TECHNICAL CERAMIC PRODUCTS

Technical ceramic components offer unique opportunities for materials engineers and procurement specialists to optimise manufacturing processes, yielding enormous efficiency gains and long-term cost savings. Processing industries are fraught with dynamic challenges. Aggressive chemistries, high temperatures, and complex wear mechanics demand high-performance solutions with finely tailored material properties.

At International Syalons, we engineer advanced ceramics to withstand the most difficult conditions in modern industry, ensuring long-term performance reliability in the face of challenging use cycles and sustained high throughput. Where conventional metal alloys fail, technical ceramic products excel.

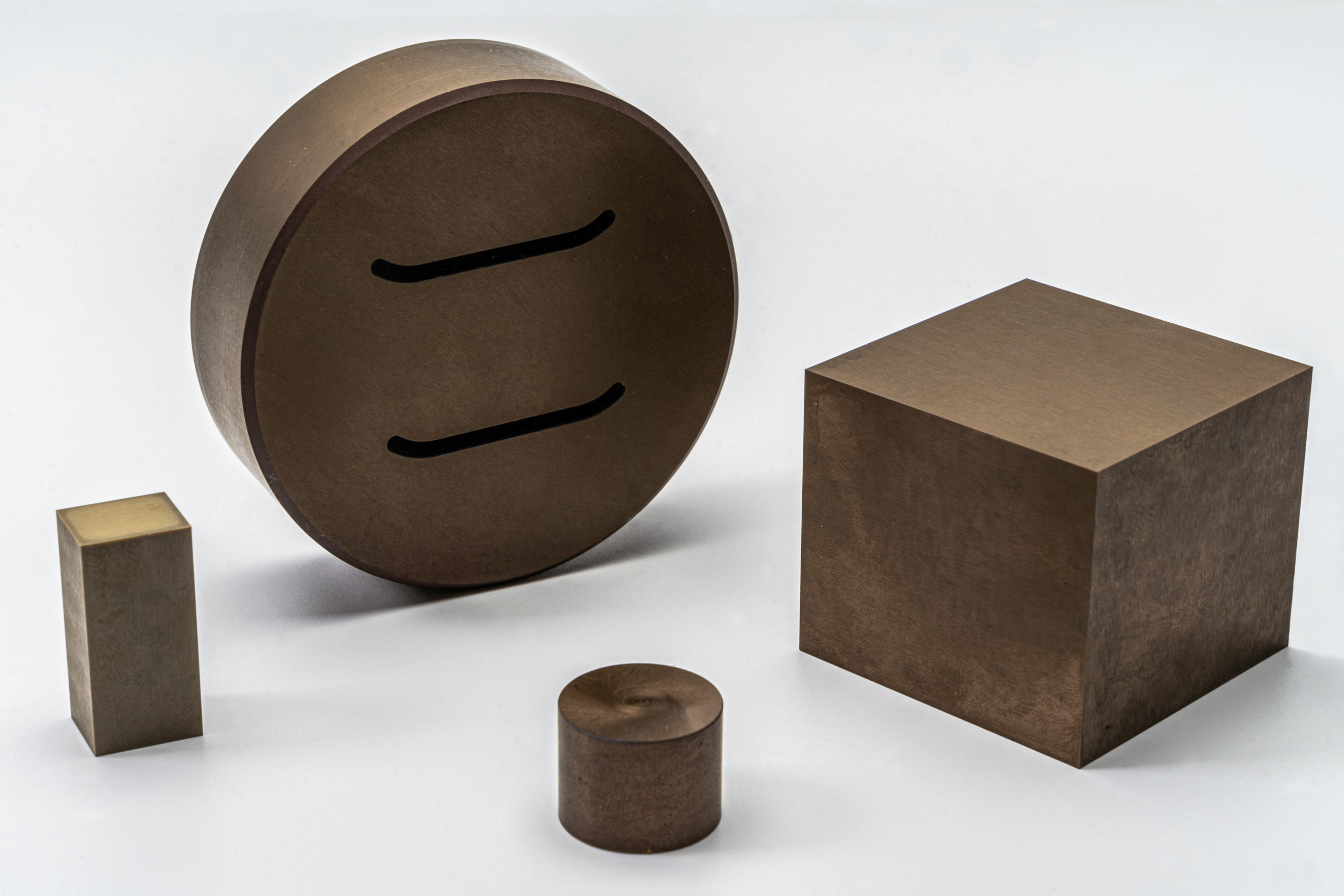

Exactly how technical ceramic materials outperform conventional materials in such a wide range of applications is academic. High quality raw materials are formed in the green state and sintered to create a finished component. Ceramic industry manufacturers can create an array of intricate profiles requiring minimal post-processing, thus preserving the exceptional qualities that place technical ceramics on the cutting-edge. View our technical ceramic products below:

