THERMAL PROCESSING EQUIPMENT

Durability is essential to the longevity of high-temperature thermal processing equipment. It underlies process efficiency and long-term service performance. Process industries with extreme temperature ranges, whether in heat treating or exothermic chemistry, require robust materials. These are core to unlocking efficiency gains that maximise productivity, process yields, and optimal maintenance regimes. At International Syalons, we specialise in technical ceramics designed for demanding, high-temperature processes.

High-temperature ceramics, such as alumina, silicon carbide, silicon nitride, and zirconia, set the performance benchmark for applications like metal handling, forming, and glass production. Characterised by high-temperature resistance and melting points as high as 2730°C, fine ceramics are ideal for long-service thermal processing equipment. Ceramic materials are also inherently thermal shock-resistant and boast unparalleled thermal conductivity.

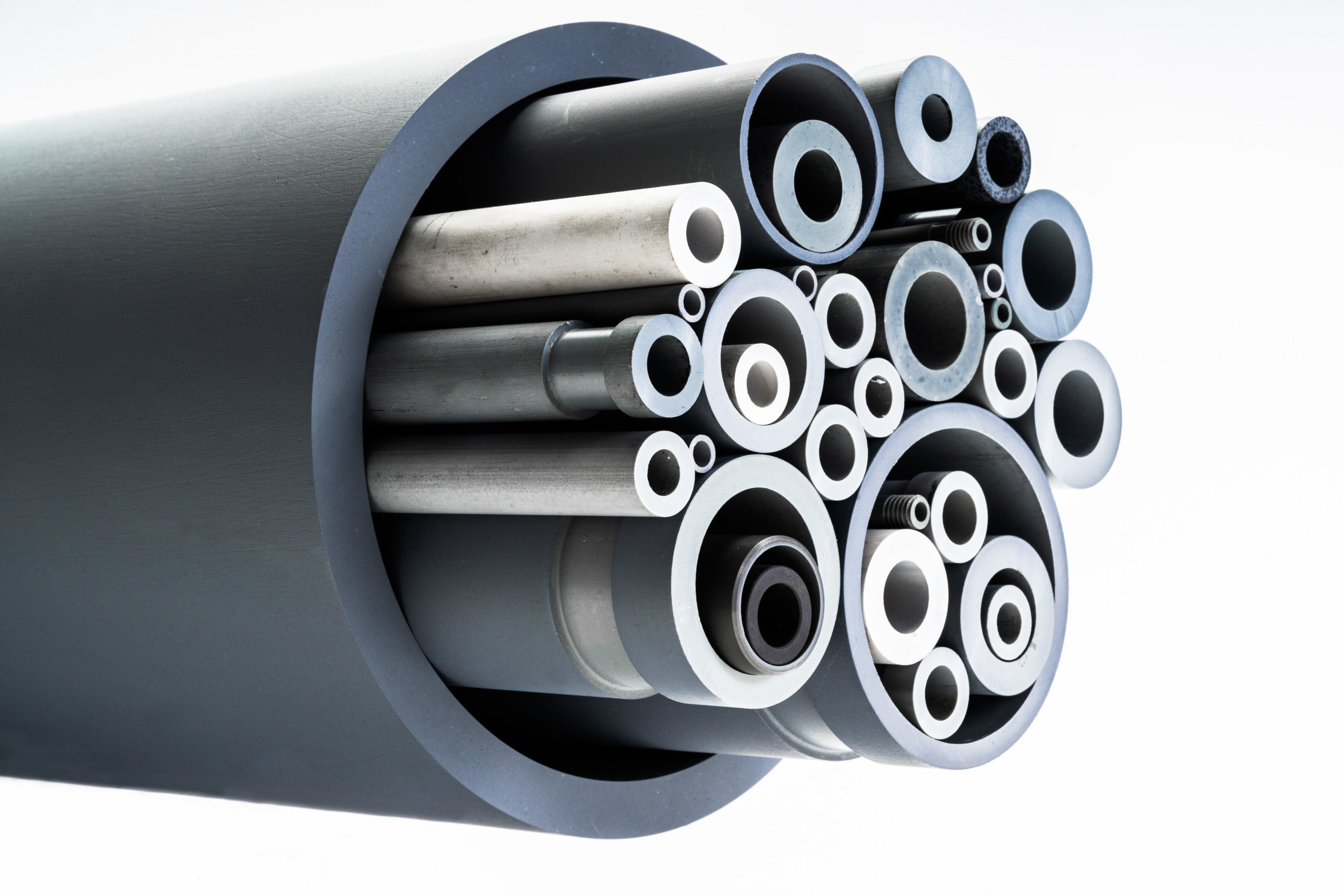

Sialons, for example, provide a perfect platform as ceramic tubes for high temperatures and high-temperature thermocouple protection tubes. Alumina ceramic tube is typically used as a thermocouple protection sheath or as a support for kiln insulation. Silicon carbide can be used as kiln furniture. Silicon nitride is used as a burner nozzle and is the standard material for non-ferrous molten metal handling applications.

Typical high-temperature thermal applications include:

Syalon 101 thermocouple protection sheaths are becoming the industry standard in non–ferrous metal foundries. They possess outstanding thermal shock resistance, high thermal conductivity, are non–wetting, and suffer no degradation in contact with aluminium and its casting alloys.

We offer an extensive range of Syalon tubes and bushes, ideal for transporting highly corrosive chemicals. For instance, our Syalon 101 tubes have successfully replaced Inconel tubes, significantly extending the operational life of chemical reactors.

