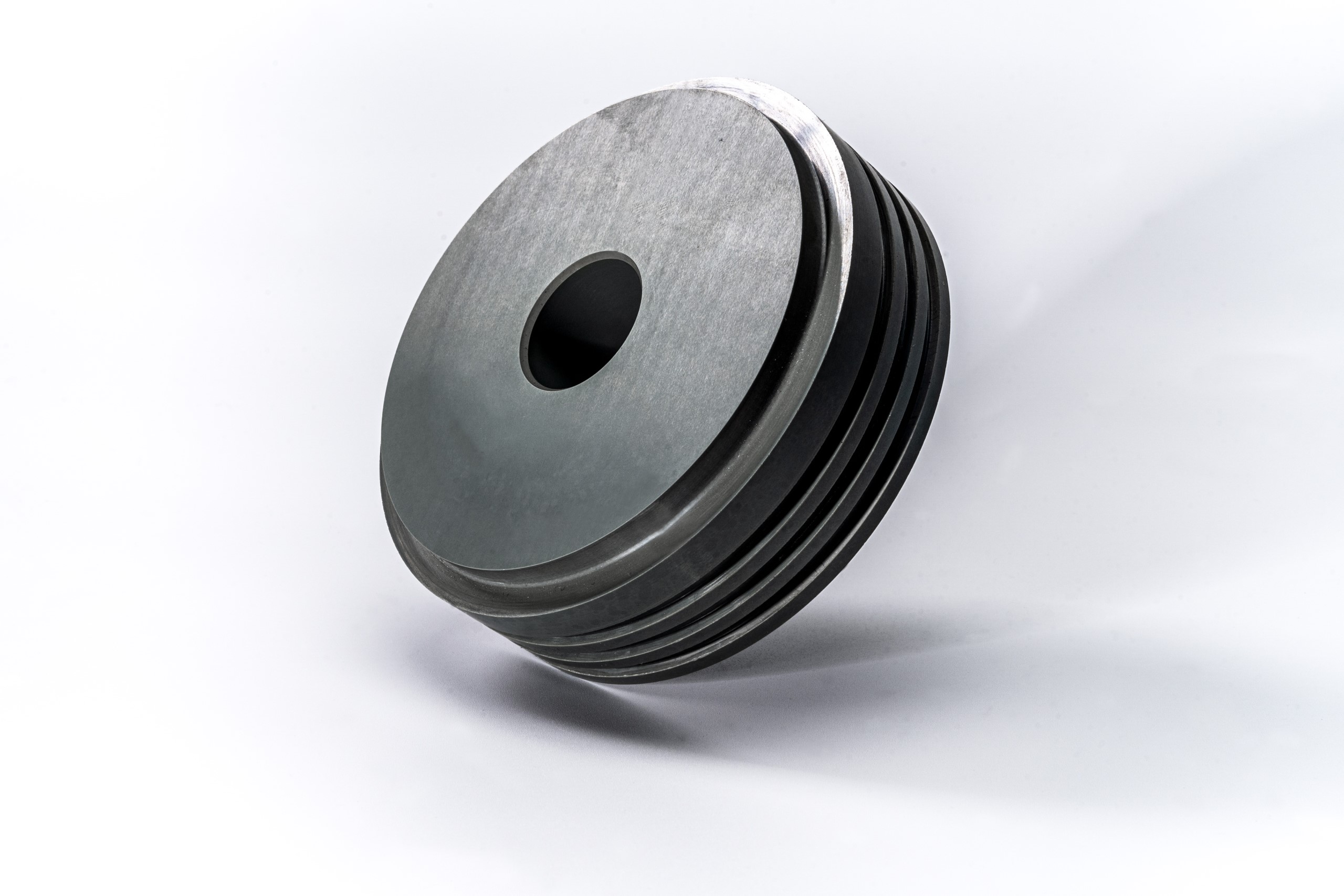

METAL FORMING

Silicon nitride and zirconia, utilising their outstanding high strength and toughness, are used extensively in metal forming applications such as wire drawing of copper and brass, as weld location and control pins for resistance welding of captive nuts to body panels and as cutting tools for cast iron.

CHEMICAL AND PROCESS

The excellent corrosion and thermal resistance of our silicon nitride and silicon carbide ceramics to many acids and alkalis makes them ideal candidate materials for use in the chemical and process industries. For example, as inlets liners in industrial chlorinators.

THERMAL PROCESSING

Advanced ceramics are generally charcterised by possessing excellent thermal properties, such as high melting temperature. International Syalons offer a range of thermal ceramics such as alumina tubes and thermocouple sheaths.

