International Syalons (Newcastle) Ltd. offices will be closed from Friday 21st December until Thursday 3rd January.

Molten Aluminium Degassing using Sialon

Molten aluminium (Al) is an extremely reactive substance. The molten metal is so reactive that it will readily decompose water in the atmosphere, or moisture on wet tools, releasing hydrogen into the melt. Even small volumes of water condensing on a crucible furnace or transfer ladle can affect the quality of final castings. Excess hydrogen can affect the distribution of porosity, and the total amount of shrinkage, ultimately increasing scrappage. Eliminating gas absorption from molten aluminium is unfeasible. So, metallurgists tend to focus on preventing hydrogen introduction into the melt and removing as much as possible prior to casting.

The Story of Ceramics in the UK

Ceramics are still widely associated with the elegant yet brittle shapes of traditional manufacturing, despite the astronomic strides that materials scientists and engineers have made over the last two and a half centuries. This is primarily due to the schism between commercial and technical ceramic materials. Retail ceramics retain a flair for aesthetics over functionality, which has roots in Romantic-era pottery and ancient porcelain. These products retain that traditional sense of style and continue to dominate the general public’s perception of what ceramics are capable of.Continue reading

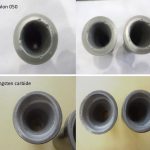

Advanced Engineering: Syalon 050 vs Tungsten Carbide Blast Nozzles

A car engine block can weigh anything from 90 kilograms (kg) to over half a tonne without its associated parts, such as the power train or other directly connected components. The weight of the vehicle is one of the defining factors in its overall performance and efficiency, and reducing the weight profiles of integral components has been an ongoing challenge for advanced engineering of modern vehicles.

Continue readingInsight into the Hardness of Silicon Nitride

At International Syalons, we have explored the mechanical properties of silicon nitride (Si3N4) at great length. Silicon nitride is an advanced engineering ceramic that circumvents many of the conventional drawbacks of numerous oxide ceramics. Outstanding fracture toughness and high moduli of both rupture and elasticity impart excellent resistance to multiple wearing phenomena. This enables silicon nitride-based ceramics to withstand severe operating conditions that may cause comparatively brittle ceramics to propagate flaws, deform, or fail.Continue reading

The Fracture Toughness of Ceramic Materials

High strength ceramic materials are pervasively utilized in demanding industrial applications, owing to their unique thermomechanical characteristics. Typically, advanced ceramics exhibit tightly-bound granular structures with extremely dense microstructural arrangements. This imparts varying levels of material strength and resistance to chemical attack, depending on the distinct chemical makeup of the ceramic.

Continue readingHigh strength ceramic materials are pervasively utilized in demanding industrial applications, owing to their unique thermomechanical characteristics. Typically, advanced ceramics exhibit tightly-bound granular structures with extremely dense microstructural arrangements. This imparts varying levels of material strength and resistance to chemical attack, depending on the distinct chemical makeup of the ceramic.

Continue readingExploring the Ultra-High Temperature Strength of Sialon Technical Ceramics

Updated: Originally published on 25/10/2018

Silicon nitride (Si3N4) ceramics have outstanding thermal shock resistance and ultra-high temperature strength values, exceeding many technical ceramics in terms of their resistance to thermodynamic stress. The main challenge associated with manufacturing silicon nitride for industrial applications is of cost-effectively achieving full densification of green bodies. Hot pressing methods yield fully dense, high-performance technical ceramics but at excessive costs.

Continue readingThe Electrical Properties of Si3N4

Silicon nitride (Si3N4) is one of the most advanced engineering ceramics on the market, providing an outstanding blend of mechanical and thermal properties. Each individual member of the Si3N4 ceramic family is comprised of silicon (Si) and nitrogen (N) in a densely-packed atomic arrangement of high-strength intra-structural covalent bonds. This provides the basis for the material’s high thermal and mechanical performance, as well as interesting electrical properties which can be tailored to specific applications.

Continue readingSilicon nitride (Si3N4) is one of the most advanced engineering ceramics on the market, providing an outstanding blend of mechanical and thermal properties. Each individual member of the Si3N4 ceramic family is comprised of silicon (Si) and nitrogen (N) in a densely-packed atomic arrangement of high-strength intra-structural covalent bonds. This provides the basis for the material’s high thermal and mechanical performance, as well as interesting electrical properties which can be tailored to specific applications.

Continue readingCeramic 3D Printing: Latest Developments

Updated 11/11/21 to include the most accurate and up-to-date information.

Technical ceramics are ubiquitous in industrial manufacturing with a storied history of innovation and versatility. Manufacturers of some of the most hard-wearing and high-strength engineered ceramics worldwide are committed to pushing the envelope with regards to the capability of these novel materials. This has included fine-tuning the chemical composition of ceramic additives and raw materials to reduce the manufacturing costs of high-performance ceramics such as silicon nitride. All this, whilst still improving the material’s physical and thermal properties.

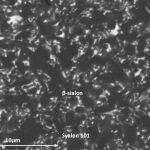

Continue readingComparing Syalon 101 to Other Types of Ceramic Materials

Syalon 101 is a Si-Al-O-N ceramic material with a similar crystallographic structure to beta-phase silicon nitride (β-Si3N4) which is also engineered for its extraordinary strength, toughness, and hardness characteristics. First envisaged as a cost-effective alternative to conventional silicon nitride, Syalon 101 can now compete with a broad range of established engineering ceramic materials.

Continue reading