ARTICLES AND GUIDES

This section of the website contains a number of articles giving more background information on International Syalons' range of advanced ceramics and how their properties and behaviour compare to competitive materials such as mullite and reaction bonded silicon nitride (RBSN). Also, there is a design guide giving advice on things to consider when using an advanced ceramic in your engineering design or application.

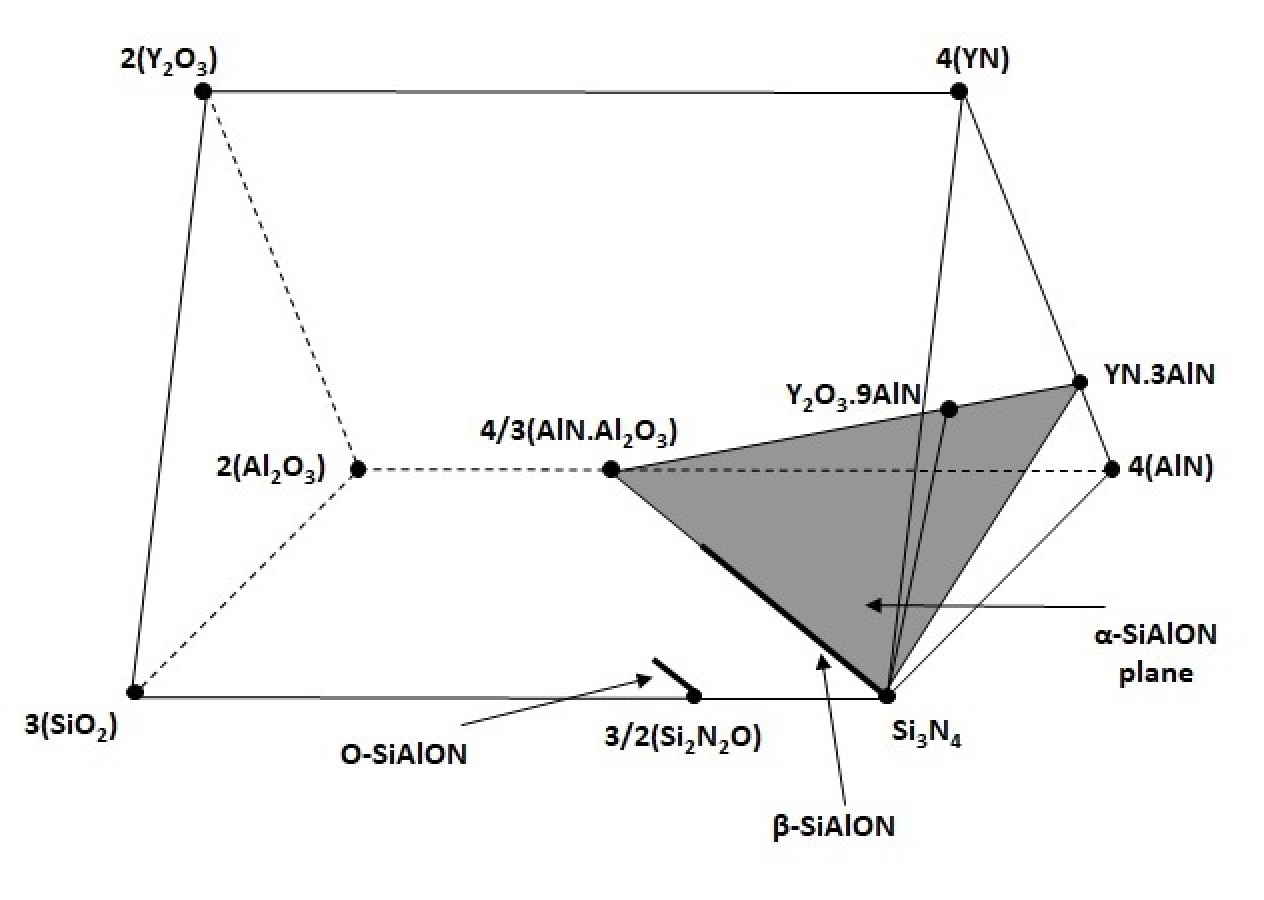

SiAlONs are ceramic alloys based on the elements silicon (Si), aluminium (Al), oxygen (O) and nitrogen (N) and were developed in the 1970s to solve the problem of silicon nitride (Si₃N₄) being difficult to fabricate. As alloys of Si₃N₄, SiAlONs exist in three basic forms. Each form is isostructural with one of the two common forms of Si₃N₄, beta (β) and alpha (α) and with silicon oxynitride.