OIL AND GAS

The oil and gas industries utilise advanced ceramic materials such as silicon nitride, alumina and zirconia for components including hydrocyclones and metering valves, where excellent wear, corrosion and thermal resistance are required.

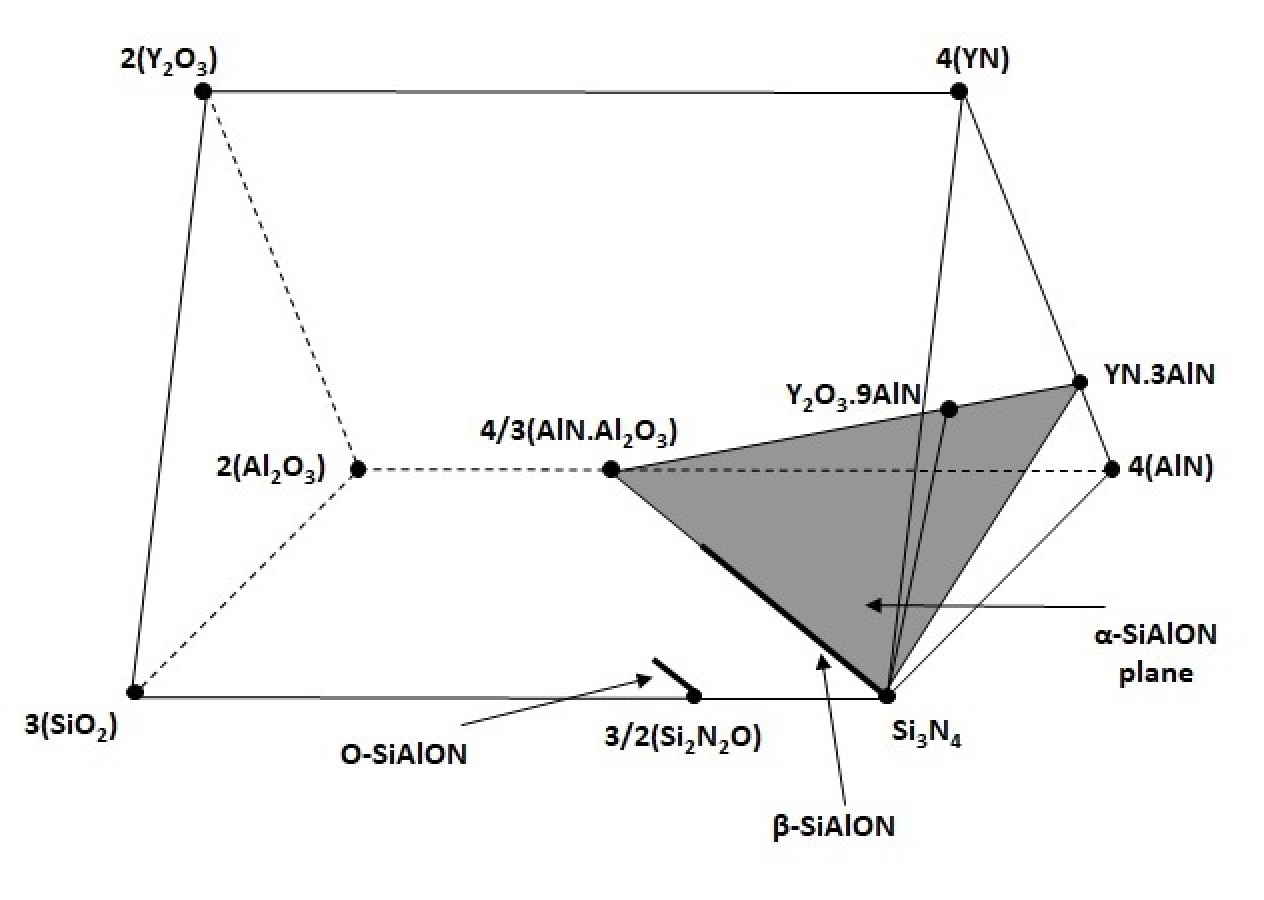

What are sialon ceramics?