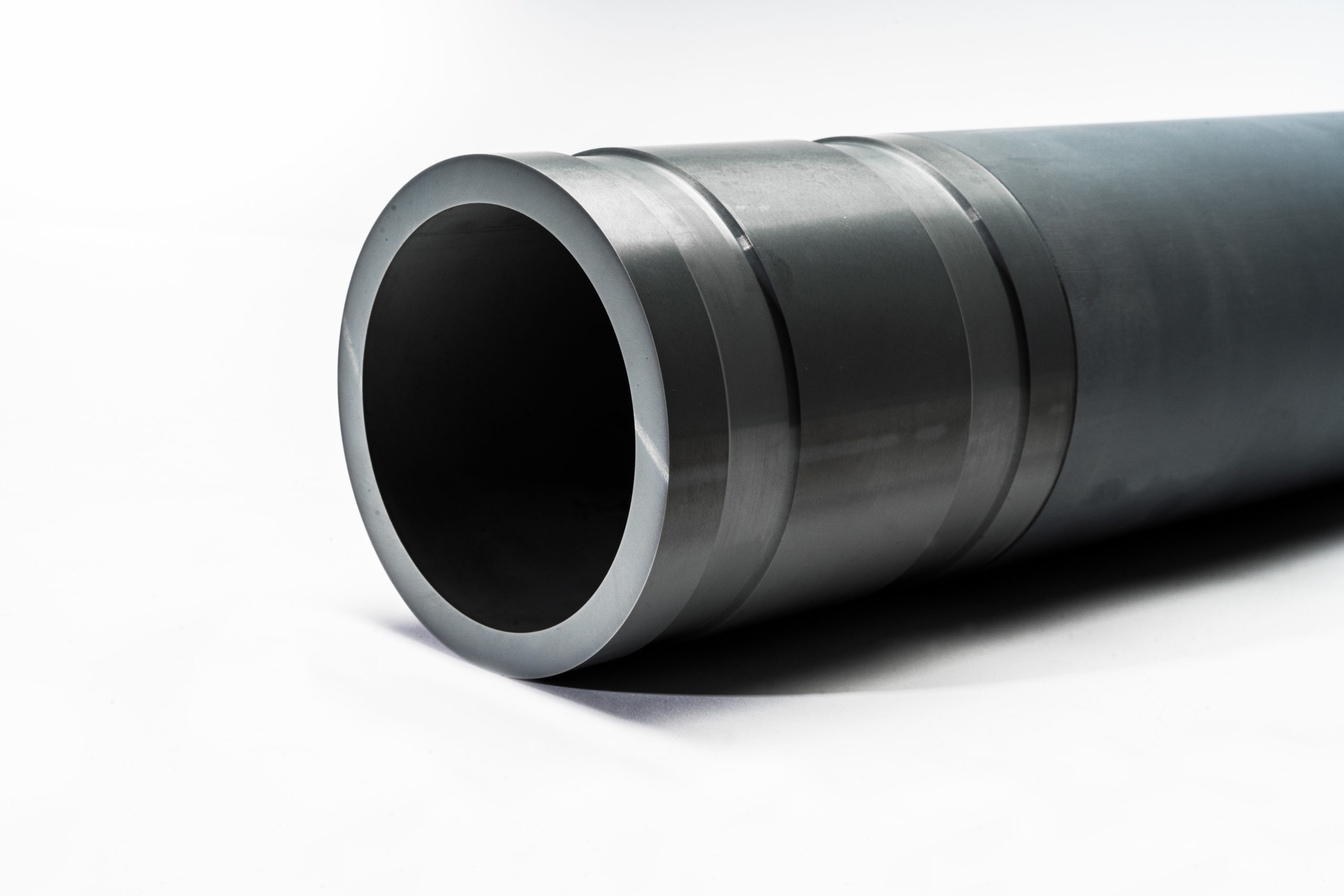

Thermocouple protection tubes

radiant and immersion heater tubes

high and low pressure riser tubes

