OIL AND GAS APPLICATIONS

International Syalons supplies advanced silicon nitride, zirconia, alumina and silicon carbide ceramic solutions for diverse oil & gas industry applications, utilising their outstanding wear and corrosion resistant properties.

Advanced silicon nitride and sialon and zirconia ceramics are finding application in the very demanding oil and gas market. As existing supplies of oil and gas are depleted, these industries are being forced to explore ever more severe environments for future supplies.

To help in this exploration, oil and gas companies are utilising the excellent wear, corrosion and thermal resistant characteristics of silicon nitride and zirconia. Their ability to resist corrosion and erosion, their light weight and heat tolerance, are resulting in them replacing traditional metal components in applications, such as:

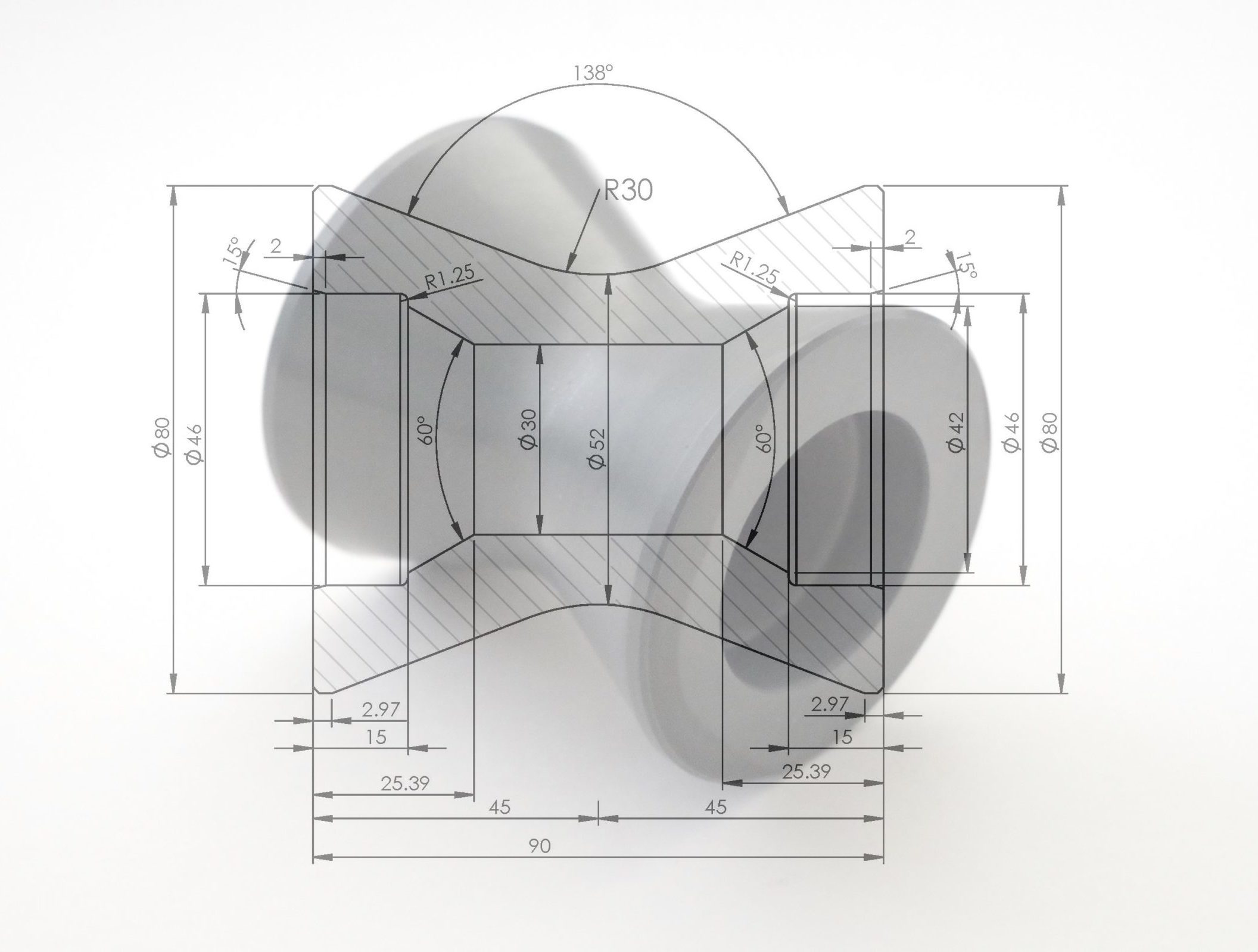

Oil companies have used Syalon 101 vortex hydrocyclones for removing sand from offshore oil, utilising its excellent erosion resistance.

With it's outstanding wear resistance, Syalon 050 metering valves have outperformed Inconel and silicon carbide in a cyclic sub-sea application.

Explore the discovery of sialon ceramics

Learn how to design with ceramics

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.

Silicon nitride offers excellent corrosion and thermal resistance and are ideal materials for use in the chemical and process industries.