CERAMIC WELD LOCATION PINS

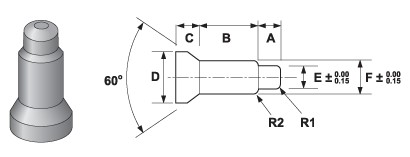

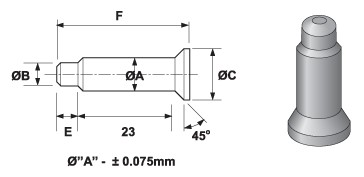

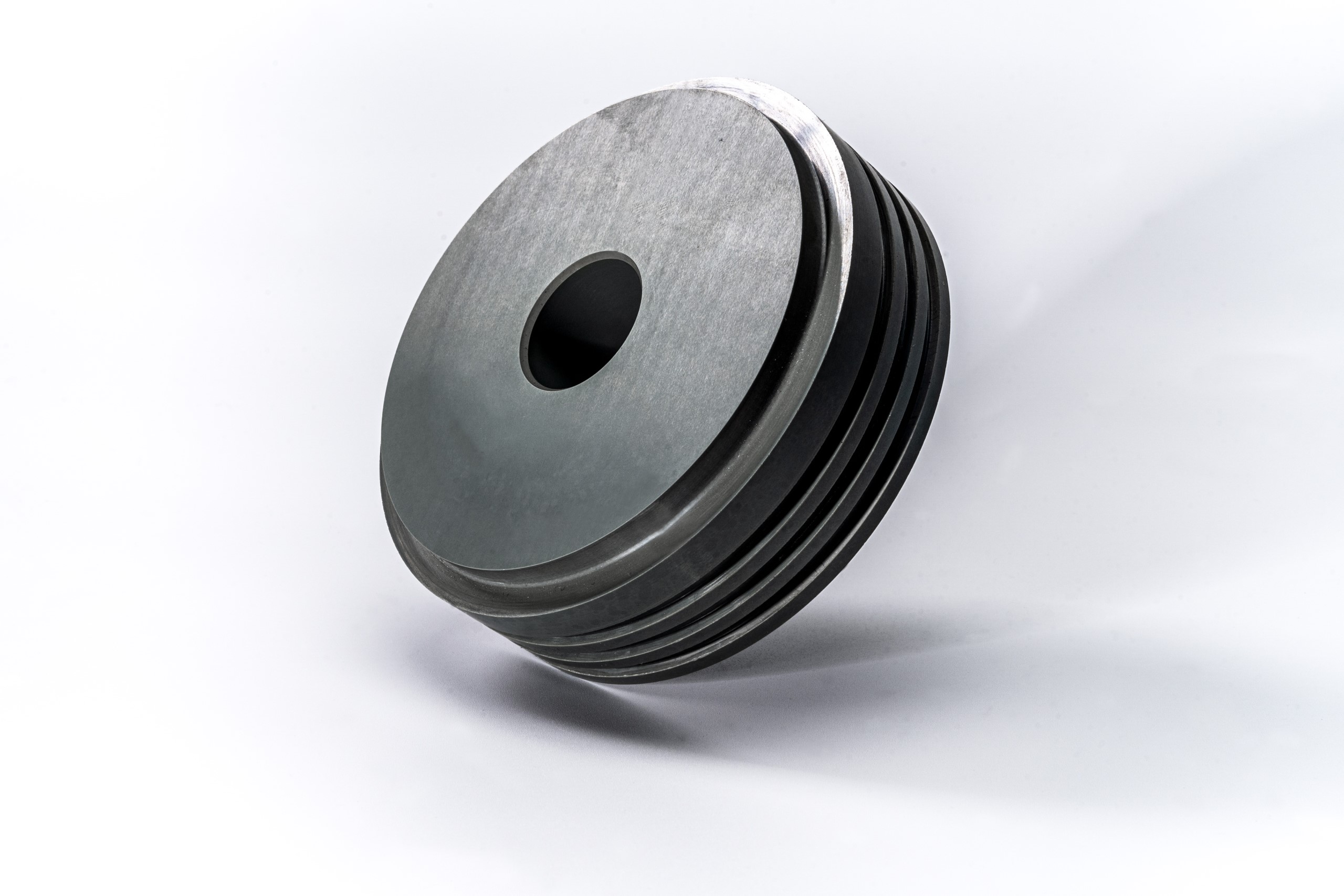

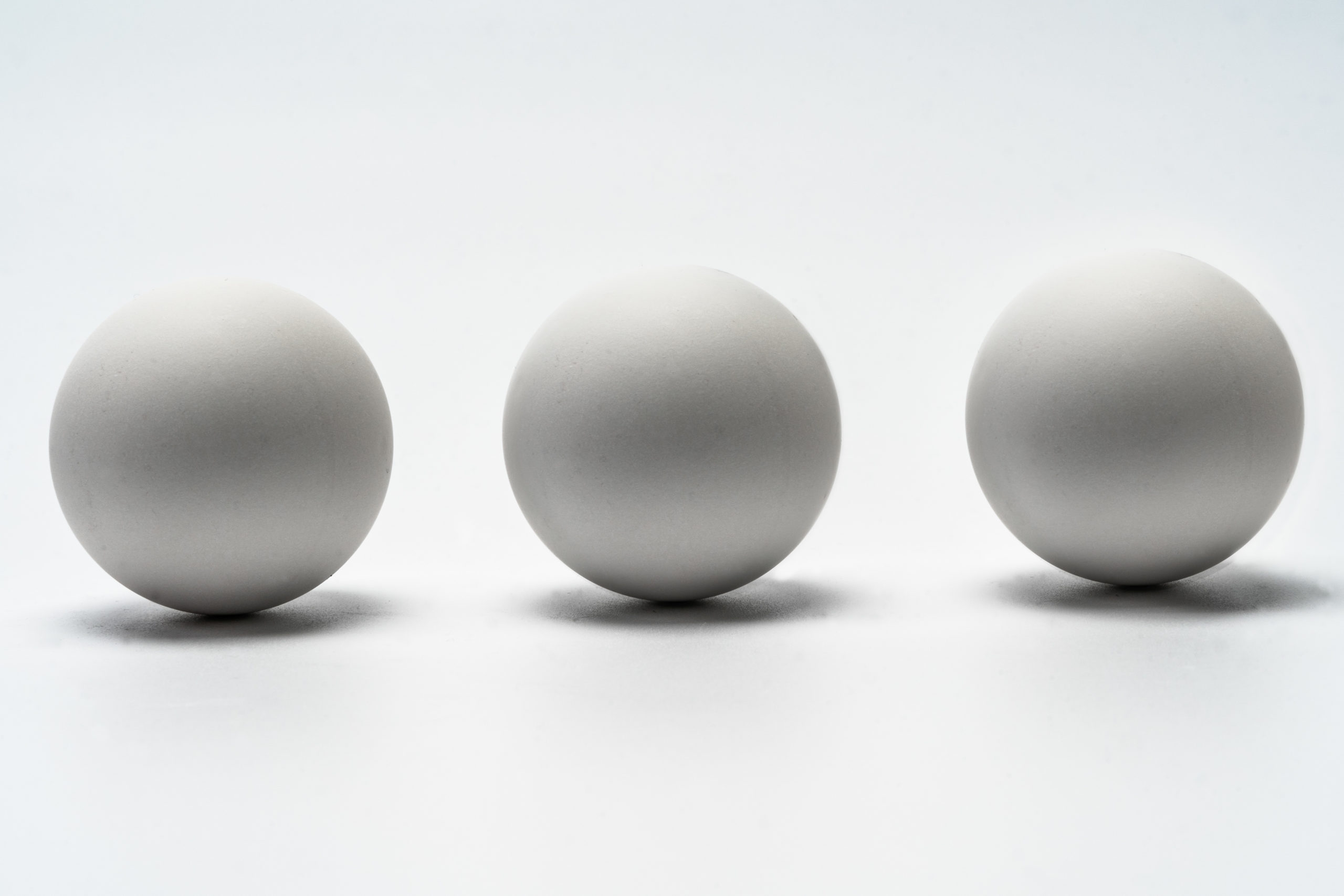

International Syalons manufacture a comprehensive range of silicon nitride, sialon and zirconia advanced ceramic weld location and control pins. These are used in the metal forming industry to allow precise welding of nuts to sheet metal.

Sialons are silicon nitride based ceramics which possess a number of characteristics, such as excellent mechanical, thermal and chemical properties, making them ideal in metal forming applications. Syalon 101 weld location pins have a proven history of success of more than 20 years by several leading automotive manufacturers.

Zircalon weld location pins are a more recent addition to our portfolio. They excel where their greater toughness is required, such as when severe impact is a possibility. Like Syalon 101 they have excellent wear resistance, however they are not recommended where thermal shock may occur. Also, they are double the weight of an equivalent