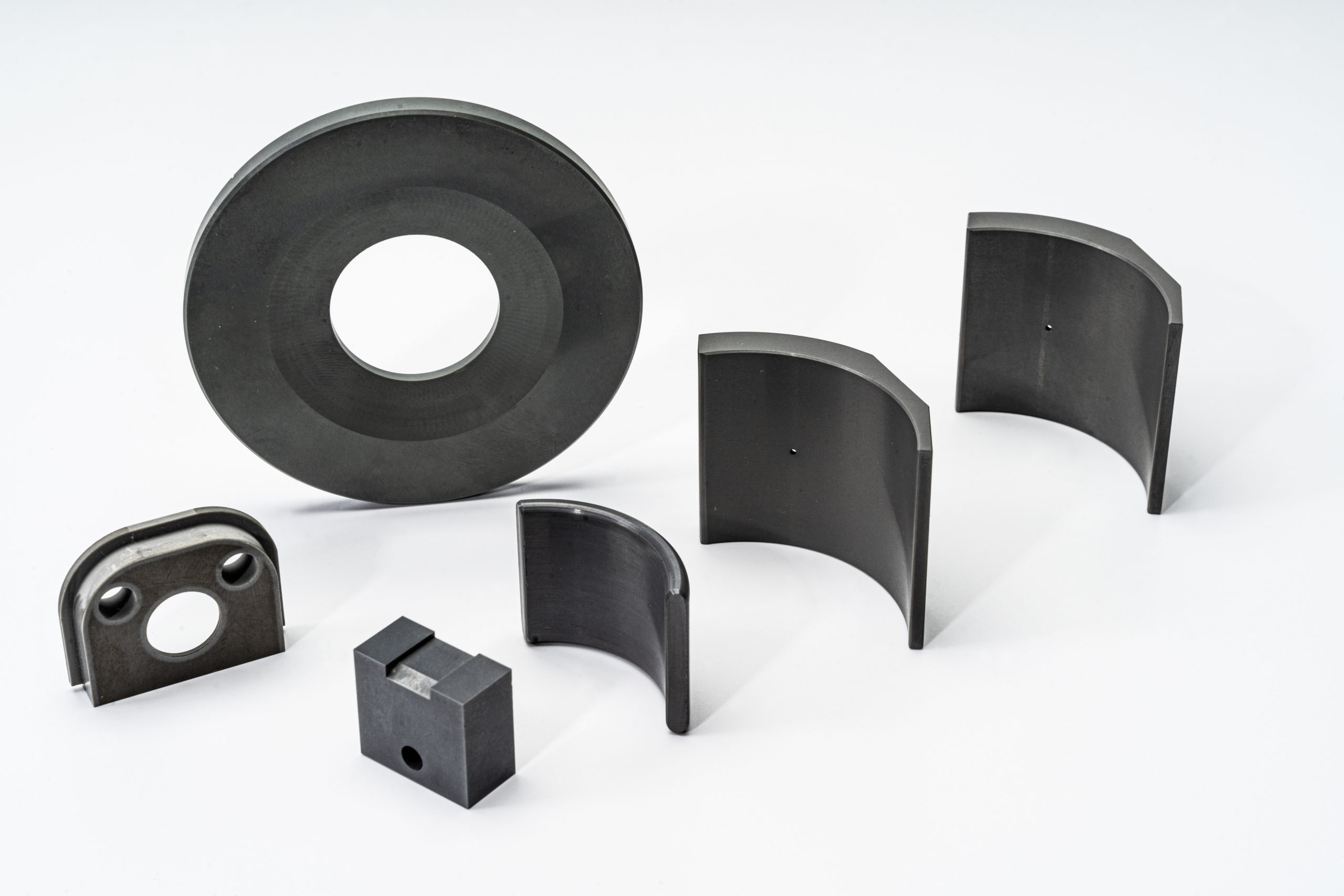

CRUCIBLES AND LADLES

weld location pins

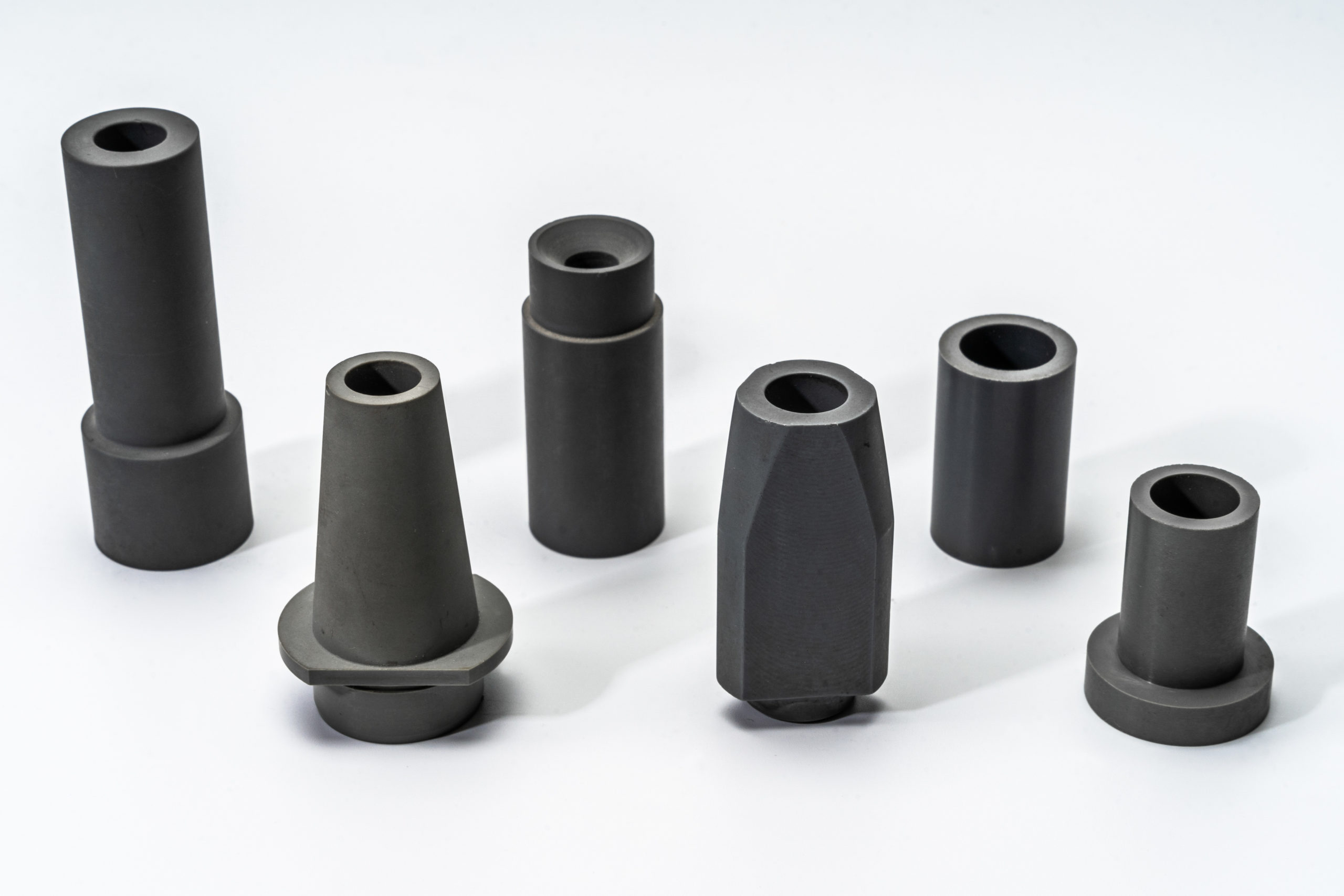