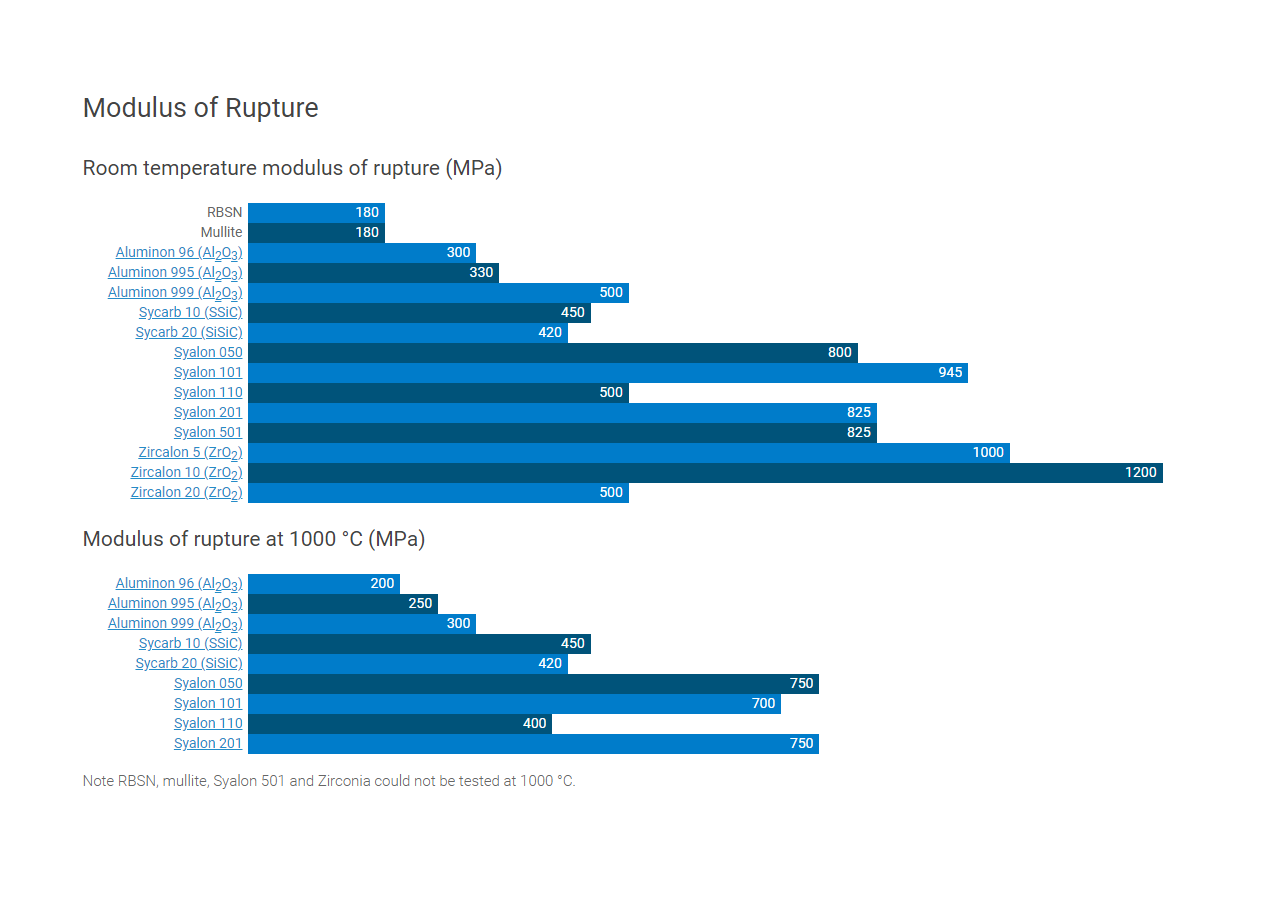

As modern industry continues to demand stronger, harder, more wear resistant and heat resistant materials, which will operate cost effectively in hostile environments, it has become essential to seek alternative engineering materials...

