MECHANICAL SEALS AND PLATES

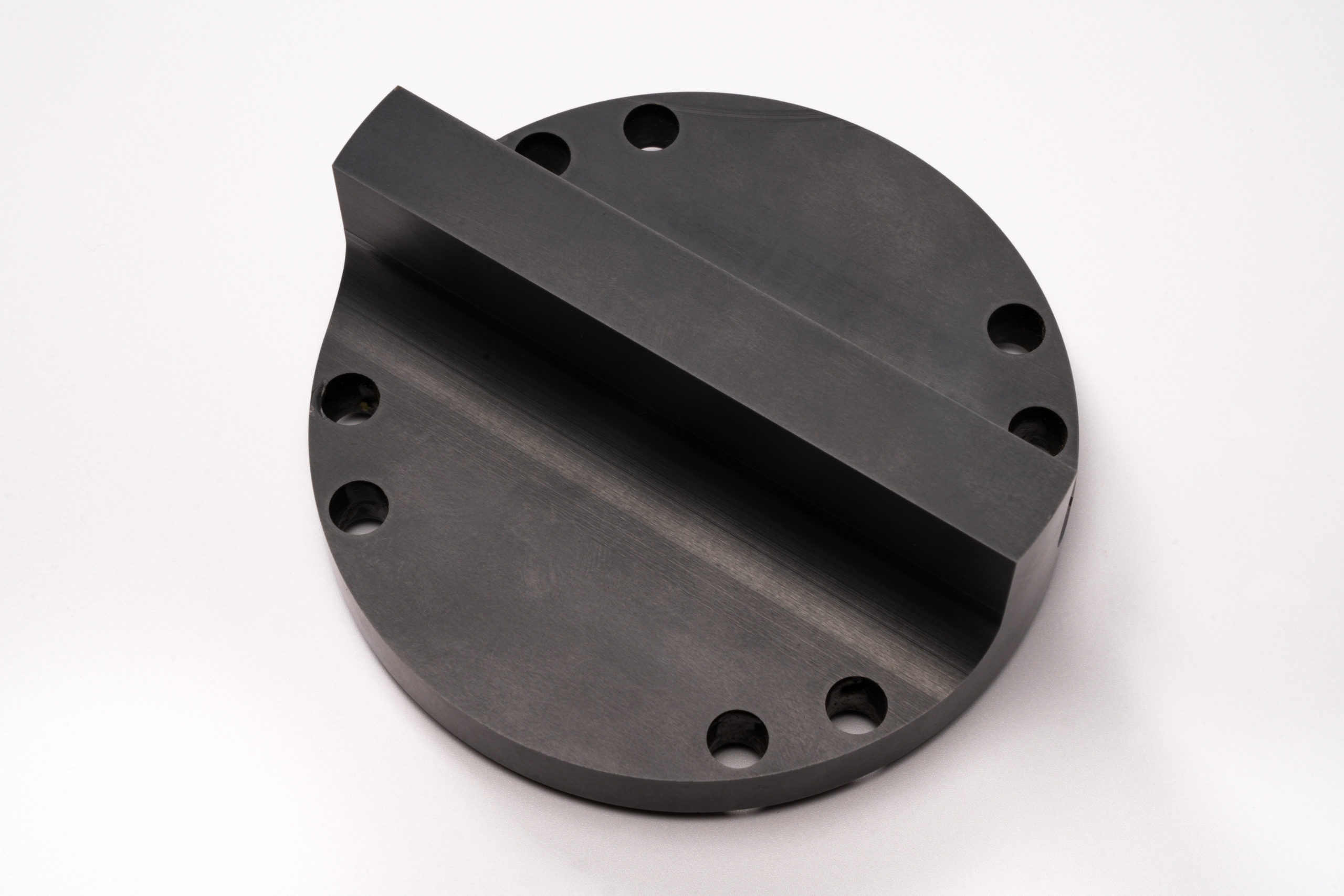

Plates and seals are crucial in safeguarding sensitive or fragile equipment – including electronics – from extreme temperatures, corrosive environments, or abrasive media. High-performance gaskets may be engineered from precision elastomers or corrosion-resistant steels, but ceramic materials are deployed when conventional systems will undoubtedly fail. Ceramic mechanical solutions generally take the form of faceplates, corrosion-resistant plates designed to create a physical barrier between sensitive systems and harsh environments.

Sialon, an advanced ceramic based on silicon nitride, is characterized by exceptional wear and corrosion-resistant properties. In many instances, Syalon 101 is an excellent choice for the hard faceplate or barrier material. Owing to its extreme hardness, high strength and toughness, and low coefficient of friction, Syalon 101 exhibits excellent wear resistance. This, combined with its outstanding chemical stability and superior thermal properties such as thermal shock resistance, makes it an ideal candidate material for many demanding sensor applications.

Syalon 050, a mixed α/β-sialon advanced ceramic, is designed to have extreme hardness and chemical and thermal stability, offering greater wear resistance and high strength.

In the Chemical and Process Industries (CPI), ceramic mechanical seals are integral components in equipment like pumps and compressors. For instance, in a pump, a rotating shaft can cause liquid leakage between the shaft and the pump casing. To prevent this leakage, a mechanical seal is used, which essentially consists of a hard material embedded in the casing and a softer material in the rotating shaft. These components are designed to be in intimate contact. The selection of seal materials is dependent on the material being pumped, its chemical reactivity, the temperature, and the pressure.

The successful integration of advanced technical ceramics into engineering systems necessitates close collaboration between you, the end user, and us, the material manufacturer.

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.

Silicon nitride offers excellent corrosion and thermal resistance and are ideal materials for use in the chemical and process industries.