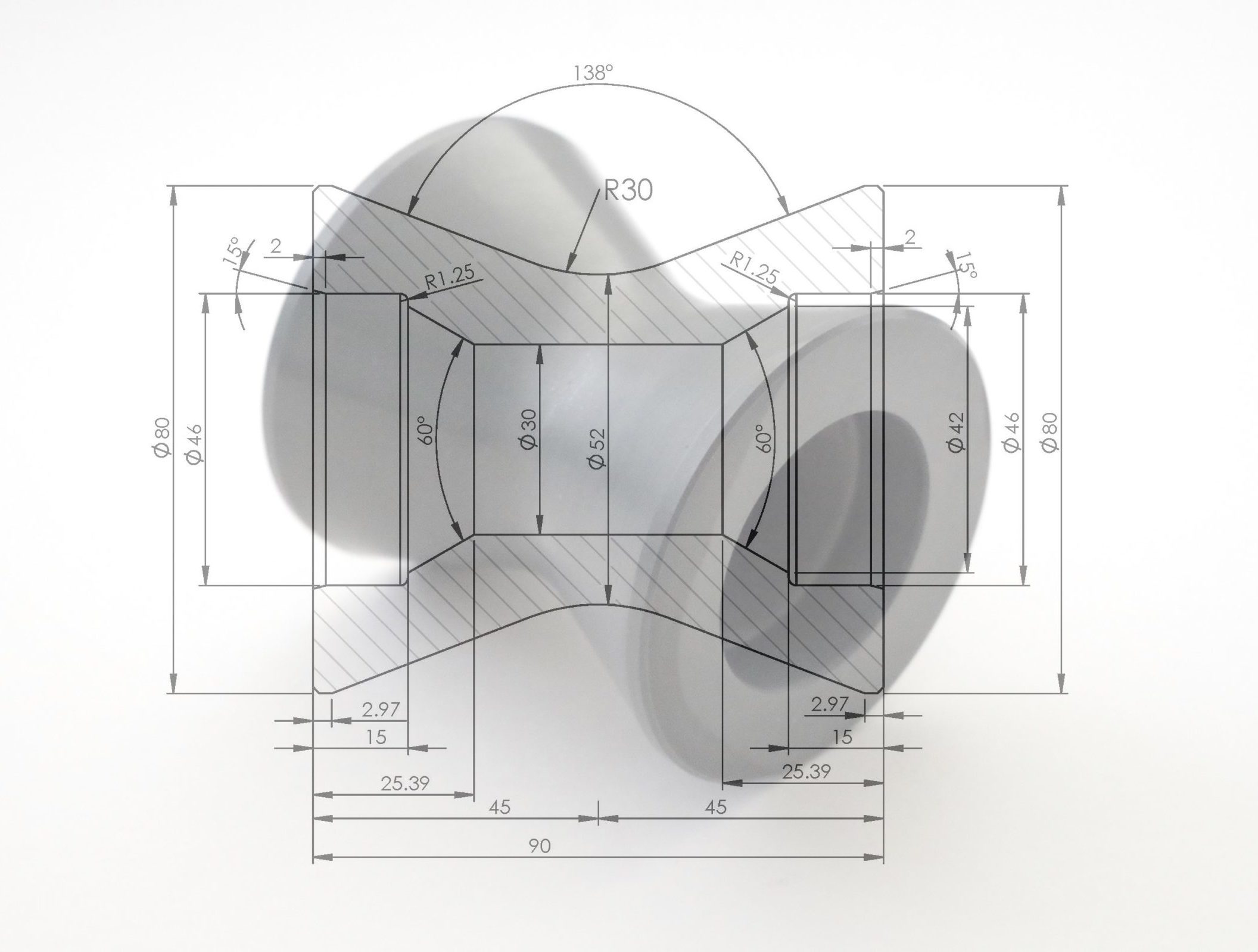

extrusion dies

weld rolls

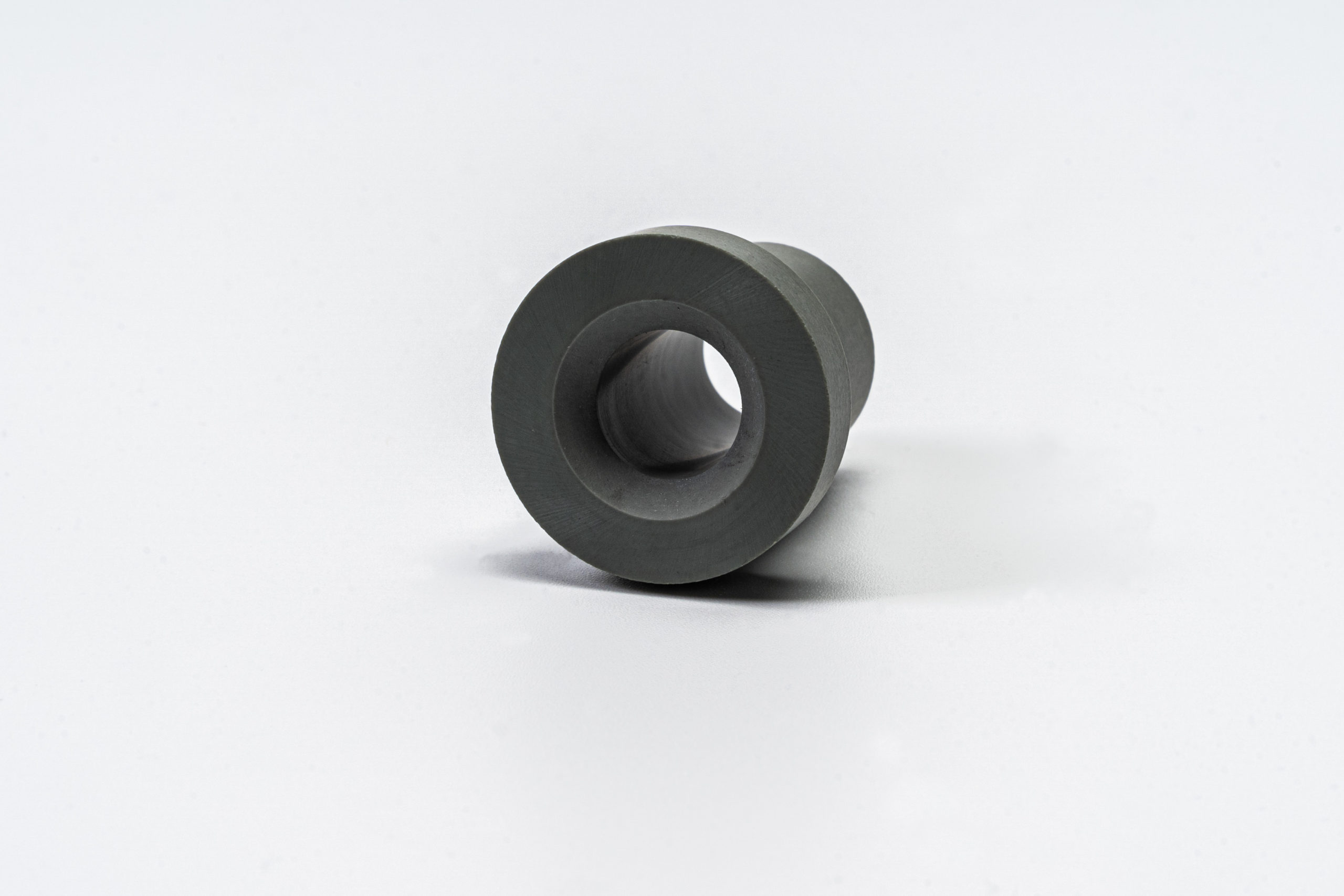

nozzles

