Silicon nitride ceramics are a unique family of materials engineered for optimal efficiency in extremely demanding thermodynamic conditions. Several derivatives of the original beta-phase silicon nitride Syalon 101 have been designed for enhanced corrosion resistance or improved formability, but these outstanding mechanical and thermal properties still underline the performance of the overarching product line.

Continue readingKey Si3N4 Applications in the Chemical and Process Industry

The chemical and process industry is concerned with converting raw materials into semi-finished or finished products via thermochemical reactions. This covers an extensive range of industrial and commercial processes, including petroleum metering and petrochemical production of organic and inorganic polymers. Chemical and process industries are typified by chemical reactions of highly corrosive or erosive media at ambient or elevated temperatures.

Continue readingWhat is Slip Casting?

Mankind has been using moulds to manufacture ceramics for centuries. The precise origin of slip casting is still debated, with variations of the method observed in prehistoric Peruvian cultures and the ancient empires of the Mediterranean Sea. The French rather romantically coined the phrase coulage to describe the process of slip casting, which roughly translates as casting through shrinkage. This term is also associated with mass production, which is why the discovery of the technique is often dated centuries after indigenous peoples in Peru first used slip casting to construct simple panpipes.

Continue readingA Quick Introduction to Zirconia

Zirconia, or zirconium dioxide (ZrO2), is an advanced ceramic material which is used in a wide spectrum of applications, including abrasive and high-temperature processes, and in biomedical industries. This versatility comes down to the variable ZrO2 crystal structure. There are three disctint crystallographic phases of zirconia, and the properties of any given zirconia product depend upon which of those phases the material exists as.

Continue readingThe Modulus of Rupture of Silicon Nitride Ceramics

Sialon ceramics based on high-strength silicon nitride were engineered as a cost-effective solution to some of the most demanding thermal processing and mechanical industrial environments. A tetrahedral arrangement of silicon—nitrogen bonds substituted with the addition of aluminium and oxygen provides exceptional resistance to varied thermodynamic stresses, with enhanced resistance to corrosive attack. These properties are supplemented with high material strengths and physical integrity under applied forces.

Continue readingThe History of SiAlON Ceramics

Silicon nitride (Si3N4) is a high-performance refractory ceramic that can exist in three different crystallographic phases (α, β and γ), each displaying distinct thermodynamic properties. Each of these material phases is suitable for severe working conditions, and silicon nitride been used to manufacture high-temperature components in some of the most demanding industrial sectors worldwide. However, conventional sintering methods struggle to produce fully dense and complex silicon nitride components, and alternative techniques represent significant additional costs. SiAlON ceramics were engineered as a direct solution to these issues.

Continue readingInternational Syalons at ALUMINIUM 2018 – Düsseldorf

International Syalons will be attending ALUMINIUM 2018 in Düsseldorf , Germany on October 10th – 11th.

The trade fair, which takes place every 2 years, expects to attract more than 27,000 participants to meet with the 1000 exhibitors from 53 countries form around the world. ALUMINIUM is the world’s leading trade show for the aluminium industry and its main applications, and provides an excellent platform to unite producers, processors and end-consumers as well as technology suppliers.

International Syalons has supplied world leading advanced silicon nitride and sialon products to the molten metal handling industry for many years, utilising the outstanding chemical stability of our materials, particularly in contact with non–ferrous molten metals. The exceptional heat and corrosion resistant properties of Syalon ceramics have been utilised in a range of foundry products, including thermocouple protection sheaths, heater and riser tubes, ladles and other foundry products.

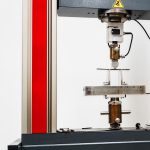

The Young’s Modulus of Silicon Nitride Ceramics

Silicon nitride-based ceramics are manufactured to exhibit exceptional thermodynamic properties and compete with conventional refractory materials for resistance to corrosive media and highly fluctuating thermal values. These material properties are associated with enhanced mechanical characteristics, including high strength profiles and outstanding resistance to physical stress.

Continue readingUsing Advanced Ceramics in the Aerospace Sector

Despite decades of radical material innovations in the aerospace sector, including the gradual adoption of advanced ceramics, aviation still operates on basic principles that were established over a century ago.

Thermal Expansion Coefficient of Sialon Ceramics

Technical sialon ceramics are manufactured for refractory applications, providing improved thermodynamic capacities over established industry materials such as alumina (Al2O3) and zirconia (ZrO2). Sialon ceramics are unique for their exceptional balance of thermal and mechanical properties, including superior thermal shock resistance and mechanical integrity under temperatures exceeding 1400°C (2552°F).

Continue reading