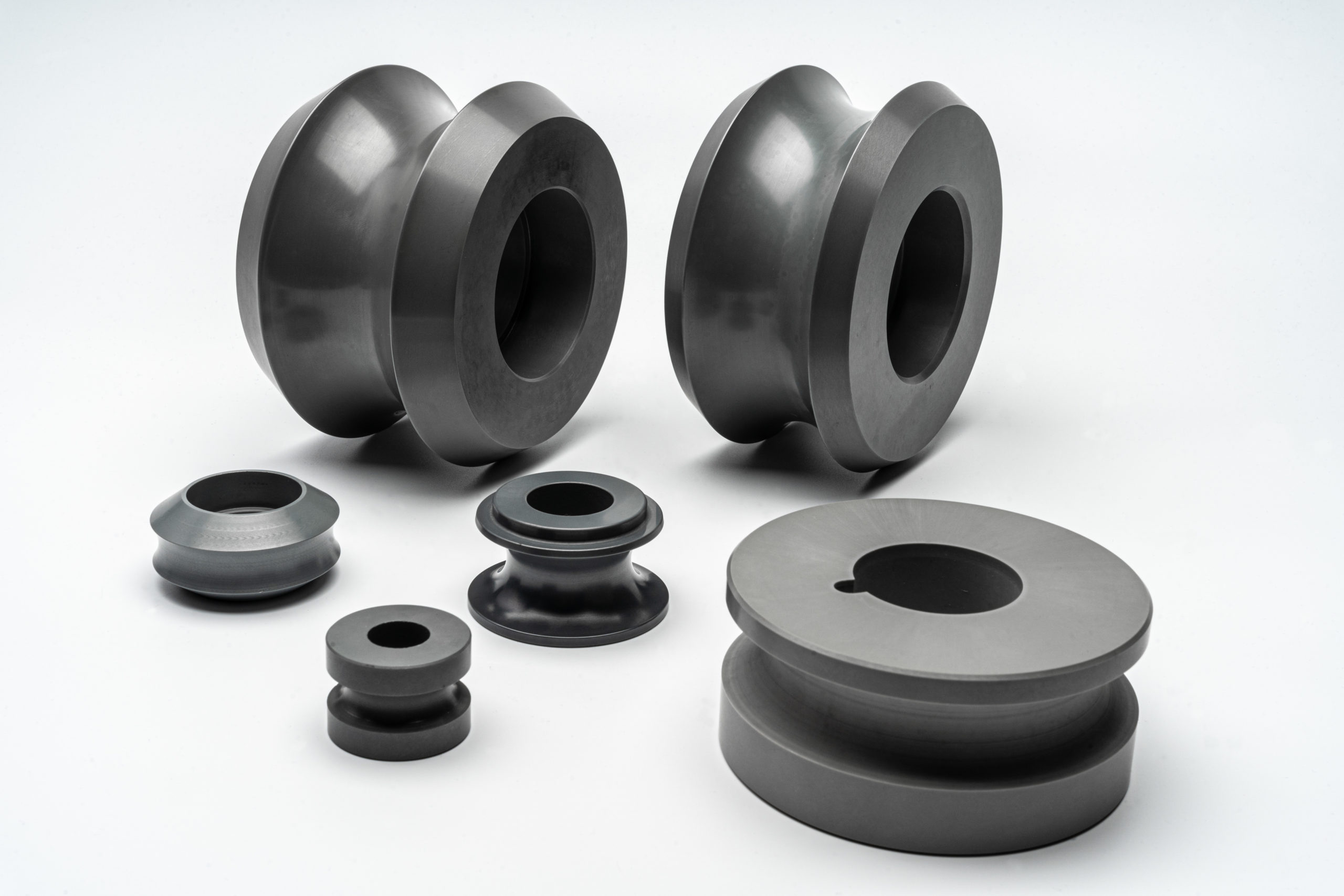

International Syalons offer a range of silicon nitride based sialon, alumina, zirconia and silicon carbide advanced ceramics. These materials will potentially meet your needs in many testing industrial and engineering environments...

