ZIRCONIA CERAMIC

Zirconium dioxide, more commonly known as zirconia (ZrO₂), is the toughest of the technical ceramics. Conventional zirconia ceramics are often limited in their capabilities by poor thermal performance, despite their high strength and practically unmatched hardness characteristics. Complex zirconia and stabilising additive combinations offer enhanced thermal stability, enabling manufacturers to exploit the outstanding mechanical characteristics of zirconia in more demanding high temperature environments.

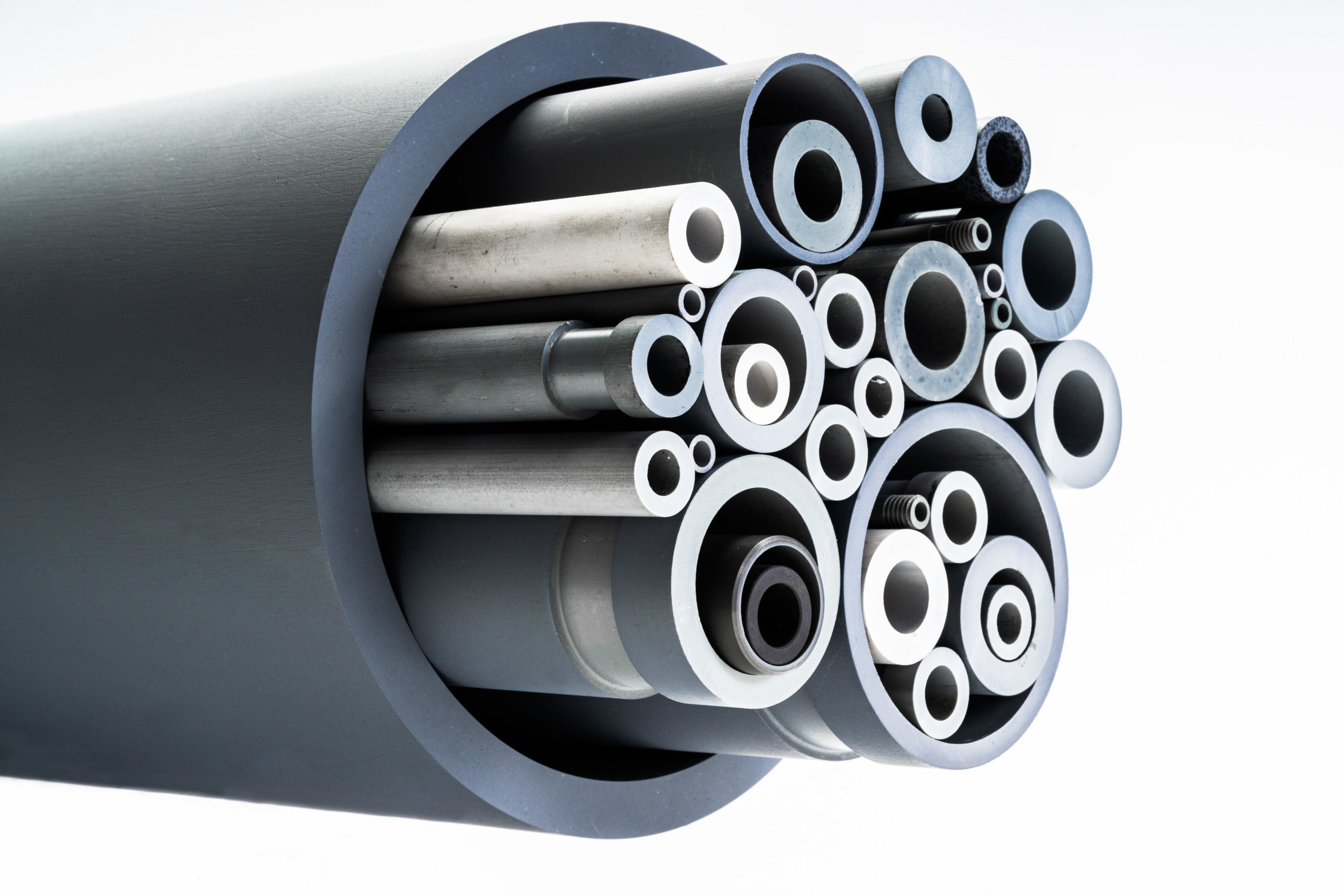

International Syalons is a specialist supplier of advanced engineering materials for a wide range of market segments. We offer a range of oxide and non-oxide ceramics for extremely challenging application areas. Among our core line is a choice of magnesia- and yttria-stabilised zirconia grades which have a negligible propensity for phase transitioning at high operating temperatures. We can subsequently supply hard-wearing zirconia ceramics for temperature-critical applications. Key performance indicators of our zirconia range include:

- Unprecedented fracture toughness (15 MPa m½)

- High modulus of rupture (1200 MPa)

- Excellent compressive strength (1600 MPa)

- Exceptional hardness (91 HRA)

Preventing zirconia from undergoing temperature-induced phase transitions is vital to success in high-temperature applications. By carefully controlling the alloying composition with stabilising additives, we can impart enhanced thermodynamic properties that maximise the performance and lifetime of hard-wearing parts.

Browse a selection of our zirconia ceramic grades below to find out more about their applicability and properties.

Zircalon 5

Zircalon 5 is an yttria stabilised zirconia (YSZ) and has very good strength and toughness. The table below lists typical mechanical, thermal and electrical property data for Zircalon 5.

