CHEMICAL ENGINEERING AND PROCESSING

Chemical engineering is a challenging prospect. Processing equipment must be compatible with various chemistries (acidic substances versus alkaline solvents) while withstanding extreme temperatures and pressures. The strain this puts on material selection for mechanical seals and tubes is significant, particularly from a total cost of ownership (TCO) perspective. Chemical & Process Industries (CPI) are always on the lookout for innovative materials that can prolong the lifespan of essential components.

At International Syalons, we understand the unique challenges faced by procurement managers in the Chemical & Process Industries (CPI). That's why we specialize in providing advanced ceramic solutions, including silicon nitride, zirconia, alumina, and silicon carbide, tailored to address the wear and corrosion challenges inherent in CPI applications.

Our advanced silicon nitride, sialon, and silicon carbide ceramics are renowned for their exceptional resistance to corrosion across a broad temperature spectrum. This makes them ideal for the rigorous demands of the chemical and process industry markets. With their superior wear, corrosion, and thermal resistance properties, our Syalon and Sycarb ceramics stand out as the go-to choice for ensuring longevity and operational efficiency.

Choosing the right supplier is crucial for CPI procurement managers. International Syalons not only offers advanced ceramic solutions but also understands the intricacies of the CPI sector. Partner with us to ensure that your operations benefit from the best in ceramic technology, tailored to meet and exceed industry demands.

Enhance the reliability and performance of your pumping systems with plates or seals crafted from Sycarb or Syalon 101. Known for their exceptional wear and corrosion resistance, they ensure optimal operation across diverse environments.

We offer an extensive range of Syalon tubes, ideal for transporting highly corrosive chemicals. For instance, our Syalon 101 tubes have successfully replaced inconel tubes, significantly extending the operational life of chemical reactors.

Our Syalon 101 impellers are specifically designed for challenging applications, such as mixing hot sulphuric acid. Their superior corrosion resistance against various acids and alkalis makes them a preferred alternative to conventional materials, offering enhanced performance and durability.

Explore the discovery of sialon ceramics

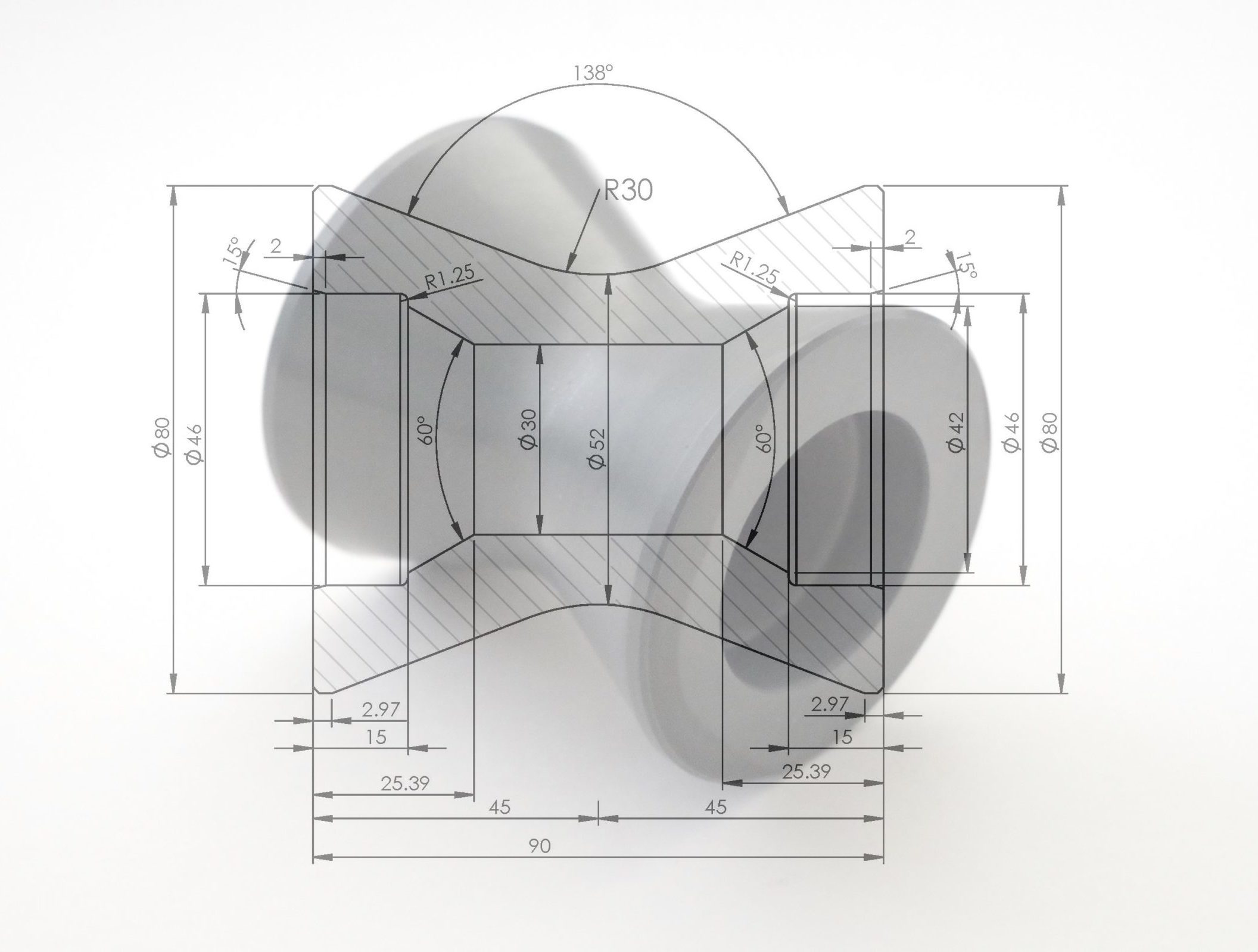

Learn how to design with ceramics

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

The temperature and corrosion resistance properties of sialon have been utilised in a range of foundry products for molten metal handling.

Silicon nitride, zirconia, and alumina ceramic offer outstanding refractory properties and thermal stability.