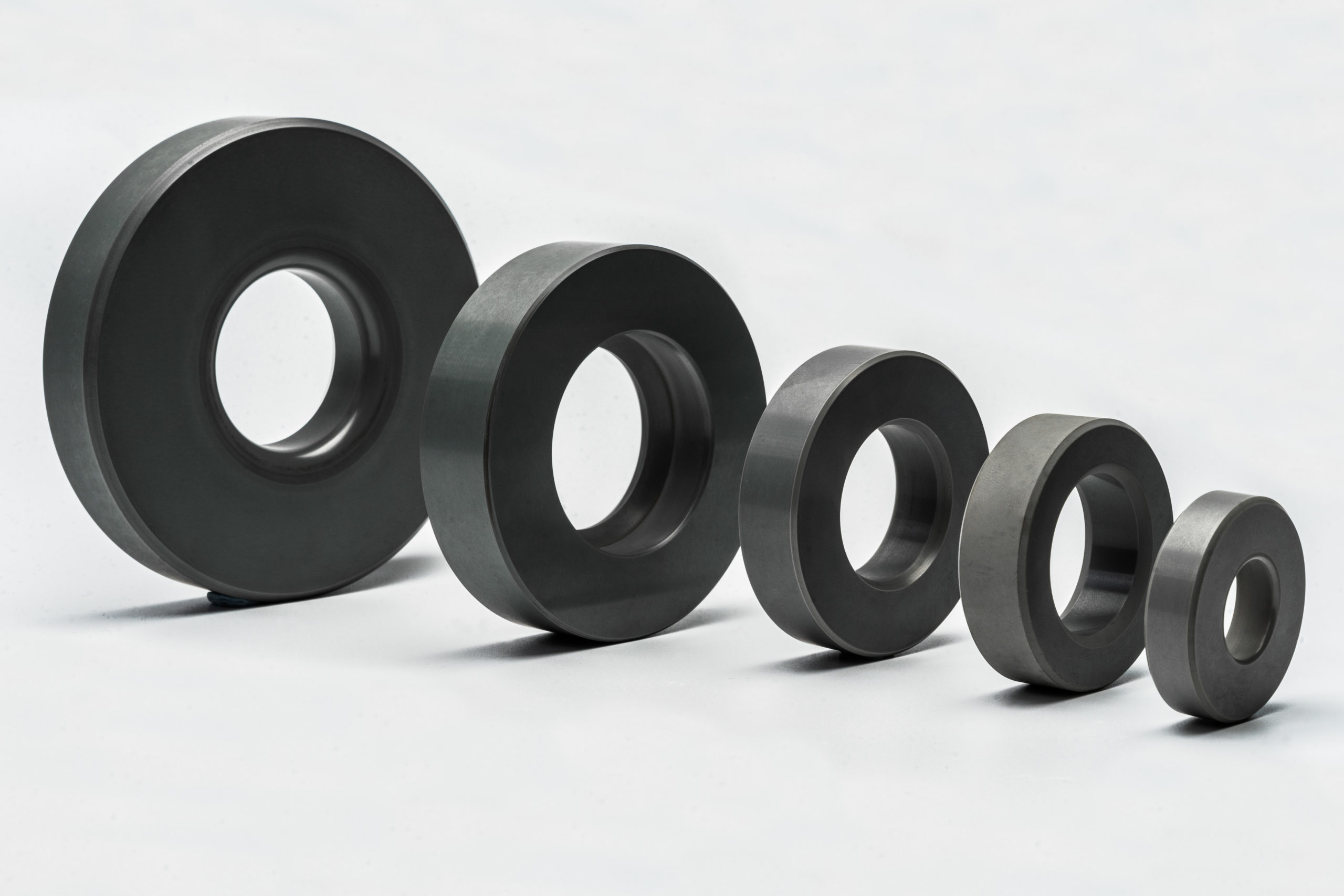

Drawing and extrusion dies require high strength and outstanding wear resistance, dimensional stability and the ability to give an excellent surface finish. Syalon 101 meets these requirements, as well as having excellent thermal shock resistance.