Syalon101 weld pin. Zircalon is available in two grades, Zircalon 10 and Zircalon 30. Zircalon 30 has slightly superior properties for applications which demand it.

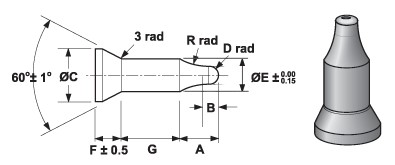

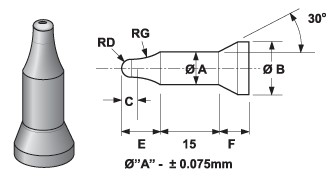

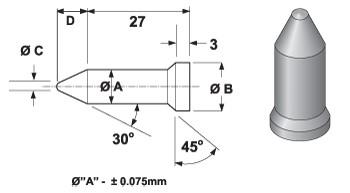

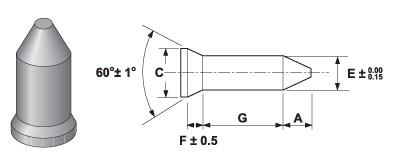

The tables below show our range of standard weld pins. However, we make a whole range of none standard sizes, so please contact us with your enquiry.

For details on using ceramic weld location pins, please download our User Guide.

Standard Sizes - Weld Location Pins

Download the Weld Location Pins Technical Sheet

Download the Weld Location Pins Technical Sheet

Download the Weld Location Pins Technical Sheet

Download the Weld Location Pins Technical Sheet

Download the Weld Location Pins Technical Sheet

Download the Weld Location Pins Technical Sheet

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Syalon 110 is silicon nitride-boron nitride composite, offering high temperature corrosion resistance in challenging molten metal handling applications.