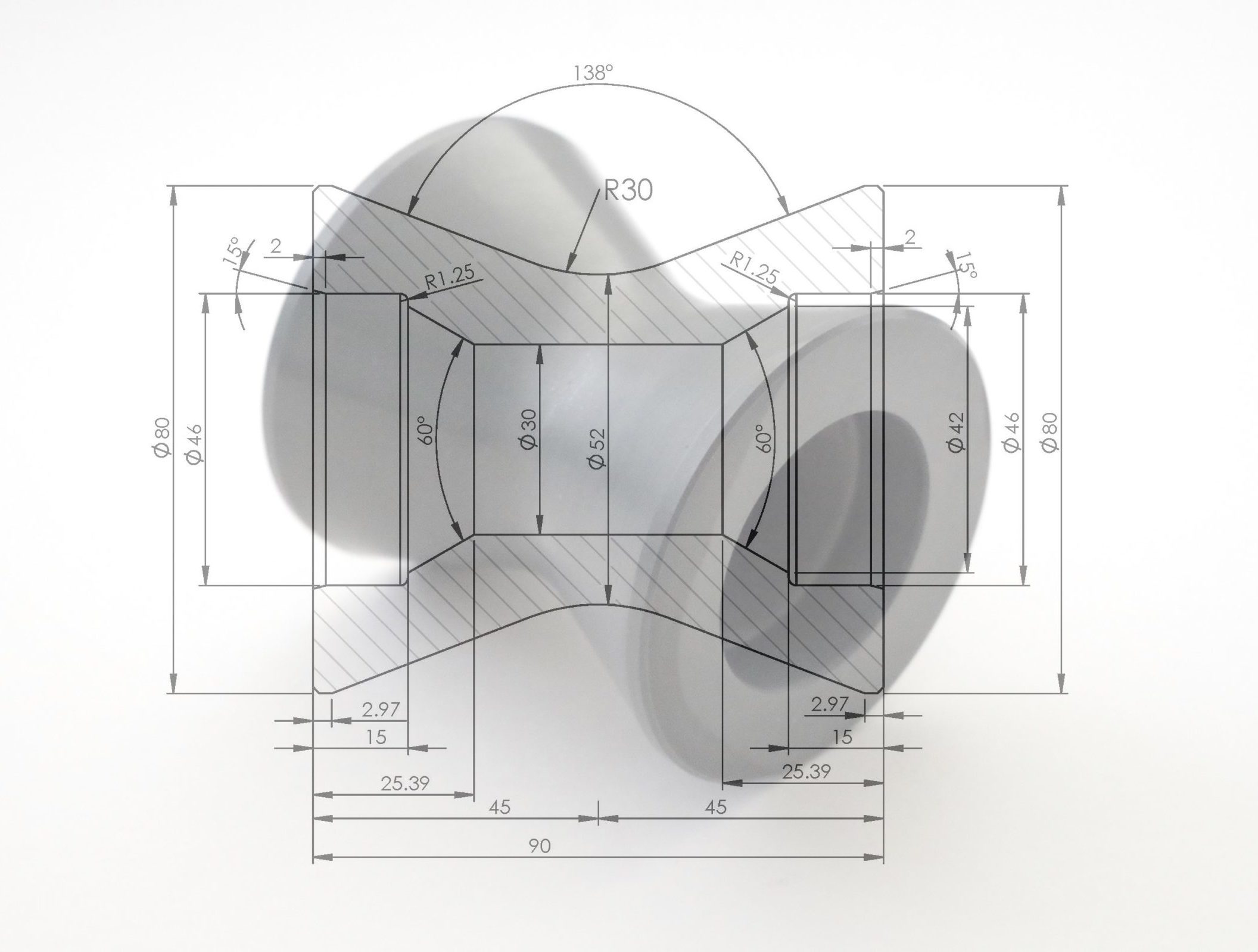

Often an engineer unfamiliar with using ceramics will want a direct copy of a component that was originally metal, for example, made in ceramic. Very often this is not the best solution and can unnecessarily increase manufacturing costs and even result in the component not working as desired...

Silicon nitride (Si₃N₄) was discovered in the mid-nineteenth century and caused no excitement among the engineering fraternity of the day. The problem was that Si₃N₄ does not lend itself to ease of fabrication...