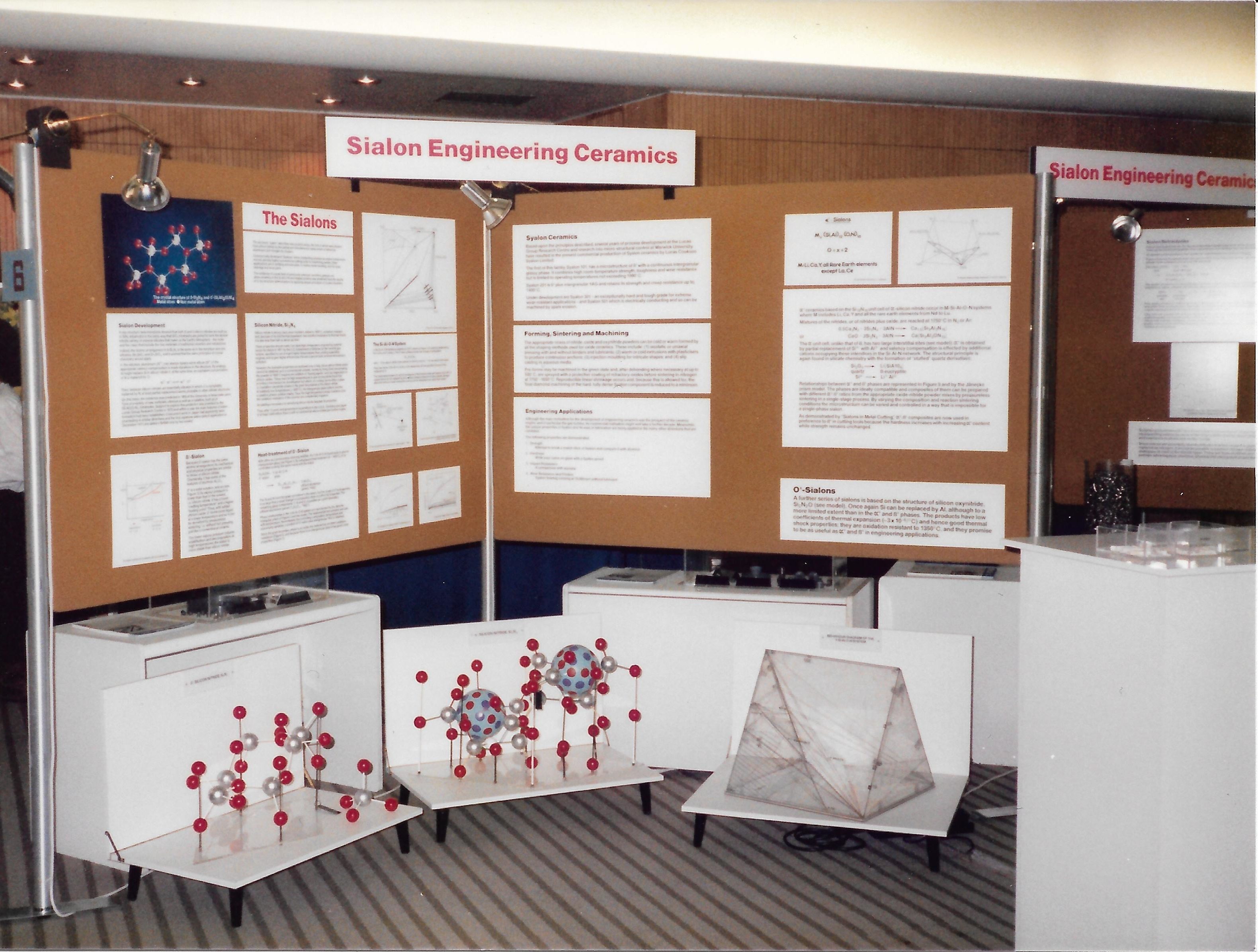

Explore the discovery of sialon ceramics

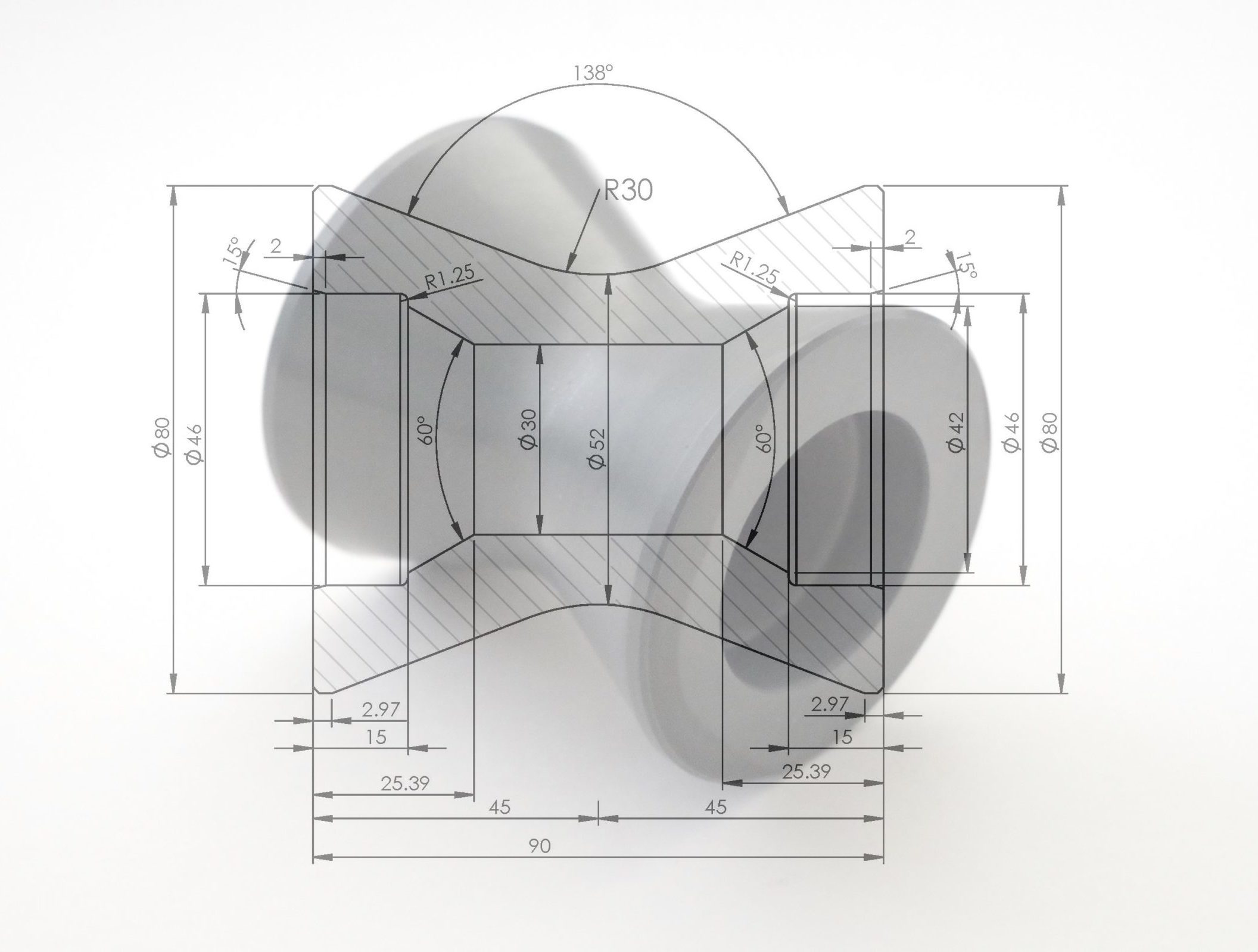

Learn how to design with ceramics

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

The temperature and corrosion resistance properties of sialon have been utilised in a range of foundry products for molten metal handling.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.