There are a myriad of different welding methods available today, such as metal inert or metal active gas (MIG/MAG) welding, high-frequency electric resistance welding (HF-ERW), shielded metal arc welding (SMAW), and many more. Technical ceramics can be used in tandem with practically any welding type, but they are typically restricted to high-value industrial processes due to their relatively high costs.

Continue readingFestive Holidays Notice

International Syalons (Newcastle) Ltd. offices will be closed from Friday 20th December until Monday 6th January.

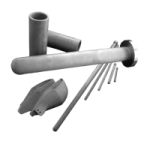

Why Use Silicon Nitride Nozzles for Blasting, Extrusion & Flow Applications

Silicon nitride (Si3N4) ceramics offer some of the best-in-class tribological properties, with outstanding nominal fracture toughness (Syalon 101 = 7.7 MPa m1/2) and exceptional strength characteristics (compressive, flexural, etc.). This combination gives silicon nitride outstanding wear resistance. The result is that a component fabricated from advanced ceramics like silicon nitride can withstand significant ongoing stress throughout its service life. This makes it the ideal ceramic material for dies, weld rolls, and cutting tools for example.

Continue readingHow Advances in Technical Ceramics Aid Industry 4.0

Updated 25/05/2022:

Digitalization and enhanced automation in industrial settings are now ushering in a fourth industrial revolution (Industry 4.0), which is fundamentally fuelled by advances in materials like technical ceramics.

Continue readingComparing Technical Ceramics: Sialon vs Zirconia

ww.syalons.com/materials/silicon-nitride-sialon/Technical ceramics like sialons and zirconia are among the most advanced materials ever engineered by mankind, enabling new application areas that were practically impossible before their commercial realisation. With many technical ceramics, there is a substantial overlap between their thermomechanical and chemical properties, which can complicate ideal material selection for distinct applications. In the case of sialons and zirconia however, the materials can be easily and respectively distinguished as a non-oxide and an oxide ceramic.

Continue reading25 Years of Service Anniversaries

Last week two long-serving employees of International Syalons (Newcastle) Ltd. celebrated their 25 Years of Service Anniversary.

A Guide to Technical Ceramics

Technical ceramics represent the cutting-edge of industrial materials. Engineered to withstand some of the harshest operating conditions ever conceived, technical ceramics are increasingly pushing the frontiers of market segments around the world.

Continue readingIan Denton

It is with great sadness that the Board of Directors announces the death of our ex-colleague Ian Denton after a long illness bravely fought.Continue reading

Technical Ceramics: Building the Internet of Things (IoT)

The Internet of Things (IoT) refers to a growing system of interconnectivity between devices and machinery – even those not typically associated with digital communications. Domestic markets have felt the impact of IoT devices most keenly, with the onset of intelligent virtual assistants (IVAs), smart energy monitoring, and WIFI-enabled appliances. Analysts predict that 26 – 100 billion IoT-enabled devices will be in service worldwide by 2020, a growing portion of which will rely on technical ceramics to function correctly. However, these estimates fail to reconcile the comparatively slow uptake of connected devices in industrial settings.

Continue readingAdvanced Ceramic Materials: Fundamental to the Future of AI?

The U.S. National Academy of Engineering (NAE) highlighted reverse-engineering of the human brain as one of the world’s greatest research challenges in the 21st Century. It was established as a priority alongside the economization of solar power and the realization of fusion on earth. By incorporating the aim of breaking down human cognitive abilities and building systems that can replicate them onto this list, the NAE essentially brought the field of artificial intelligence (AI) and machine learning out of an exclusively digital space and into the remit of materials science. Advanced ceramic materials, alloys, composites, polymers, and more, are now at the forefront of AI research efforts.

Continue reading