High-strength ceramics serve some of the most demanding applications on—and off—earth. These advanced materials, like sialons, are among the strongest mankind has ever engineered and are theoretically capable of withstanding tremendous forces. Why, then, does reality often fall short? Even when performing above user expectations, some ceramics fail to live up to their own promise. This doesn’t generally represent a technical concern, given that engineering ceramics’ real-world performance often eclipses that of traditional materials by orders of magnitude. Yet it could serve as a barrier to future innovation and truly astronomical efficiency gains. Let’s explore why ceramics may fall short of their theoretical strength and what’s being done to bridge the gap.

Choosing the Right Wire and Cable Guides: Comparing Ceramic, Tool Steel, and Carbide Materials

When selecting the right wire and cable guides, choosing the best material is crucial for maximizing efficiency, reducing maintenance costs, and ensuring long-lasting performance. Three common materials—ceramic, tool steel, and carbide—each offer distinct advantages and limitations in this context. Let’s compare them in detail, highlighting why ceramic materials are often the superior choice, particularly in challenging high-wear environments

Essential Considerations When Choosing the Right Technical Ceramics Manufacturer

Selecting the right technical ceramics manufacturer is a critical decision that impacts the performance and durability of products across industries such as aerospace, automotive, and molten metal handling. The right partner will ensure that your components perform reliably in extreme conditions—whether it’s resisting high temperatures, withstanding corrosive environments, or enduring heavy wear.

Enhancing Wire and Cable Production with Sialons

Drawing metal wire through dies generates intense friction as coating and extruding cable exposes tools to high heat. These tough conditions challenge wire and cable manufacturers, who must optimise for efficiency without sacrificing equipment durability. Sialons, a specialized class of technical ceramics derived from silicon nitride, provide a solution. Their remarkable resistance to wear, heat, and corrosion helps extend tool life, boosting performance and reducing downtime across production lines.

Top 10 Applications of Zirconia Ceramic in Modern Industries

Zirconium dioxide (ZrO2), or zirconia, has a rich history of diverse applications. This is courtesy of the material’s many strengths, including its aesthetic qualities. Gemstones derived from zircon were prized in ancient Egyptian jewellery, and though the material generally finds more practical applications today, cubic zirconia remains the most popular diamond simulant on the market. At the other end of the spectrum—as far as functionality is concerned—zirconium alloy tubing is ubiquitous in nuclear power stations, as it boasts extremely low neutron capture. In fact, more than 90% of mined zirconium is deployed in fission reactors.

And, still, there are many more applications of zirconia ceramics to explore.

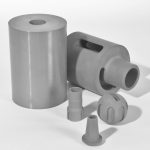

Manufacturing Process of Ceramic Products: A Guide for Materials Engineers

Engineers increasingly turn to technical ceramics for demanding applications where traditional materials fall short. These materials offer an outstanding combination of high hardness, superior wear resistance, and robust thermal stability, maintaining their integrity under extreme temperatures and corrosive environments. Whether for aerospace components, cutting tools, or molten metal components, their unique properties make them indispensable. Their low mass compared to metals further enhances performance by providing strength without excessive weight, making them an ideal choice for advanced engineering solutions.

How to Prototype and Test Ceramic Solutions for Abrasive Conditions

Prototyping is inherently concerned with meticulous material selection. It concerns the rigorous, multi-step process of generating the right tool for a job. This can be complex even for relatively forgiving conditions. But there is very little margin for error in wear applications. Poor material selection can have severe deleterious effects on operations with abrasive environments. It’s essential to choose materials that can withstand the dynamic stresses of the intended application. However, there is no one-size-fits-all solution in the world of prototyping.

Continue readingIs Brittleness an Issue for Ceramic Parts in Flow Systems?

Pipes, valves, and other flow components must withstand significant thermomechanical stresses, plus chemical exposure throughout service. But these factors are far from constant. Sharp temperature variations can induce brittleness. Abrupt mechanical stress can allow microcracks to propagate. Over time, these issues can precipitate microstructural changes that increase a material’s tendency to break under stress.

Continue readingSilicon Carbide Vs Tungsten Carbide in Wear Applications

How do you decide between one engineering material and another? Cost is often one of the main influencers, but it is impossible to fully characterise integration and maintenance costs without fully understanding the material’s time-dependent performance under service conditions. Continue reading

Which Engineering Materials to Choose When Stainless Steel Fails

Stainless steel is an extremely popular engineering material, but it is not without flaws. The characteristic corrosion resistance of stainless grades will diminish under certain challenging conditions. Corrosion, erosion, and oxidation are not only possible but likely in the presence of harsh chemicals, extreme temperatures, and abrasive media. These factors contribute to performance and structural losses over time. Fortunately, there is a wealth of alternatives to choose from. Continue reading