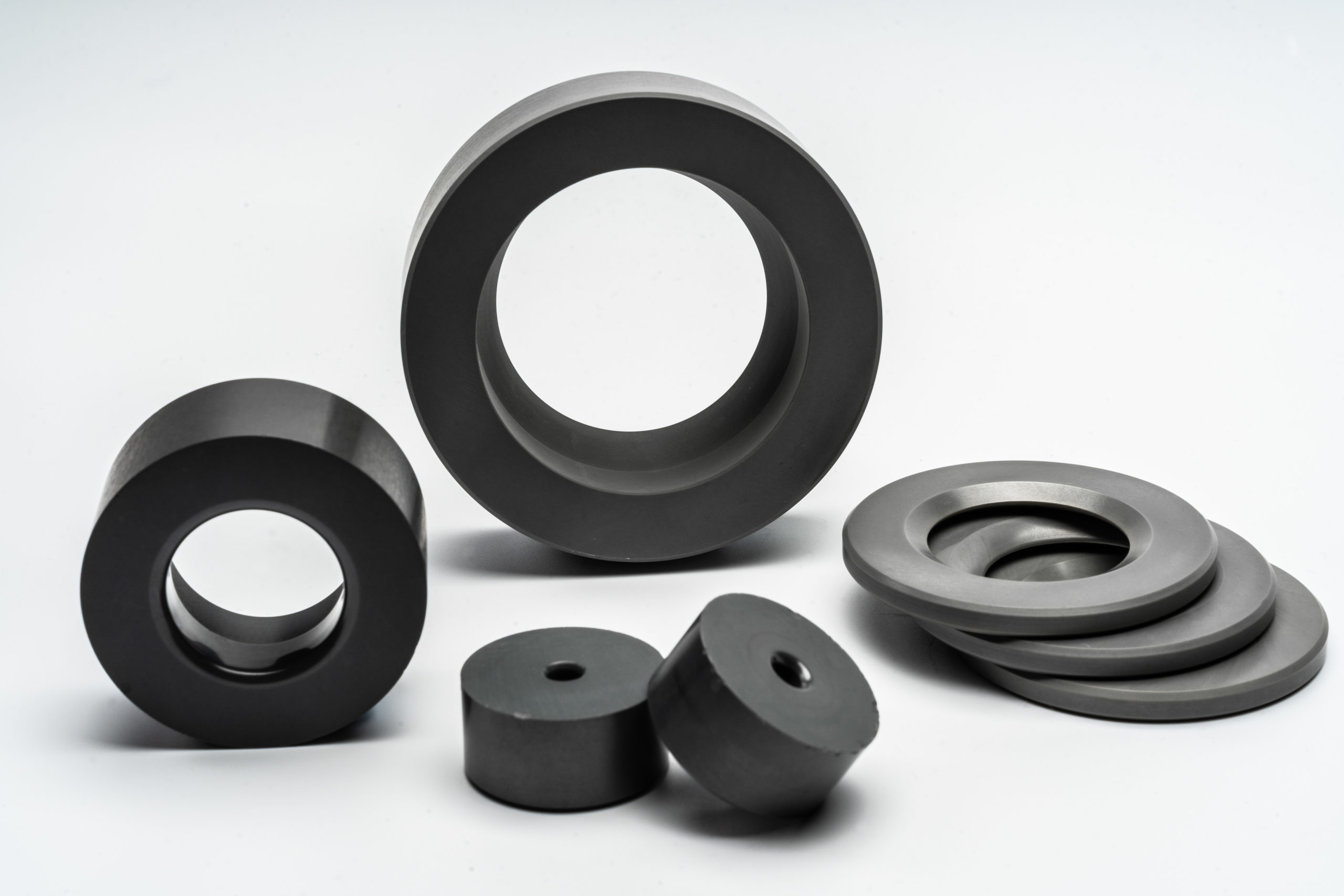

PLATES AND SEALS

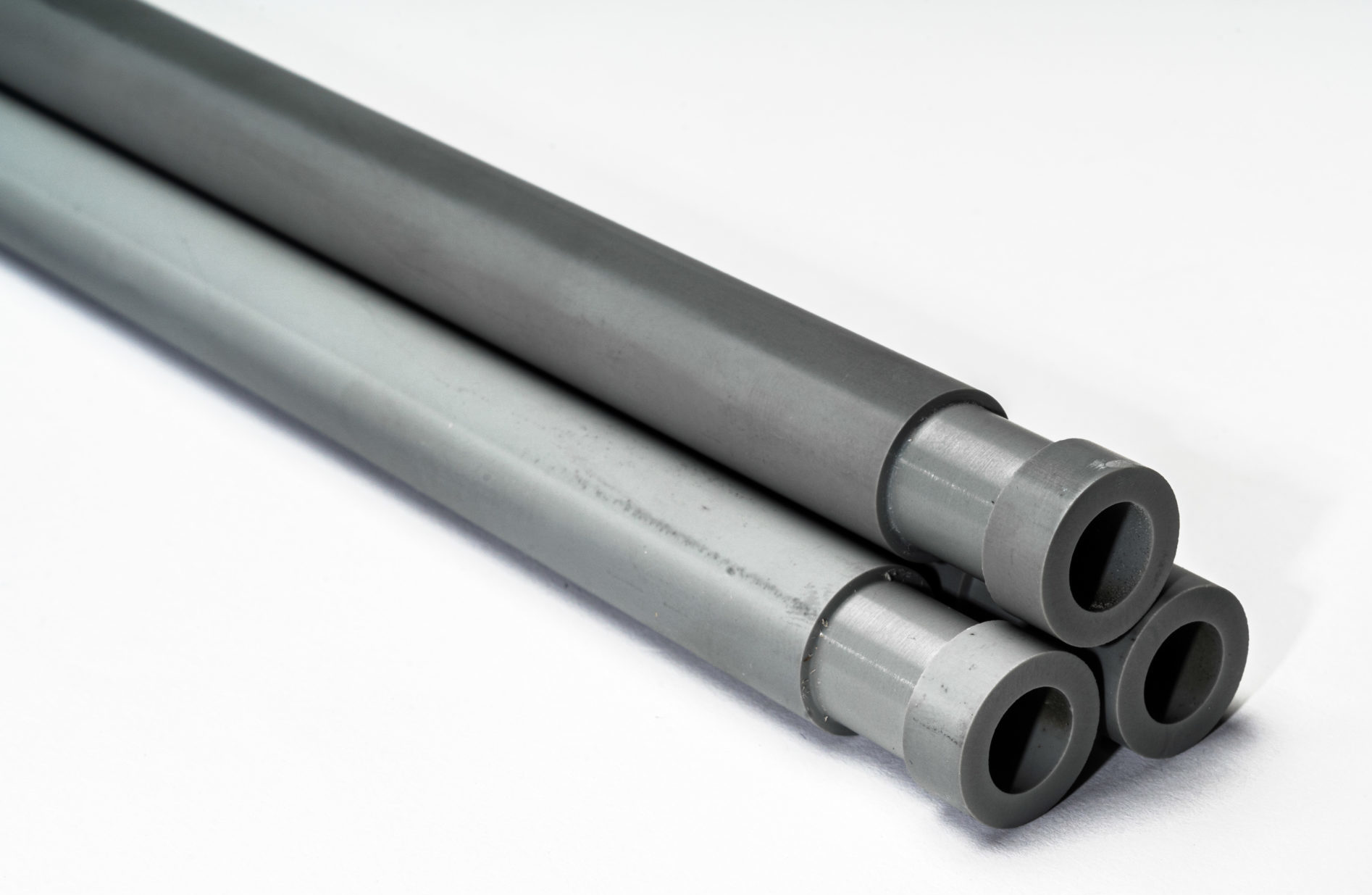

tubes and bushes