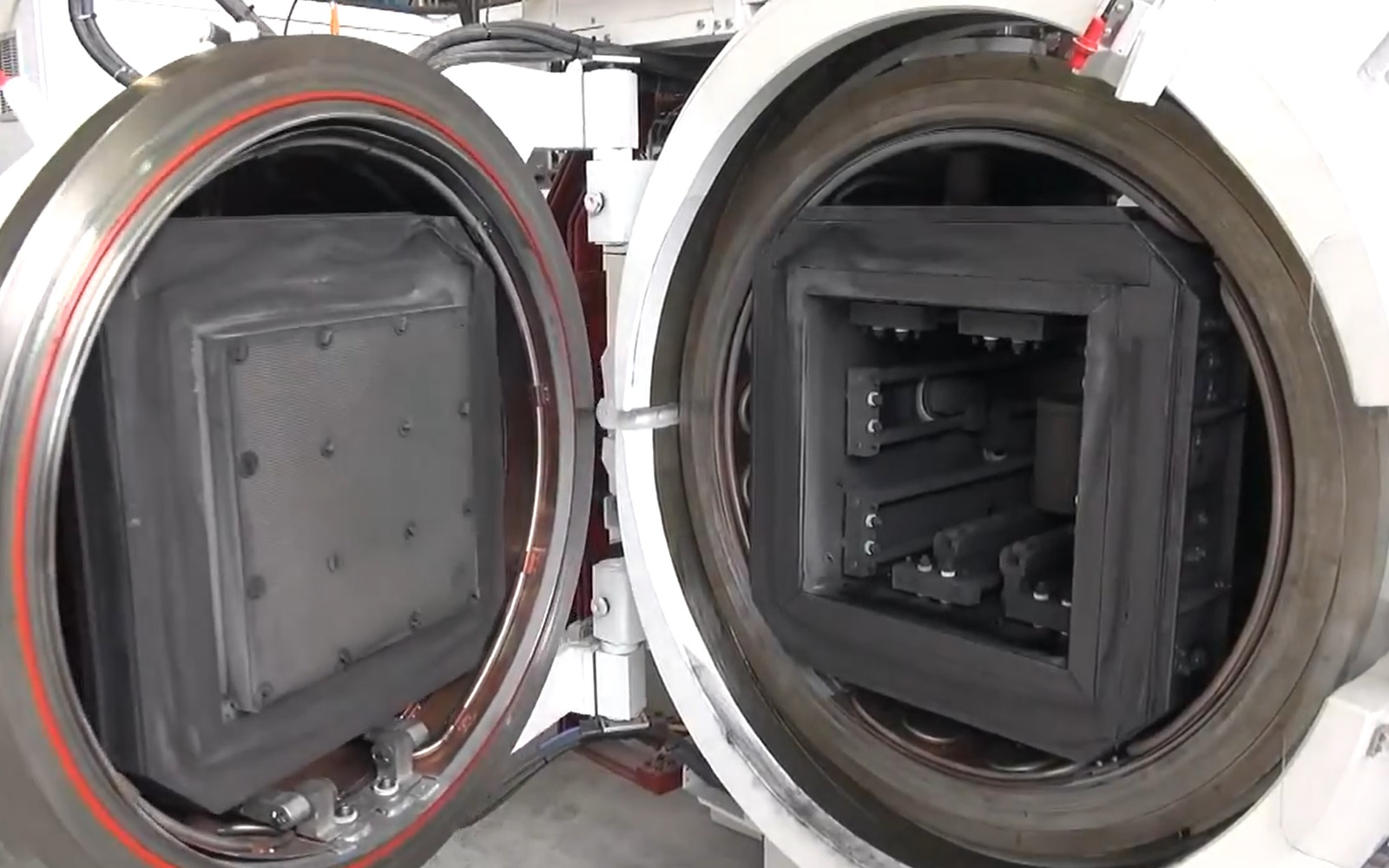

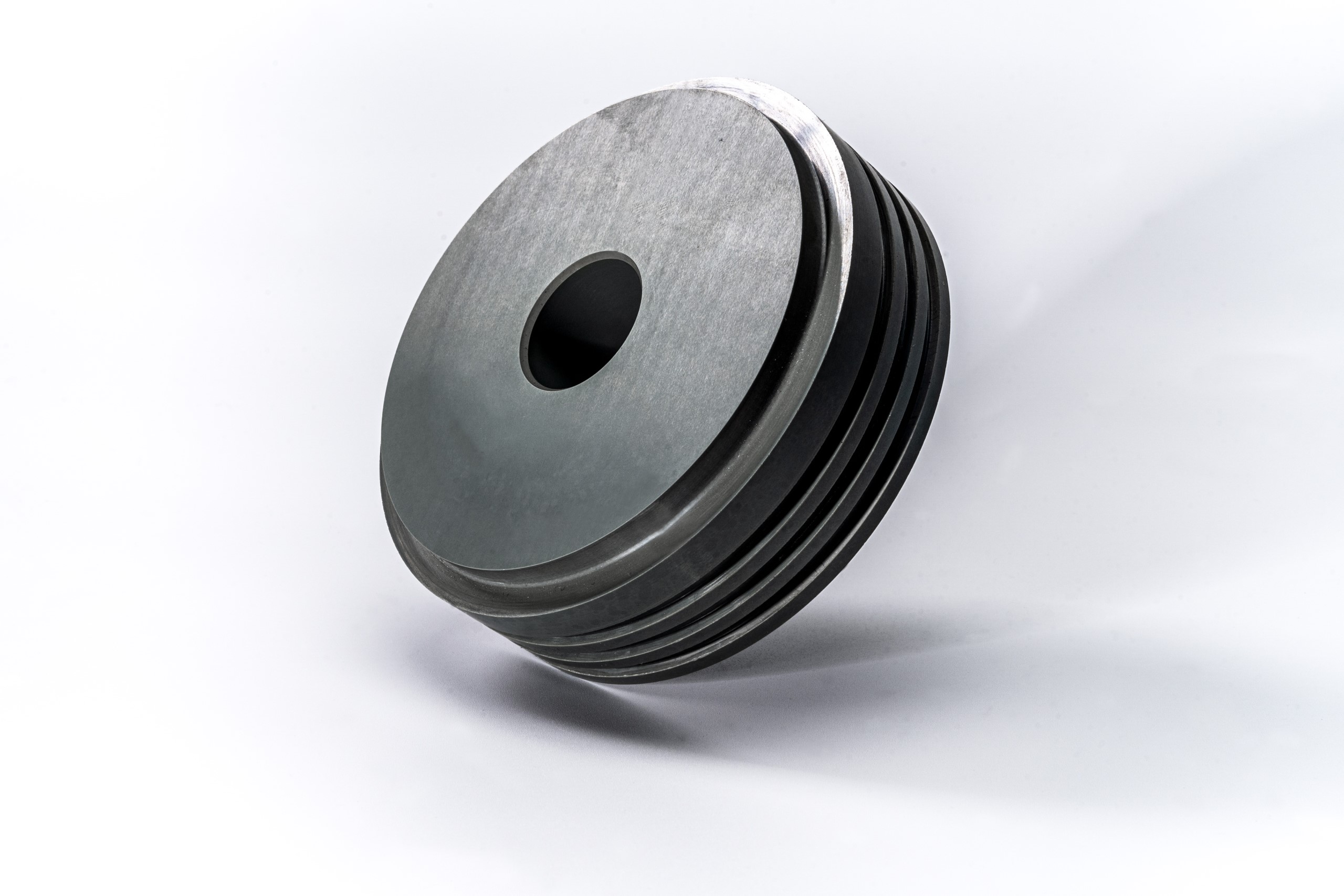

The process of manufacturing advanced ceramics such as silicon nitride and sialon, alumina, zirconia, and sintered silicon carbide can be summarised in the following steps: raw material processes, forming processes, sintering, diamond grinding (optional), and inspection...

Silicon nitrides (Si₃N₄) are a range of advanced engineering ceramics characterised by high strength, toughness and hardness and excellent chemical and thermal stability. Silicon nitride does not lend itself to ease of fabrication, due to its covalently bonded nature...

Ceramic solutions for the most challenging applications

Browse our brochures, technical guides, and data sheets

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Zircalon 30 is a co-stabilised zirconia-based ceramic with an alumina matrix, which is reinforced by self-grown alumina-based platelets and offers outstanding fracture toughness.