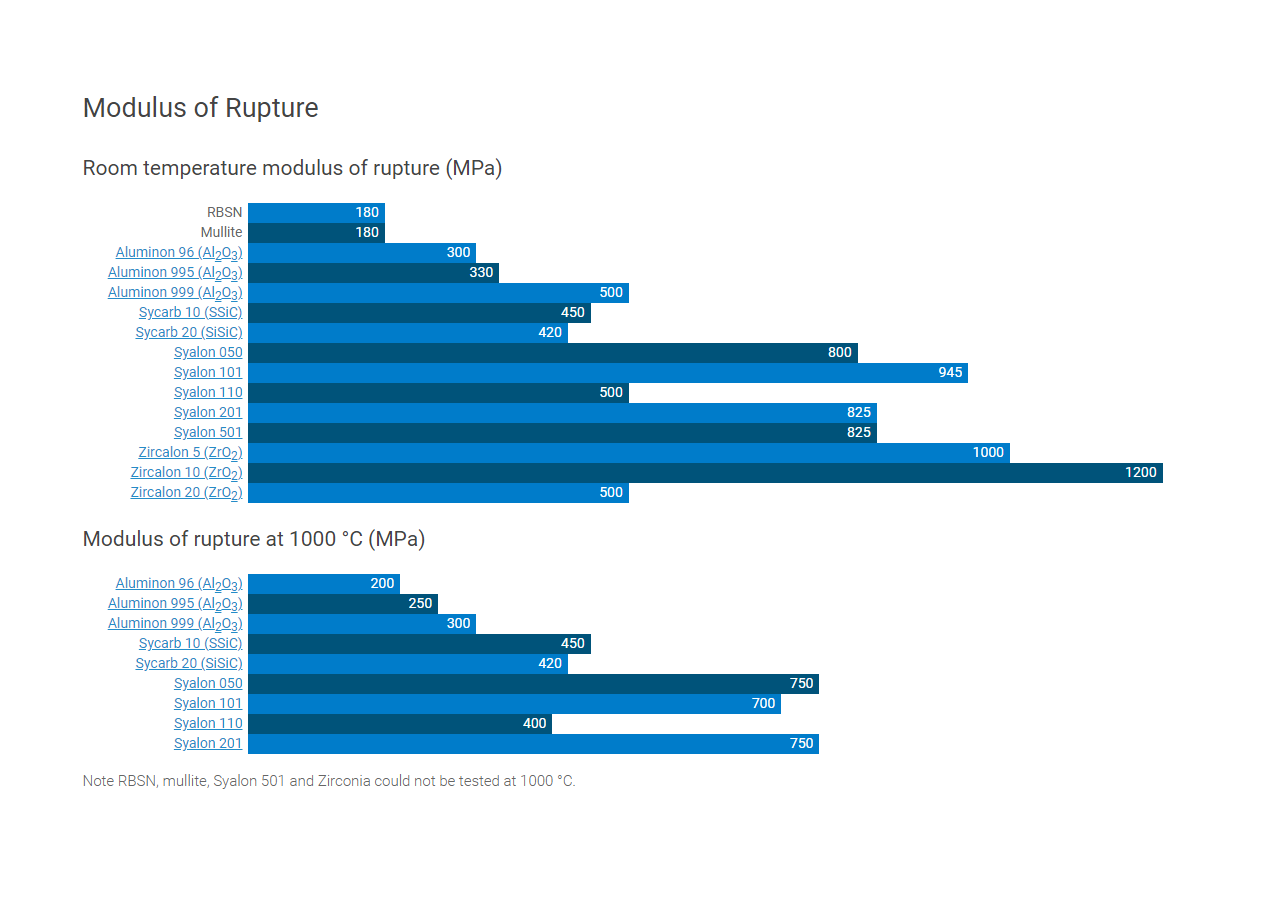

Technical ceramic property comparison table

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Zircalon 30 is a co-stabilised zirconia-based ceramic with an alumina matrix, which is reinforced by self-grown alumina-based platelets and offers outstanding fracture toughness.

Providing unmatched performance properties under extreme levels of stress, advanced ceramics help designers and engineers to push production boundaries and deliver innovative solutions to the many industrial challenges we face today. Advanced ceramic materials promote greater efficiency throughout manufacturing and production chains, by withstanding severe stress with little-to-no loss of function over time. Technical ceramics represent some of the hardest wearing engineered materials on earth, which translates to unprecedented erosion resistance and industrial wear performance.

The advanced ceramics available from International Syalons are extremely stable and fully dense, which imparts outstanding resistance to corrosion in chemical and process industries. Virtually all advanced ceramic materials also exhibit superb thermal properties, enabling their application in a comprehensive range of extreme temperature environments.

Advanced ceramics are on the forefront of technical achievement in engineering and industrial processing, from clean energy development to ultrafast telecommunications. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team or send us a Request for Quote.