seats and liners

balls and milling media

electrically conductive ceramic

powders

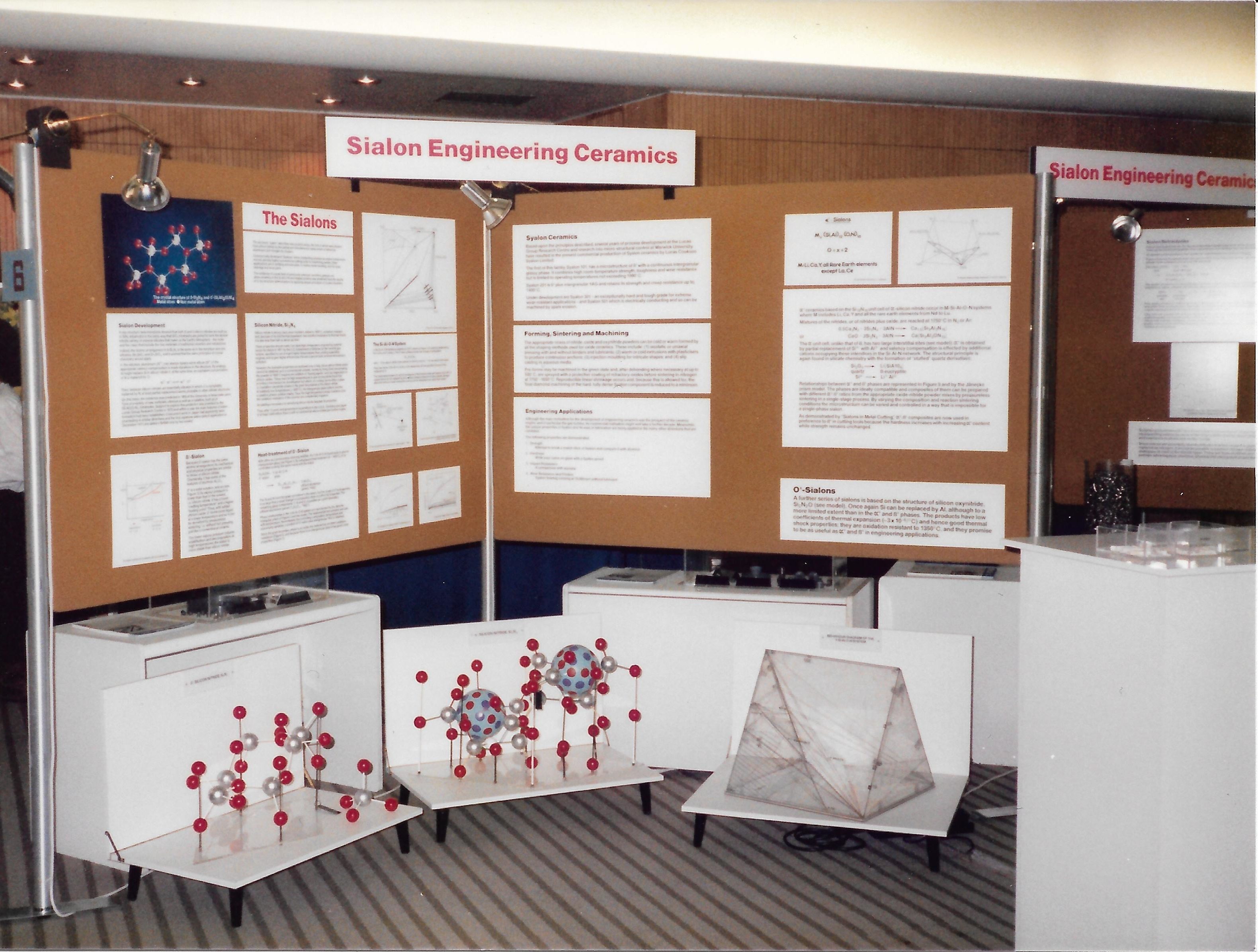

Explore the discovery of sialon ceramics

Learn how to design with ceramics

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.

Silicon nitride offers excellent corrosion and thermal resistance and are ideal materials for use in the chemical and process industries.