Download the Zircalon 5 Property Datasheet

Zircalon 5 - Physical Property Data

Zircalon 10

Zircalon 10 is an yttria stabilised zirconia (YSZ) and has higher strength and toughness than Zircalon 5. The table below lists typical mechanical, thermal and electrical property data for Zircalon 10.

Download the Zircalon 10 Property Datasheet

Zircalon 10 - Physical Property Data

Zircalon 20

Zircalon 20 is a magnesia stabilised zirconia (MSZ) and has better thermal shock resistance than either Zircalon 5 or Zircalon 10. The table below lists typical mechanical, thermal and electrical property data for Zircalon 20.

Download the Zircalon 20 Property Datasheet

Zircalon 20 - Physical Property Data

Zircalon 30

Zircalon 30 is a co-stabilised zirconia-based ceramic with an alumina (Al₂O₃) matrix, which is reinforced by self-grown alumina-based platelets. Zircalon 30 has a better fracture toughness and thermal shock resistance than Zircalon 10, whilst still offering excellent mechanical strength and hardness properties. The table below lists typical mechanical, thermal and electrical property data for Zircalon 30.

Download the Zircalon 30 Property Datasheet

Zircalon 30 - Physical Property Data

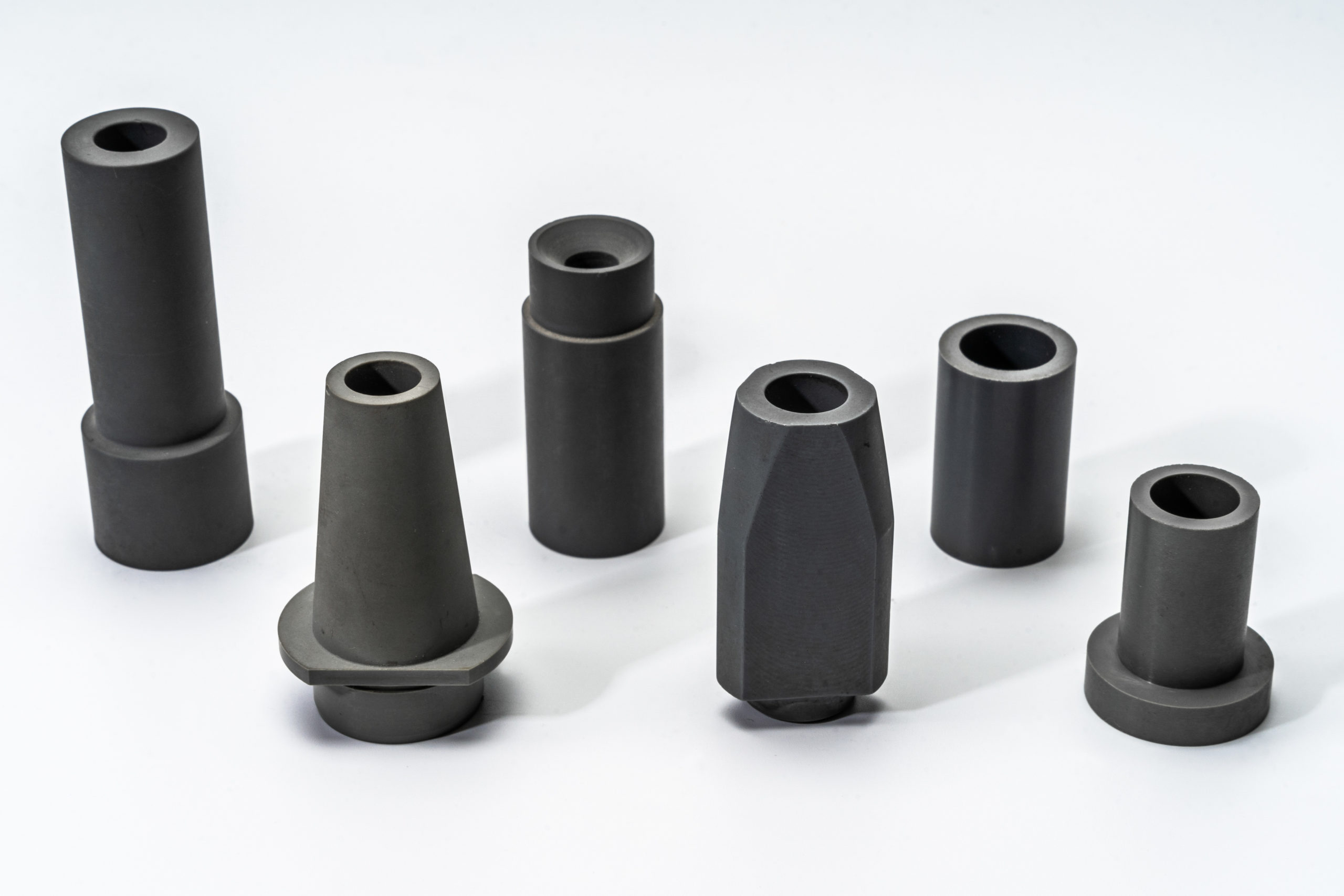

In addition to this outstanding property data, Zircalon also has excellent resistance to corrosion, often required for applications in the chemical and process industries.

The table below show the corrosion resistant behaviour of Zircalon in various acids and alkalis.

Zircalon - Corrosion Behaviour in Acids and Alkalis

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

In addition, see our resources section for guides on designing with ceramics and more property data comparing zirconia with other engineering ceramics.

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries.

Syalon is the preferred choice when looking to improve nozzle wear resistance, outperforming many competitive materials such as alumina and tungsten carbide.

International Syalons manufacture a range of standard and bespoke silicon nitride and zirconia ceramic weld location and control pins, which are used for precise captive nut welding.